Imported hydraulic motor gear pump with impeller pressurized liquid supply

A technology of hydraulic motor and gear pump, which is applied in liquid variable capacity machinery, rotary piston type/swing piston type pump combination, rotary piston type/swing piston type pump components, etc., can solve the problem of low efficiency of hydraulic motor pump , hydraulic pump inefficiency, unfriendly man-machine, etc

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

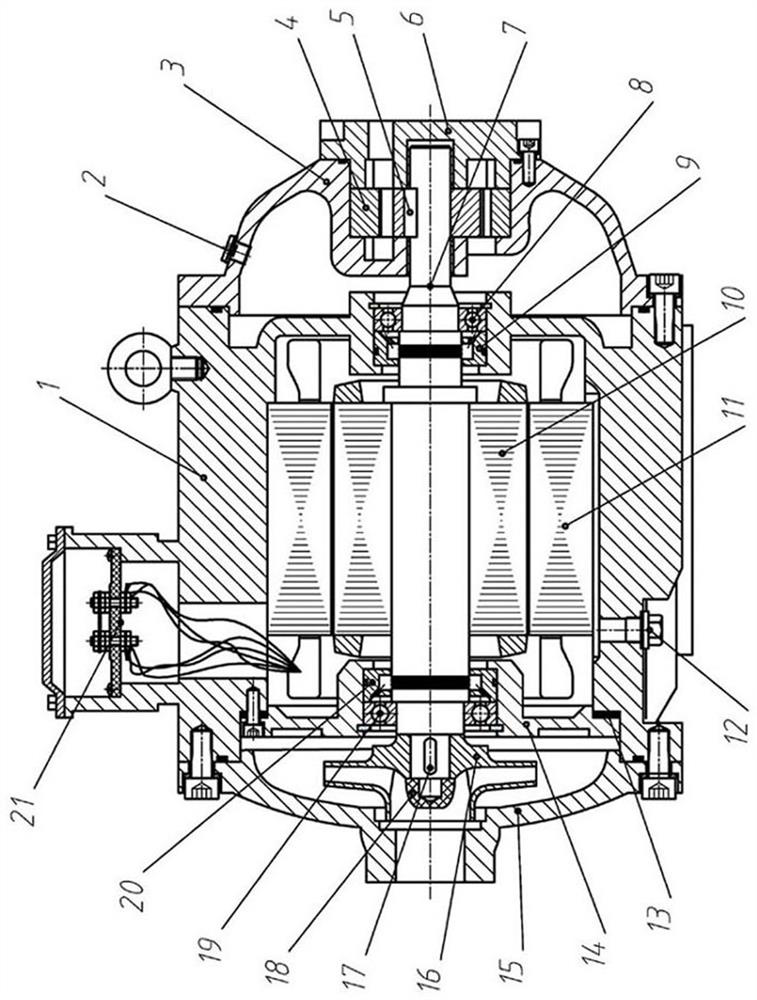

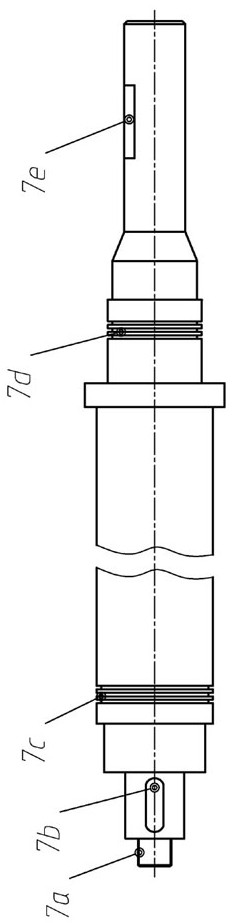

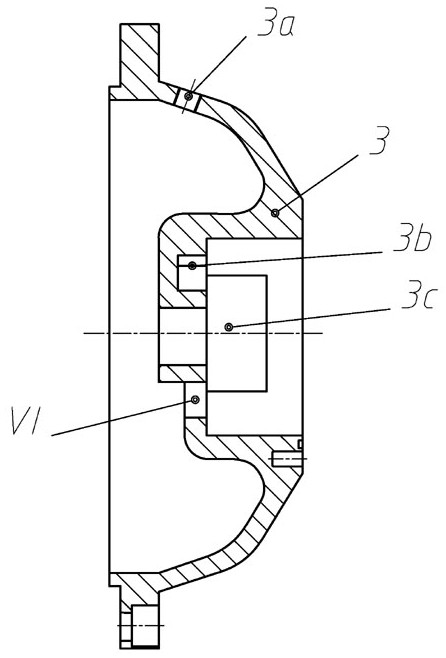

[0010] Such as Figure 1~Figure 5 As shown, the present invention is an imported hydraulic motor gear pump with impeller pressurization and liquid supply, including a housing 1, a vent hole screw plug 2, a front end cover 3, a gear set 4, a first flat key 5, and an oil outlet gland 6 , main shaft 7, first bearing 8, first seal 9, motor rotor 10, motor stator 11, oil drain plug 12, gasket 13, inner end cover 14, rear end cover 15, impeller 16, second flat Key 17, nut 18, second bearing 19, second seal 20, junction box assembly 21, the motor rotor 10 is installed on the main shaft 7 through interference fit, supported on the housing 1 by the first bearing 8 and the second bearing 19 Above, the gear set 4 is installed on the front end cover 3, connected with the main shaft 7 through the first flat key 5, the impeller 16 is arranged between the rear end cover 15 and the inner end cover 14, and connected with the main shaft 7 with the second flat key 17, Both ends of the main shaf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com