Hydrolysable toilet paper

A technology for toilet paper and pulp, applied in the field of toilet paper, can solve the problems of toilet paper clogging sewer pipes, difficult to dissolve toilet paper in water, low tensile strength of toilet paper, etc., and achieves the effects of accelerating hydrolysis, accelerating hydrolysis efficiency and speed of decay.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to make the technical means, creative features, objectives and effects achieved by the present invention easy to understand, the present invention will be further explained in conjunction with the embodiments below.

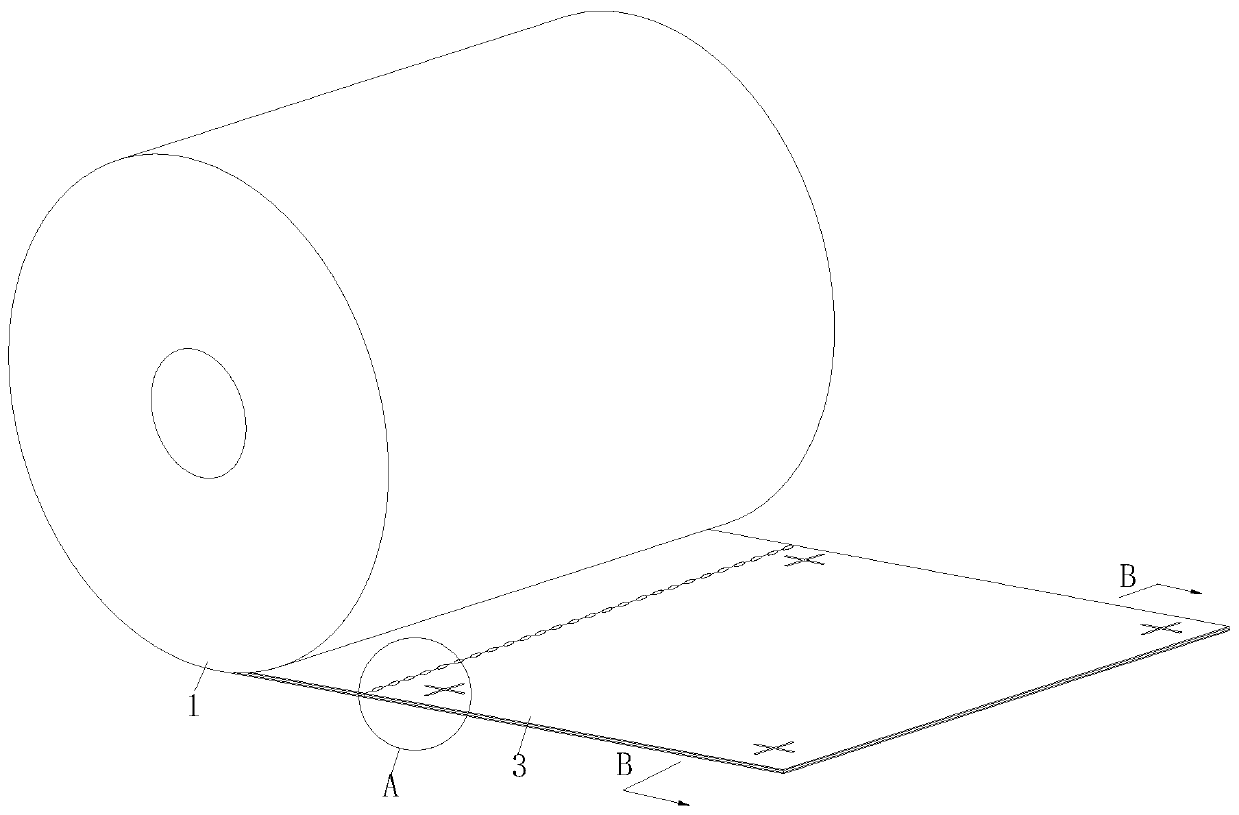

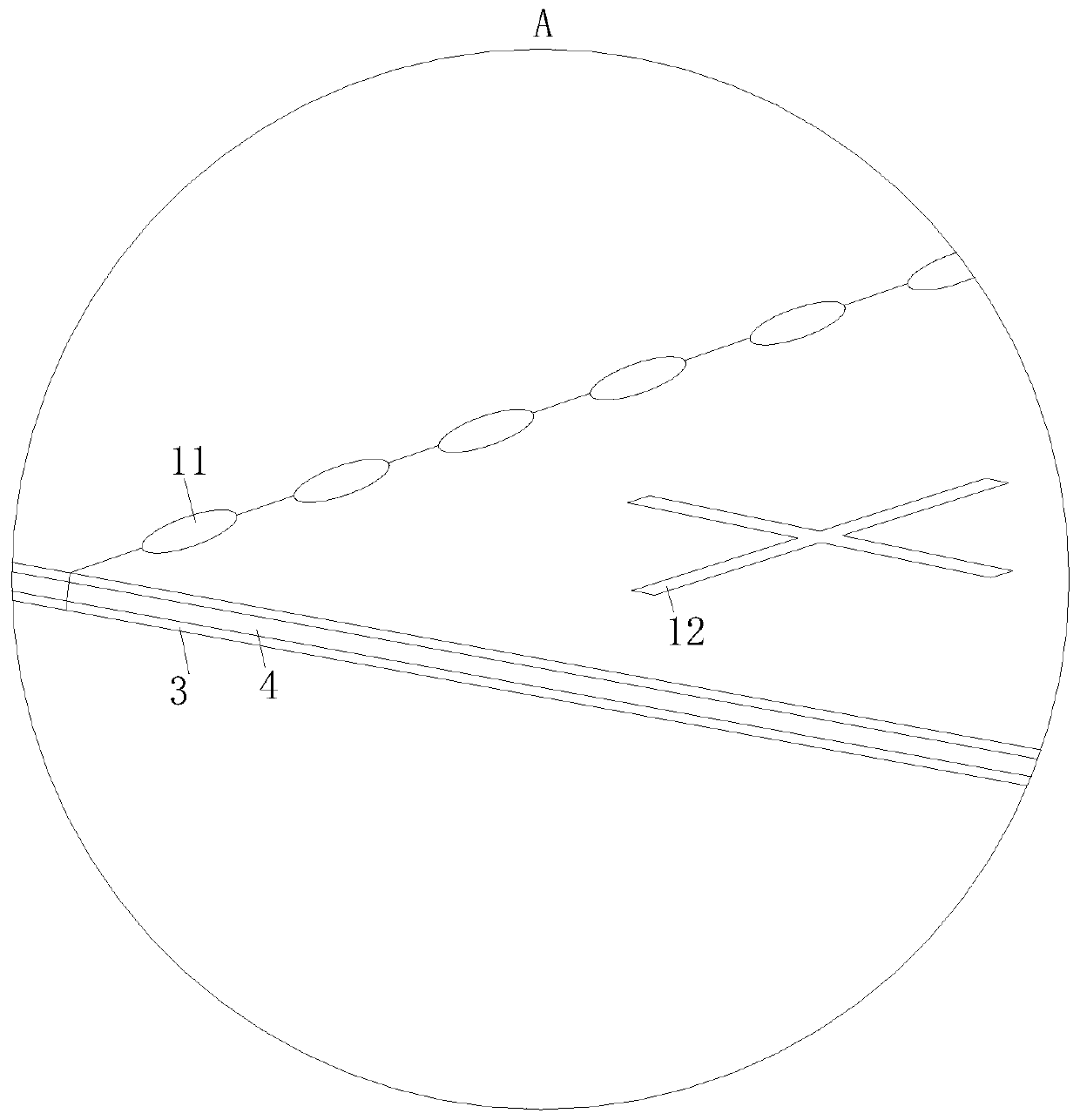

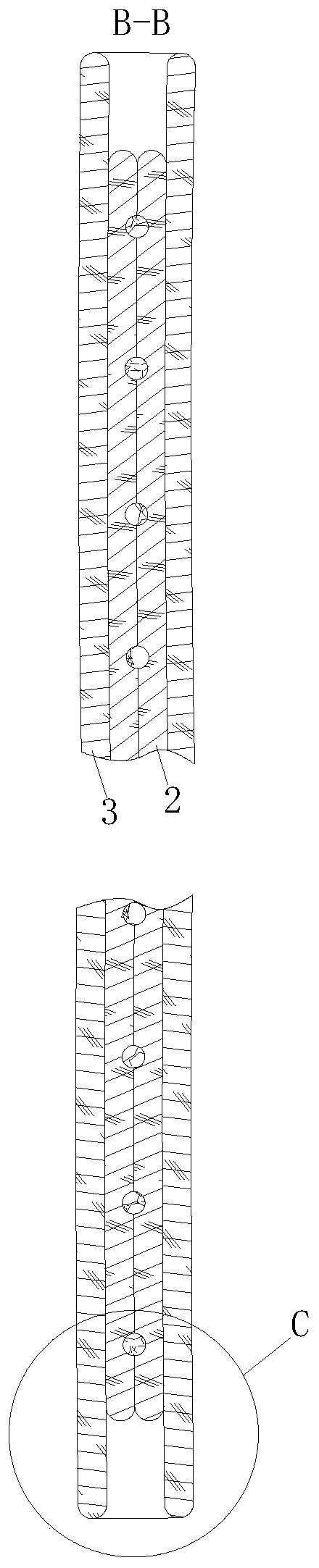

[0021] Such as Figure 1 to Figure 4 As shown, the hydrolyzable toilet paper according to the present invention includes a main body 1, the main body 1 presses the tearable strips 11 every 15CM length, each body 1 has a cross pattern 12 pressed at four right angles, and the main body 1 It is divided into four layers; the middle two layers are hydrolyzed layer 2, and the hydrolyzed layer 2 is made of refined paper pulp, decomposer and plant cellulose; the outer two layers are the wrapping layer 3; and the wrapping layer 3 is made of cotton pulp and Made of refined paper pulp; the cutting width of the hydrolyzed layer 2 is 13CM and the length is 15CM; the cutting width of the wrapping layer 3 is 15CM and the length is 15CM, and the hydrolyzed layer 2 i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com