Thermal power plant waste gas purification equipment

A thermal power plant, exhaust gas purification technology, applied in the direction of gas treatment, chemical instruments and methods, combined devices, etc., can solve the problems of poor purification effect of exhaust gas purification devices, and achieve the effect of improving the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

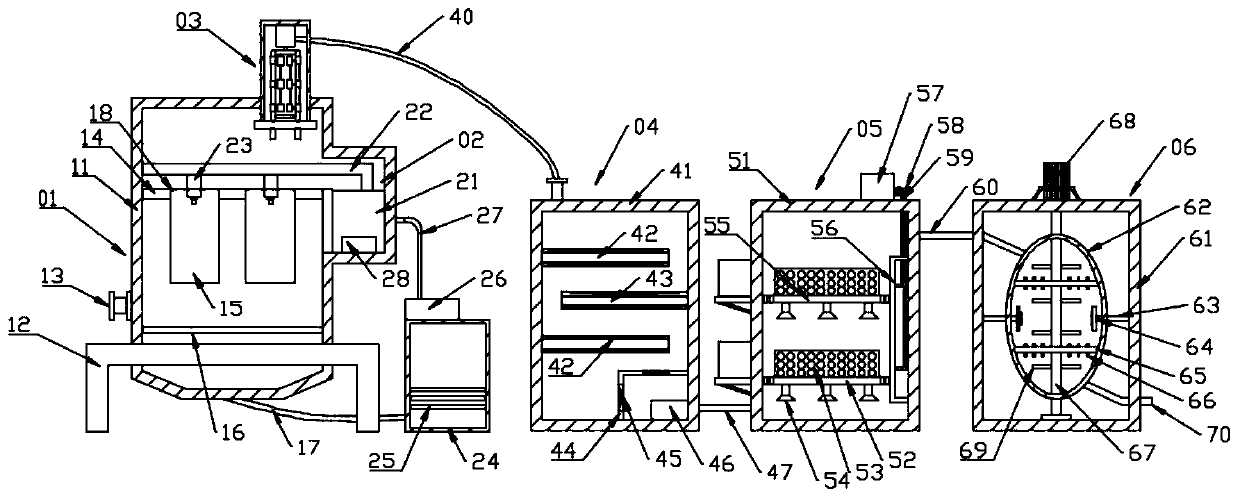

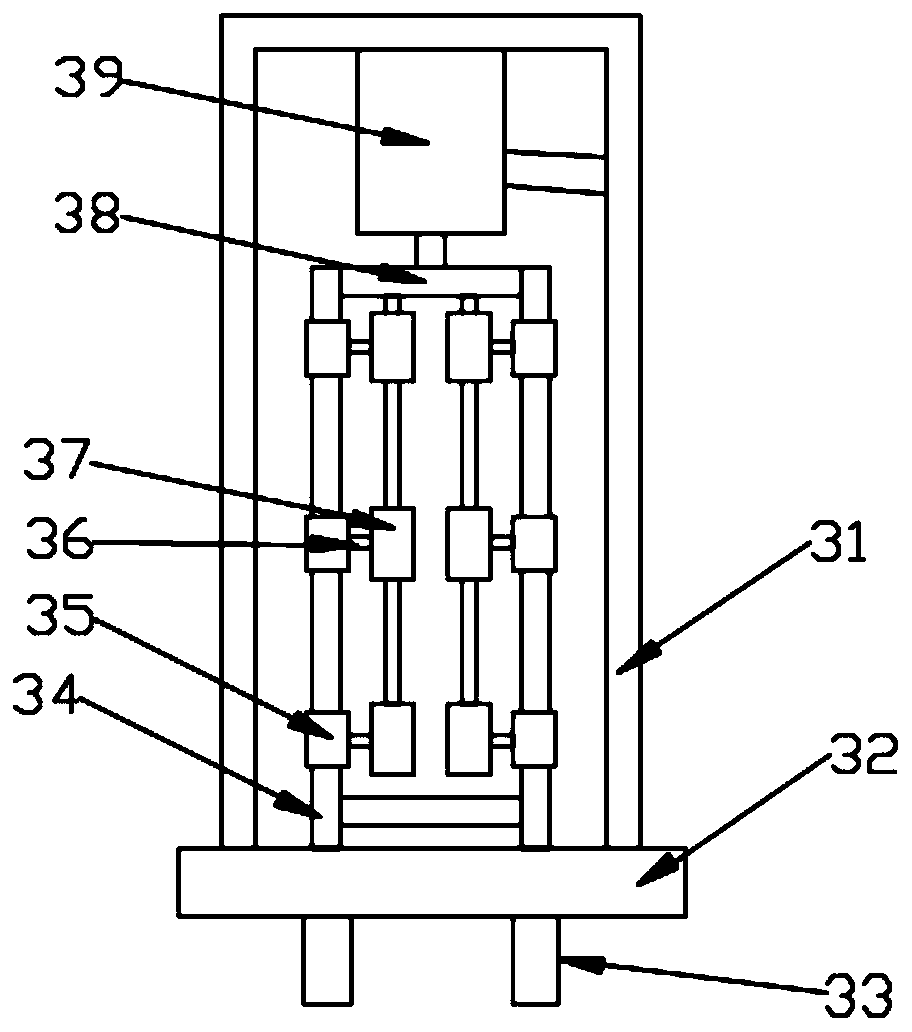

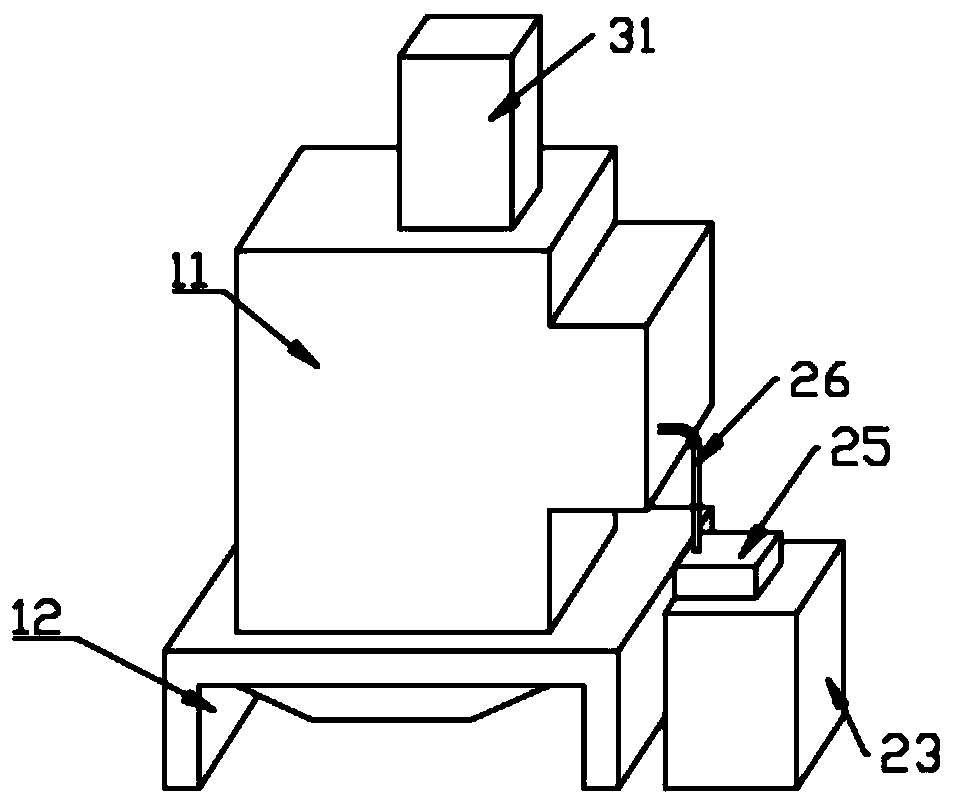

[0026] see Figure 1~3 , in an embodiment of the present invention, a thermal power plant exhaust gas purification equipment includes dust removal equipment 01 and purification equipment. The purification equipment includes a filter assembly 04, a reaction assembly 05, and a heating assembly 06. Coal mines are often used as fuel in thermal power generation. Contains a large amount of dust and harmful substances. Firstly, the dust is removed by the dust removal equipment 01, and then the exhaust gas is purified by the purification equipment, and then the dust and harmful substances in the exhaust gas are eliminated, so that the purified gas meets the emission requirements.

[0027] Further, the dust removal equipment 01 includes a dust removal box 11, the dust removal box 11 is placed on the base 12 for improving the stability of the dust removal box 11, a first air inlet 13 is provided on one side of the dust removal box 11, and the first air inlet The port 13 is used for the ...

Embodiment 2

[0034] A thermal power plant exhaust gas purification equipment, by setting dust removal equipment 01 and a purification device, it can not only remove a large amount of dust in the exhaust gas, but also process chemical substances, so that the discharged gas is cleaner; by setting dust removal equipment 01 The cleaning component 02 can not only clean the filter bag 15, but also wash the exhaust gas in the dust removal box 11. The used sewage is filtered through the first filter 25 and then enters the first water tank 21, so that it can be recycled, which is very simple Practical and save a lot of water resources.

[0035] The working principle of the present invention is: the gas enters the dust removal box 11 through the first air inlet 13, is filtered through the filter bag 15, is washed with water through the cleaning component 02, and then enters the adsorption component 03 through the through hole 18, and the cleaned Water recycling; after the gas enters the adsorption a...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap