Elevator brake iron core automatic machining production line

An elevator brake, automatic processing technology, applied in the direction of lighting and heating equipment, conveyor control devices, chemical instruments and methods, etc., can solve the problems of increasing production costs, heavy physical strength, affecting production efficiency, etc., to avoid collision accidents, reduce Reduce production costs and improve the effect of precise positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

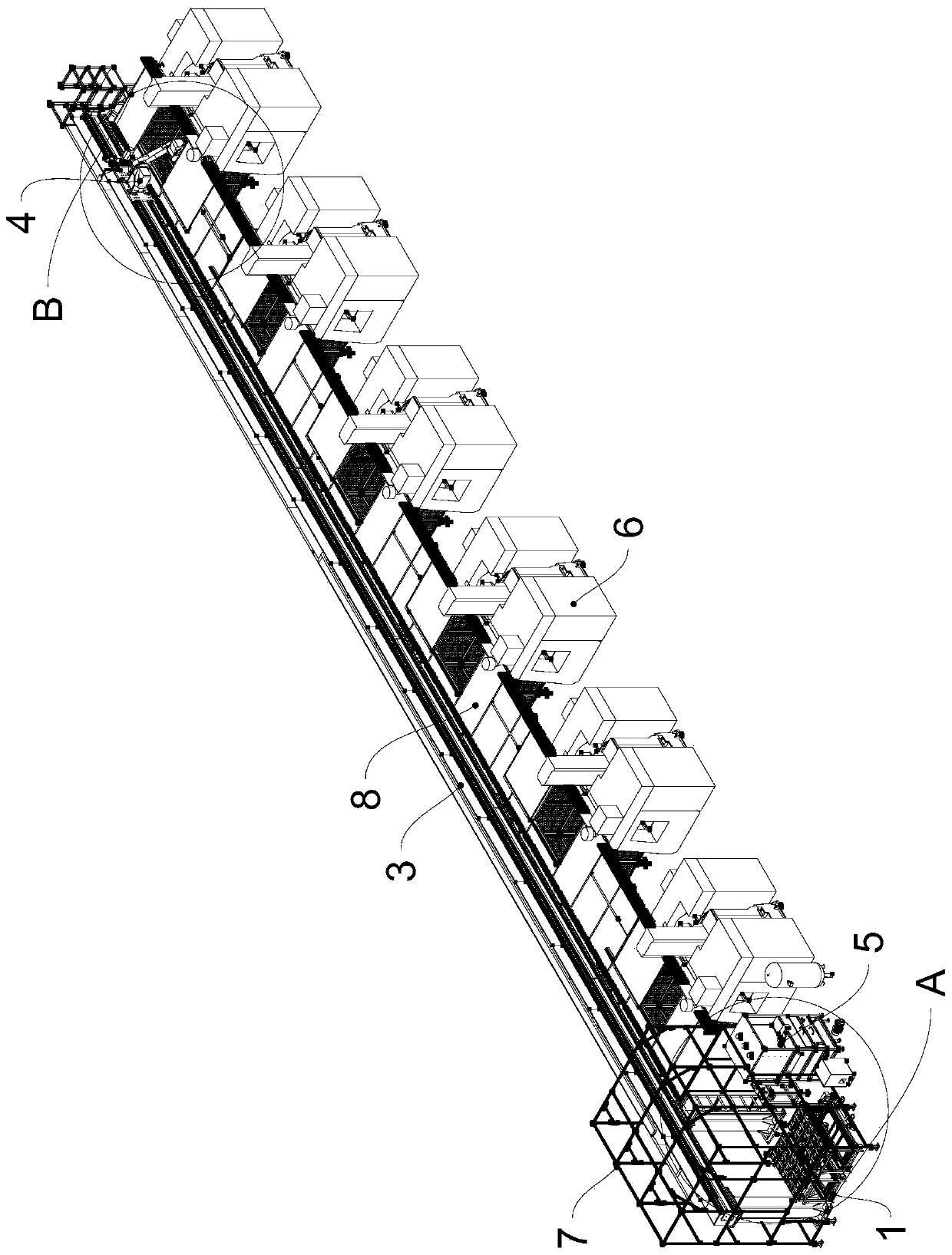

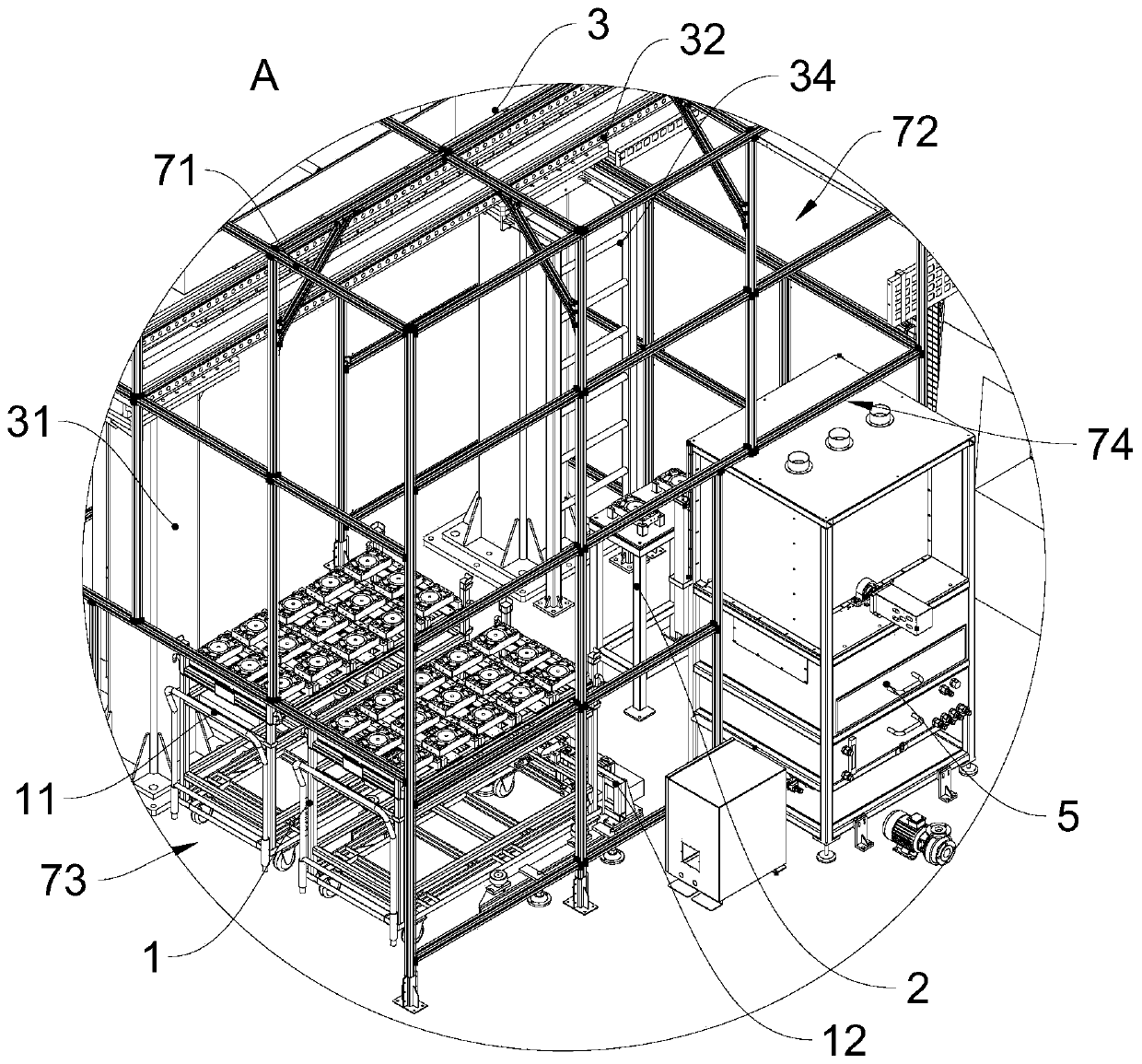

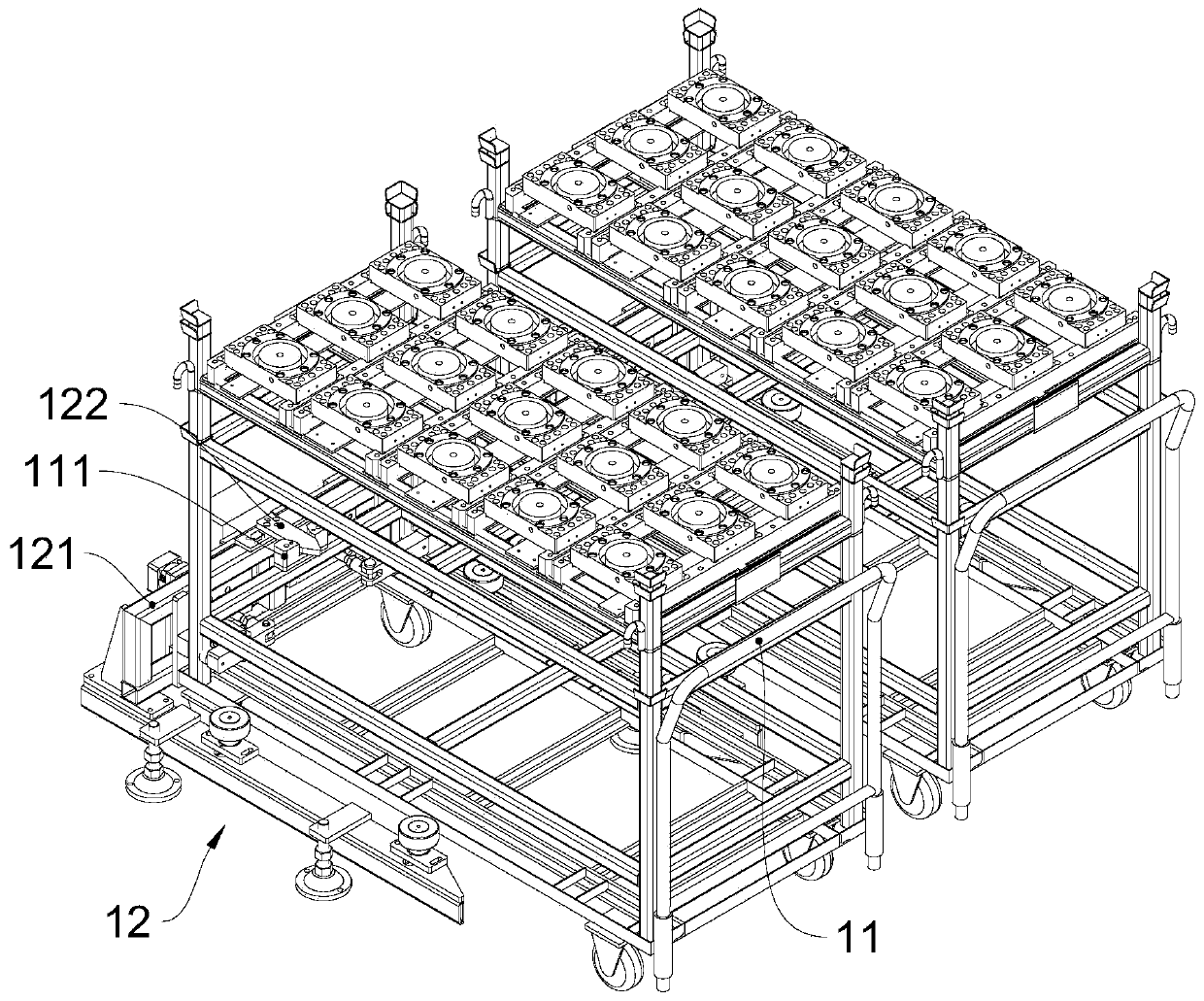

[0037] see figure 1 and figure 2 , figure 1 is a structural diagram of an embodiment of the present invention, figure 2 Yes figure 1 Enlarged image at A. The elevator brake iron core automatic processing production line includes a control unit, a material storage mechanism 1, a buffer table 2, a conveying mechanism 3, a robot loading and unloading mechanism 4, an automatic cleaning and drying device 5, and multiple processing center equipment 6. The control unit is respectively connected to the material The storage mechanism 1, the conveying mechanism 3, the robot loading and unloading mechanism 4, the automatic cleaning and drying device 5 are connected with the processing center equipment 6.

[0038]Conveying mechanism 3 comprises conveying frame 31 and two conveying guide rails 32, and two conveying guide rails 32 are positioned on conveying frame 31 horizontally and parallelly, and conveying guide rail 32 position is higher than the top of processing center equipment...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com