Deviation correction embossing rewinder for aluminum foil paper production

A technology of rewinding machine and aluminum foil paper, which is applied in the direction of winding strips, decorative arts, embossed decorations, etc., can solve the problems of rewinding machine deviation correction and low production efficiency, and reduce the swinging and sliding of material rolls. Flexibility and efficiency-enhancing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

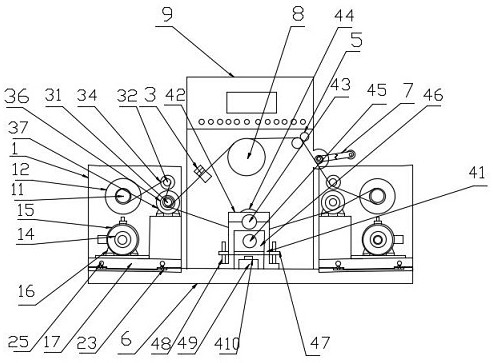

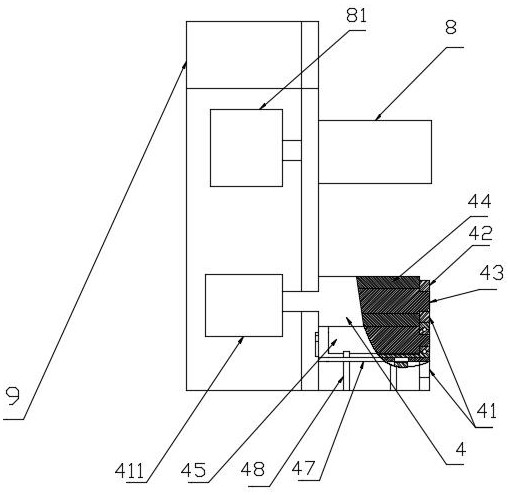

[0033] As shown in the figure, a deflection correcting embossing rewinder for aluminum foil production includes a tracking monitor 3, a brush edge mechanism 5 and a pneumatic constant pressure arm 7, and also includes an embossing mechanism 4 and two symmetrically arranged rewinding and unwinding machines. agencies and correction agencies. Wherein, the tracking monitor 3 is a photoelectric sensor and the brushing mechanism 5 is two cutting knives adapted to each other, which are used for cutting excess paper on both sides of the knife. The pneumatic constant pressure arm 7 is a pneumatic pressure arm used to tension the paper. When in use, the pneumatic constant pressure arm 7 is in contact with the paper to adjust the pressure according to the pressure to tension the paper. The rewinding and unwinding mechanism and the deviation correction mechanism are uniformly arranged in a rewinding and unwinding machine case 1, and the rewinding and unwinding machine case 1 is equipped w...

Embodiment 2

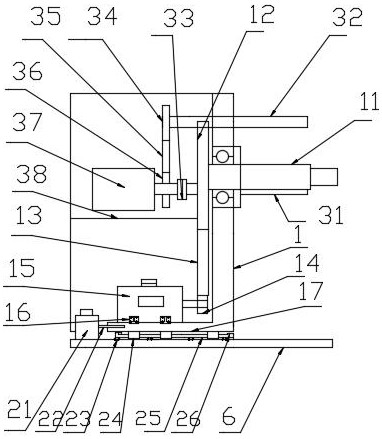

[0035] On the basis of the above-mentioned embodiments, in this embodiment, specifically, the bottom of the winding and unwinding mechanism is provided with a motor base plate 17, and the motor base plate 17 is fixedly connected with a motor fixing seat 16 to be provided with a winding and unwinding motor 15, and the winding and unwinding motor The rotating shaft of 15 is provided with the second gear 14, and the second gear 14 is connected with the first gear 12 by the first toothed belt 13, and the first toothed belt is an inner belt geared belt, not easy to slip. The first gear 12 is fixedly connected and arranged on the reel 11, the reel 11 is set as an inflatable shaft, the reel 11 is arranged in the outer wall of the rewinding and unwinding machine case 1 through a bearing transfer, and the reel 11 extends out of the rewinding and unwinding machine case 1. The pneumatic shaft is adopted to tighten, and the positioning is precise to reduce the swing of the material roll. ...

Embodiment 3

[0037]On the basis of the above-mentioned embodiments, in this embodiment, the deviation correction mechanism includes a motor bottom plate 17, and the motor bottom plate 17 is provided with a motor slot penetrating the motor bottom plate 17 near the tail, and is provided with a screw rod on the side of the notch. Threaded hole, the threaded hole is connected with a screw 22. The screw 22 is a high-precision ball screw, which makes the control more accurate. One end of the screw 22 is connected to the deviation correction motor 21 through a coupling. The deviation correction motor 21 is arranged in the motor slot and fixedly arranged on the fixed bottom plate 6 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com