Soil remediation agent prepared by using rice straw biomass charcoal as raw material and production method of soil remediation agent

A soil remediation agent and rice straw technology, which is applied in the field of contaminated soil remediation, can solve the problems of single chemical fixative remediation of pollution, large buffer capacity, low remediation effect, etc., and achieves good remediation effect, low cost, and various effects of remediating pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

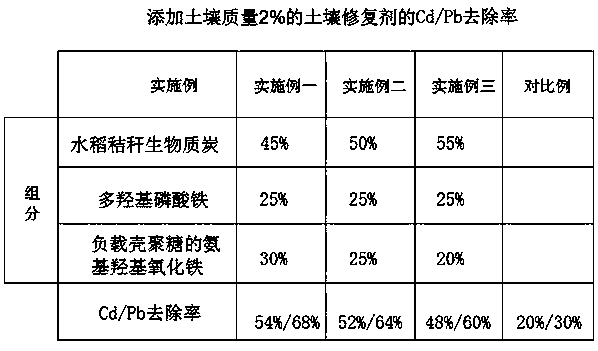

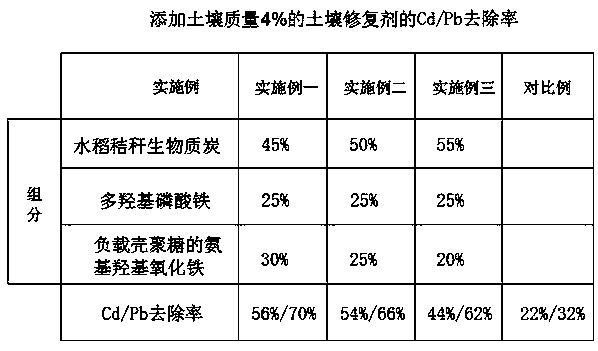

Embodiment 1

[0036] A kind of soil remediation agent with rice straw biochar as raw material, said soil remediation agent is composed of the following raw materials in mass percentage:

[0037] Rice straw biochar 45%;

[0038] Polyhydroxy iron phosphate 25%;

[0039] Chitosan-loaded amino iron oxyhydroxide 30%;

[0040] Wherein, the sum of the mass percentages of each raw material is 100%.

[0041] A production method of a soil repair agent using rice straw biochar as a raw material, specifically comprising the following steps:

[0042] Preparation of rice straw biochar,

[0043] S1: The rice straw is dried by natural air and then cut by a cutting machine. The length of the treated rice straw raw material is 2.5cm, and the moisture content is controlled at 18%;

[0044] S2: The biomass carbonization system was used to pyrolyze the biomass material at 500°C under anoxic conditions to obtain rice straw biochar, and the rice straw biochar was crushed into a powder with a particle size of ...

Embodiment 2

[0053] A kind of soil remediation agent with rice straw biochar as raw material, said soil remediation agent is composed of the following raw materials in mass percentage:

[0054] Rice straw biochar 50%;

[0055] Polyhydroxy iron phosphate 25%;

[0056] Amino iron oxyhydroxide loaded with chitosan 25%;

[0057] Wherein, the sum of the mass percentages of each raw material is 100%.

[0058] A production method of a soil repair agent using rice straw biochar as a raw material, specifically comprising the following steps:

[0059] Preparation of rice straw biochar,

[0060] S1: The rice straw is dried by natural air and then cut by a cutting machine. The length of the treated rice straw raw material is 2.2cm, and the moisture content is controlled at 16%;

[0061] S2: The biomass carbonization system was used to pyrolyze the biomass material at 500°C under anoxic conditions to obtain rice straw biochar, and the rice straw biochar was crushed into a powder with a particle siz...

Embodiment 3

[0071] A kind of soil remediation agent with rice straw biochar as raw material, said soil remediation agent is composed of the following raw materials in mass percentage:

[0072] Rice straw biochar 55%;

[0073] Polyhydroxy iron phosphate 25%;

[0074] Chitosan-loaded amino iron oxyhydroxide 20%;

[0075] Wherein, the sum of the mass percentages of each raw material is 100%.

[0076] A production method of a soil repair agent using rice straw biochar as a raw material, specifically comprising the following steps:

[0077] Preparation of rice straw biochar,

[0078] S1: The rice straw is dried by natural air and then cut by a cutting machine. The length of the treated rice straw raw material is 2.0cm, and the moisture content is controlled at 12%;

[0079] S2: The biomass carbonization system was used to pyrolyze the biomass material at 500°C under anoxic conditions to obtain rice straw biochar, and the rice straw biochar was crushed into a powder with a particle size of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com