Impact acceleration sensitive valve for shock absorber

A technology of sensitive valves and shock absorbers, which is applied in the field of vehicle vibration reduction, can solve problems such as unresolvable technical contradictions, restrictions on the improvement of vehicle ride comfort, and the inability to distinguish working conditions with a single state variable, so as to increase the suspension reset speed and reduce suspension. The effect of improving the vehicle ride comfort and attitude stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

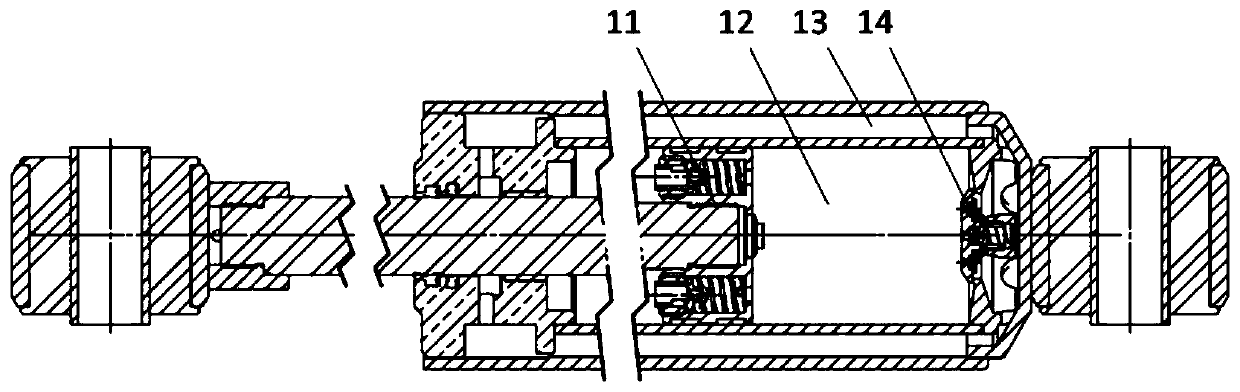

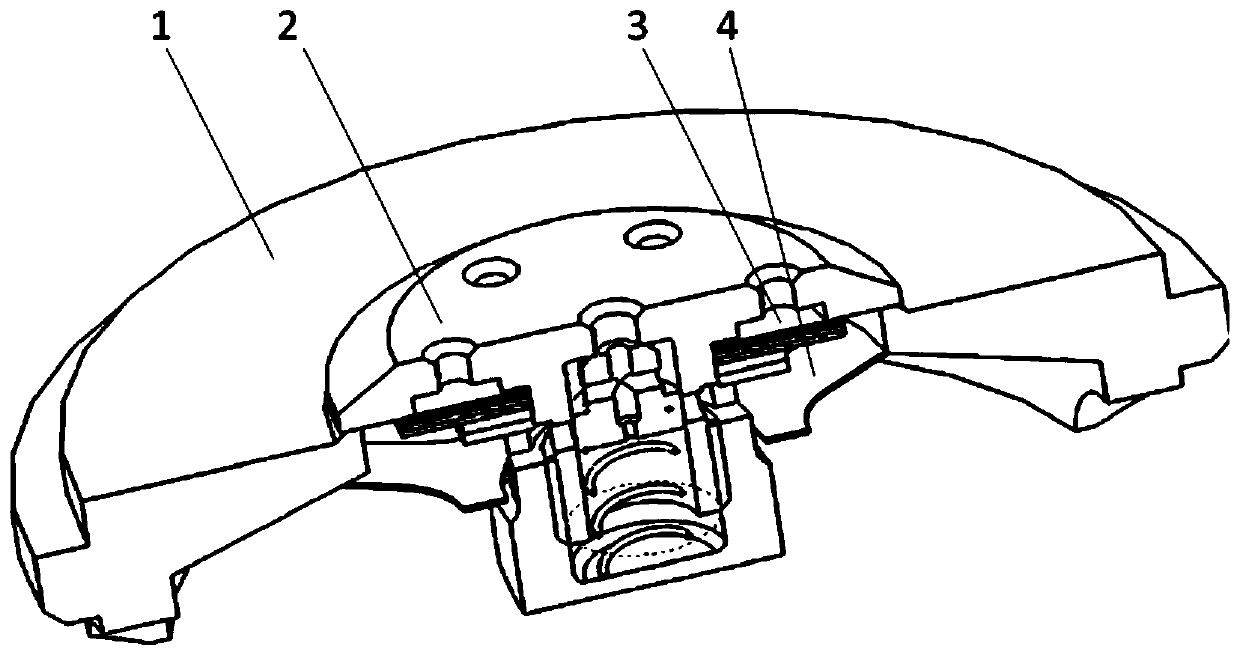

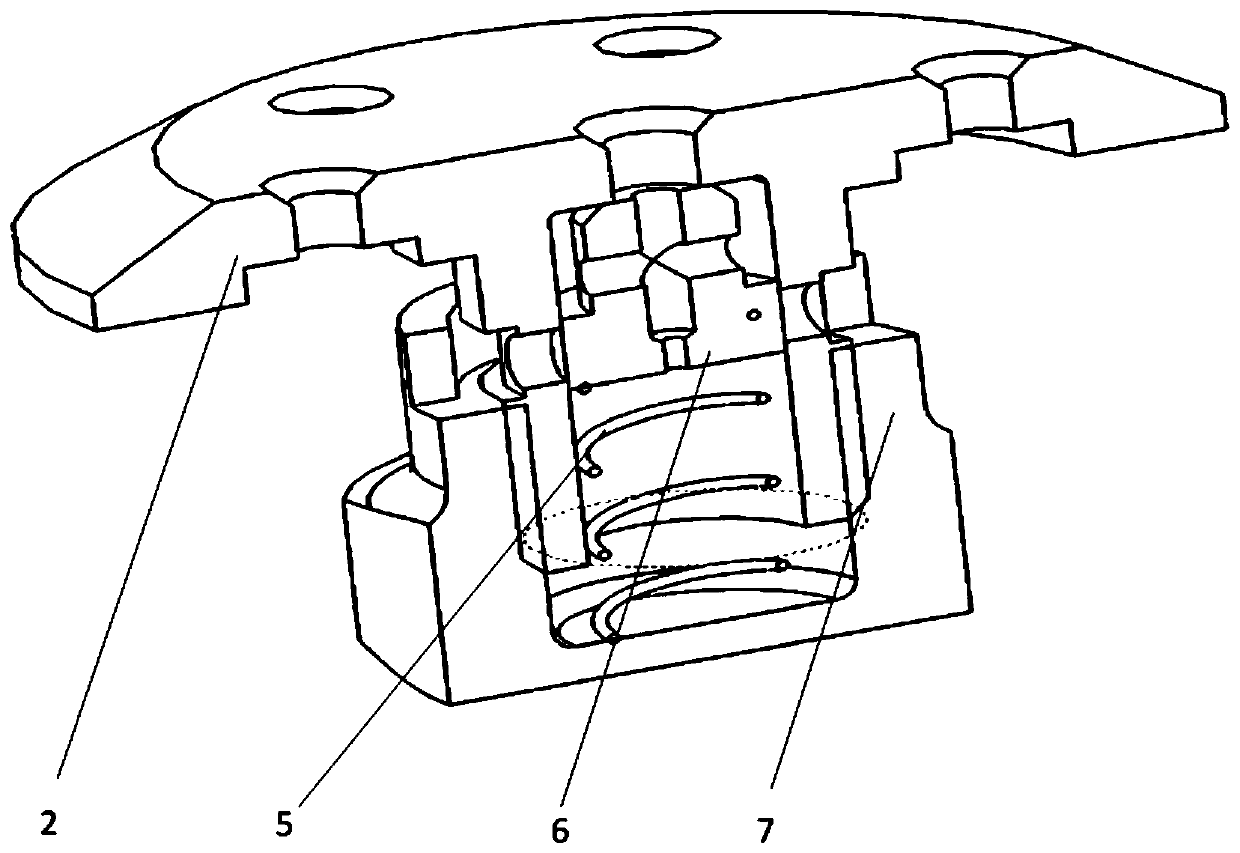

[0051] Such as Figure 1-Figure 3 As shown, the sensitive valve of this embodiment is installed on the bottom valve assembly of the shock absorber. The bottom valve assembly is used to control the flow between the working chamber and the compensation chamber, which has a crucial influence on the compression damping of the shock absorber.

[0052] The valve stem in this sensitive valve is connected with the shock absorber housing and the wheel through the bottom valve assembly. When the wheel is subjected to a strong impact from the ground, the valve stem will move upwards, and the slider will move relatively due to inertia. The valve stem moves downward, so that the radial through hole of the slider communicates with the radial through hole of the valve stem. It is equivalent to the increase of the orifice area between the high pressure chamber and the compensation chamber of the shock absorber, the decrease of the pressure difference between the high and low pressure chamber...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com