High-sensitivity fiber bragg grating pressure sensor based on square diaphragm

A technology of pressure sensor and optical fiber grating, which is applied in the field of optical fiber grating sensing and detection, can solve the problems of low deflection and low sensitivity in the center of the circular diaphragm, and achieve good shock resistance and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in further detail below in conjunction with the accompanying drawings.

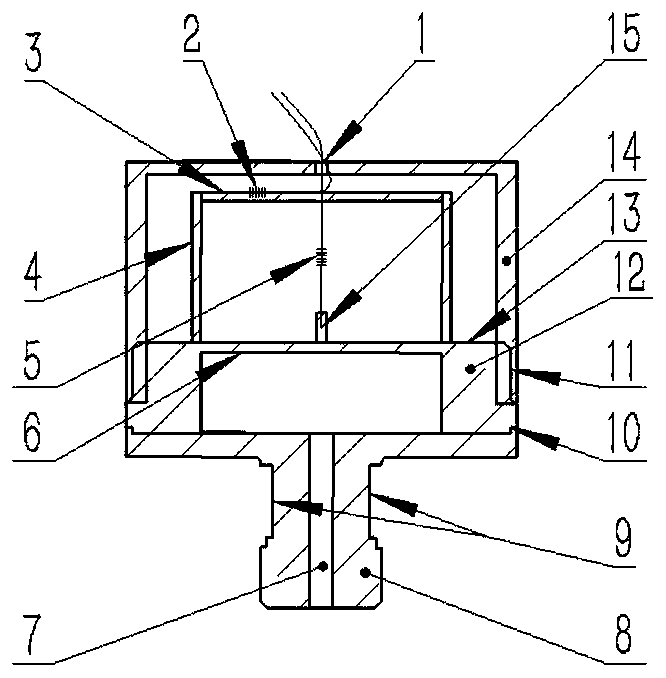

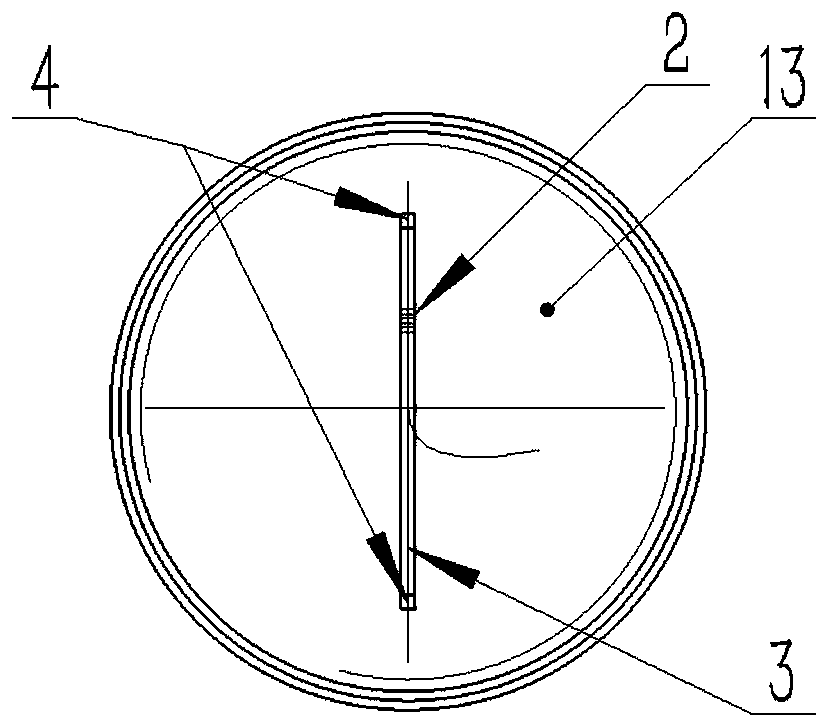

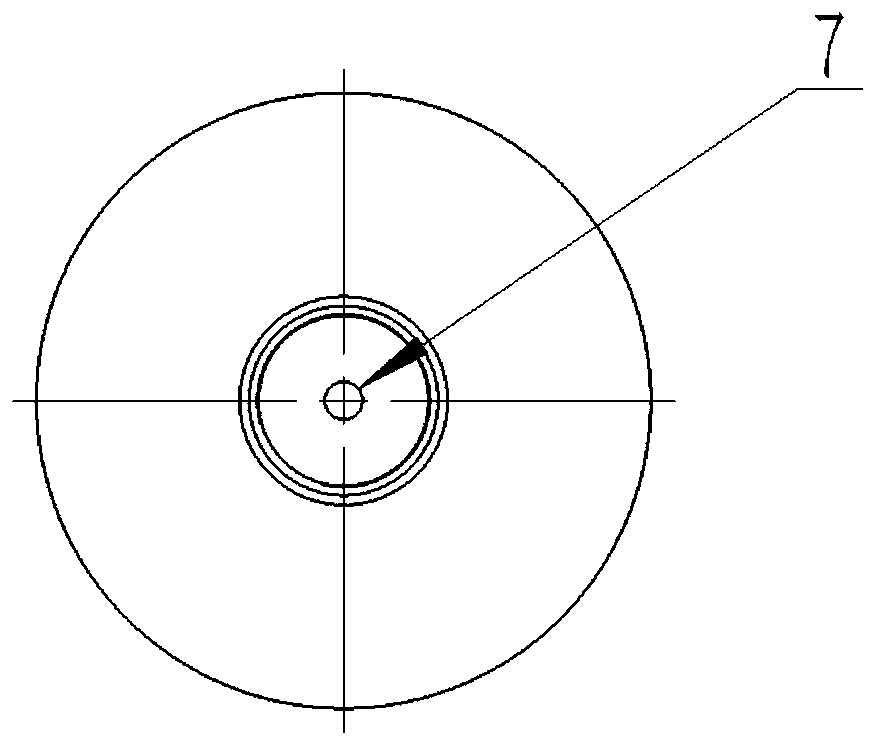

[0025] Such as figure 1 and figure 2 As shown, the high-sensitivity fiber Bragg grating pressure sensor based on the square diaphragm provided by the present invention includes: a protective cover 14, which is a columnar cylindrical structure, and the top center is provided with a fiber grating 5 for measuring pressure and a fiber Bragg grating for temperature measurement 2 Outlet hole 1 for the pigtail. The middle part 12 is a cylindrical cylindrical structure, and its top surface has a square pressure-bearing diaphragm 6 that directly senses the external oil and gas pressure; a stress transmission rod 15 installed in the center of the square pressure-bearing diaphragm 6; a vertical beam 4; the free end of the vertical beam 4 is provided with a crossbeam 3; the temperature measuring fiber grating 2 installed on the upper surface of the crossbeam 3; the pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com