A Hybrid Plasmon Resonator with High Quality Factor

A technology of plasmonic resonator and high quality factor, which is applied in the field of resonators and transmission lines, can solve the problems that the plasmonic quality factor and resonance strength are difficult to have at the same time, and achieve considerable application prospects, high-sensitivity sensing, Effect of Enhancing Quality Factor and Resonance Strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

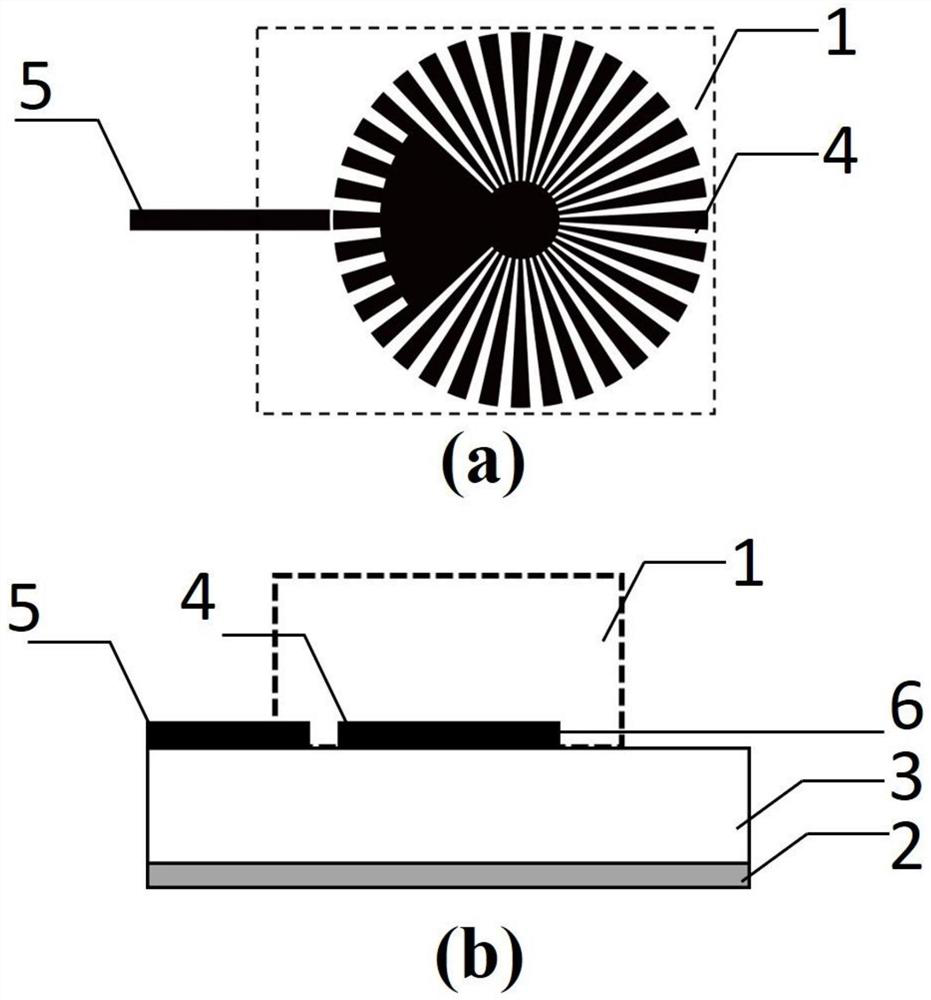

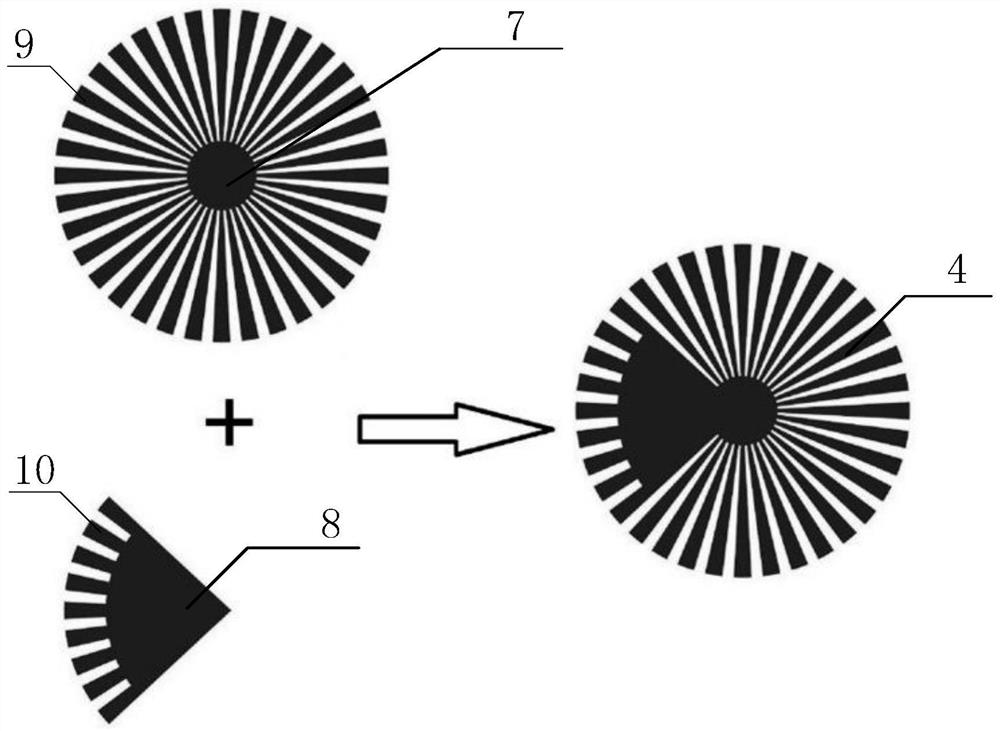

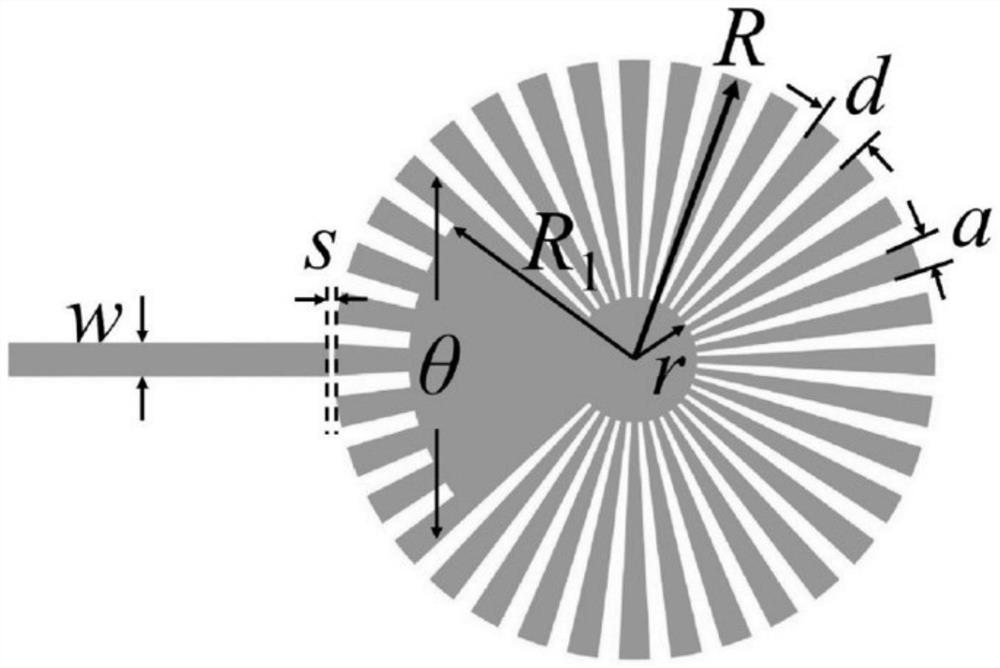

[0047] The structure of the hybrid plasmonic resonator in this embodiment is as follows Figure 1-3 shown. The geometric parameters are: R=12mm, r=2.5mm, d=2.09mm, a=0.6*d=1.26mm, R 1 =9mm, θ=86°. The structure is excited by a 50Ω microstrip line, the dielectric substrate 3 is a 0.5mm thick F4B plate, its dielectric constant is 2.65, the loss tangent is 0.001, the width of the microstrip line is w=1.34mm, and the gap between the microstrip line and the resonator is s = 0.2 mm.

[0048] Simulation S of artificial localized surface plasmon resonator (SLSP), sector resonator (PR) and hybrid plasmon resonator (Hybrid) (resonator body) disclosed by the present invention 11 curve like Figure 4 shown. The resonant peak of the hybrid plasmonic resonator is at 9.16GHz, S 11 =0.04 (-22.8dB), quality factor Q=142. The artificial localized surface plasmon resonator (SLSP) is in the magnetic plasmon mode at 8.96GHz, and Q=44.8. Due to the superposition of two resonators, the artif...

Embodiment 2

[0055] Sensing area 1 is a closed area or an open space covered by an outer wall, and its material can be gas, liquid, solid or a mixture of the three; the refractive index of the sensing area material is in the range of (1,3).

[0056] This embodiment adopts the same geometric structure as that of Embodiment 1, for the application of the resonator in the sensing of different dielectric environments (refractive index range 1-1.8), and the electromagnetic simulation results are as follows Figure 7 . Figure 7 is the reflectivity of the resonator body (S 11 ) spectrum; where the black solid line is the reflectivity S when the refractive index of the sensing area is equal to 1 (air) 11 . When the refractive index of sensing region 1 gradually increases, we can see that S 11 Redshift of spectral resonant frequency, frequency sensitivity to refractive index change is 1.1GHz.RIU -1 . The artificial surface plasmon resonator has a sensitivity of 0.27GHz.RIU -1 . Therefore, th...

Embodiment 3

[0058] This embodiment adopts the same geometric structure as Embodiment 1, and it detects the thickness of the F4B dielectric plate, and its experimental test results are as follows Figure 8 , the hollow circle, solid circle, hollow triangle and solid triangle in the figure are S when the thickness of the F4B dielectric substrate is 0.5mm, 1mm, 1.5mm and 2mm respectively 11 Curve, the black solid line is the S of the resonator body when the dielectric substrate is not covered 11 spectrum. It can be seen that as the thickness of the surface dielectric material increases, its resonance peak presents an obvious red shift.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com