Compound pelletized grass seed production and processing process and application

A processing technology and pelletizing technology, which is applied in the agricultural field, can solve the problems of increased bacterial carrier rate, seeds easily drifting with the wind, and unsuitable for mechanized sowing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

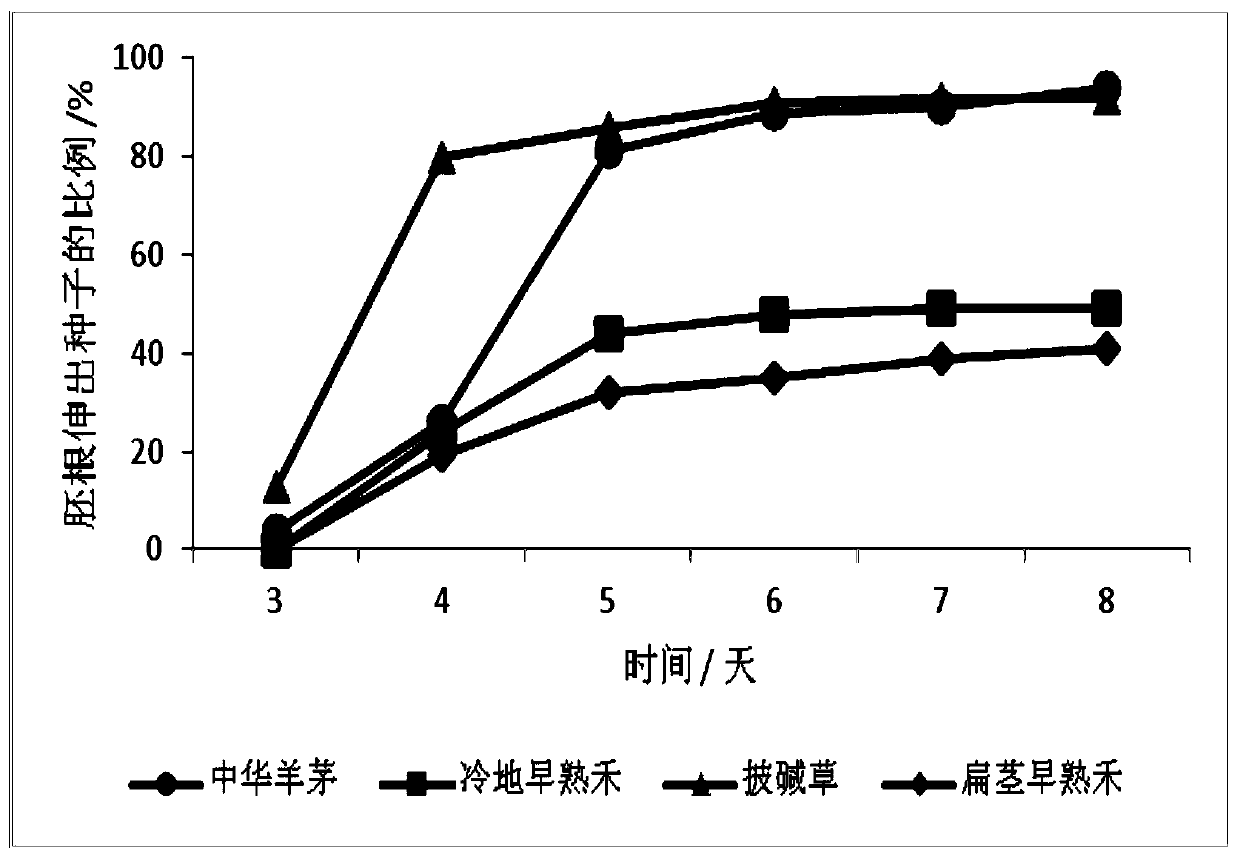

[0033] The present invention discloses a composite pelletized grass seed production and processing technology and its application. In the present invention, four kinds of seeds have been tested, namely: Poa crymophila Keng and Festucasinensis keng. ), Elymus dahuricus Turcz and Poa pratensis Keng were all purchased from Huang Zhongtian Xing Grass Industry Co., Ltd. In the present invention, 4 kinds of pelletized materials are selected, which are marked as A1, B, R, and W respectively. Among them: A1 was presented by the Dutch Astec Seed Technology Company, the full name of the material is Astec A1; B and R are imported materials from Germany, the trade names are Bellerophpn and Rolexo respectively, and W is Jingyan Agronomics ( Beijing) Seed Industry Technology Co., Ltd. self-made material, the full name is JYYN-W, the company specializes in vegetable seed coating. The specific pelletization method is as follows:

[0034] S1: Seed selection

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com