Machining device for ultra-long and ultra-large steel reinforcement framework and hoisting device and method

A steel skeleton and processing device technology, which is applied in the erection/assembly of bridges, transportation and packaging, load hanging components, etc. Precise installation location and improved construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

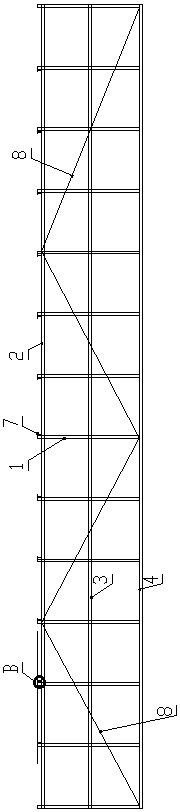

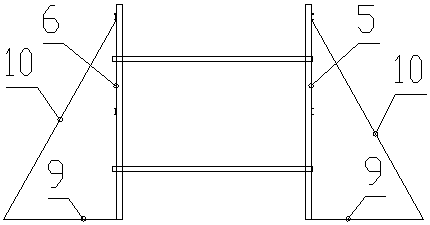

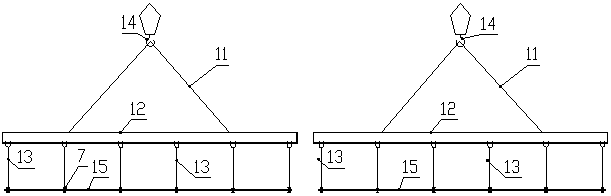

[0052] Such as Figure 1 to Figure 8 As shown, the ultra-long and super-large steel frame processing device of the present invention includes two rows of uprights correspondingly arranged in front and back, each row of uprights includes a plurality of uprights 1, and the distance between adjacent uprights 1 in each row of uprights is 2 ± 0.1 meters , the total length of each row of uprights is greater than or equal to the length of the steel skeleton to be made; the uprights 1 can be channel steel or section steel of different types to increase structural rigidity. The height of each vertical pole 1 is 0.5 ± 0.1 meters greater than the design height of the ultra-long super-large steel skeleton 20 to be produced;

[0053] The upper, middle and bottom ends of each row of vertical bars are respectively connected with upper horizontal connecting rod 2, middle horizontal connecting rod 3 and lower horizontal connecting rod 4; upper horizontal connecting rod 2, middle horizontal con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com