Construction method of long-distance concrete pouring for high pile wharf

A construction method and high-pile wharf technology, applied in construction, sea area engineering, water conservancy engineering, etc., can solve the problems of high dependence on concrete workability, waste of time and labor, and more waste of concrete, so as to improve the construction speed and quality, save manpower and material resources, and make full use of on-site resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

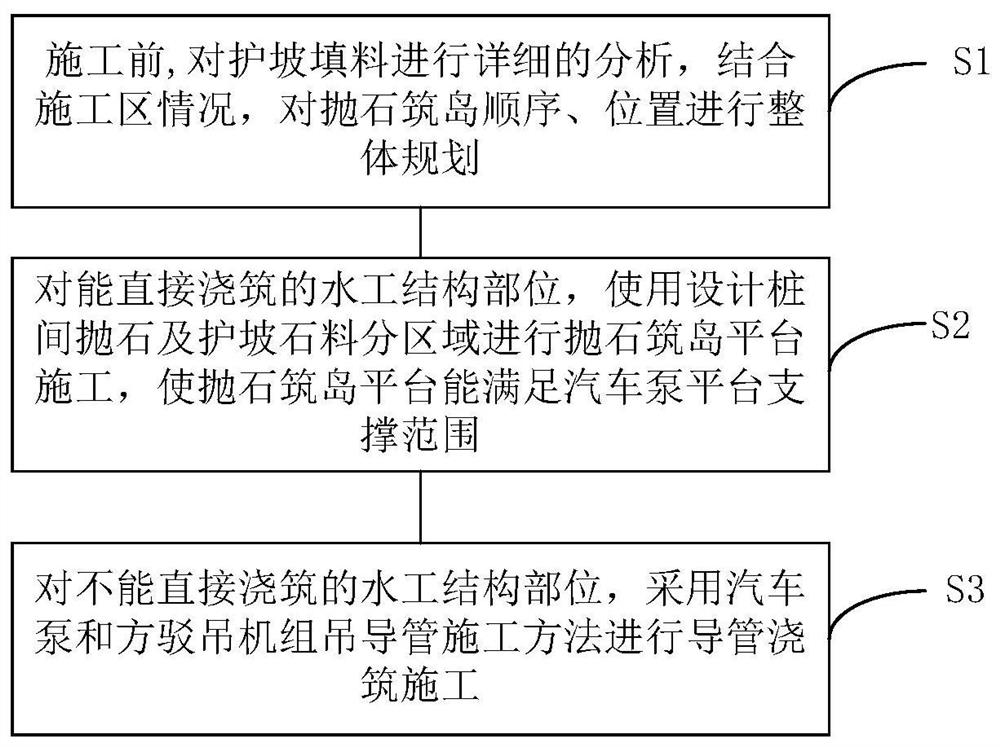

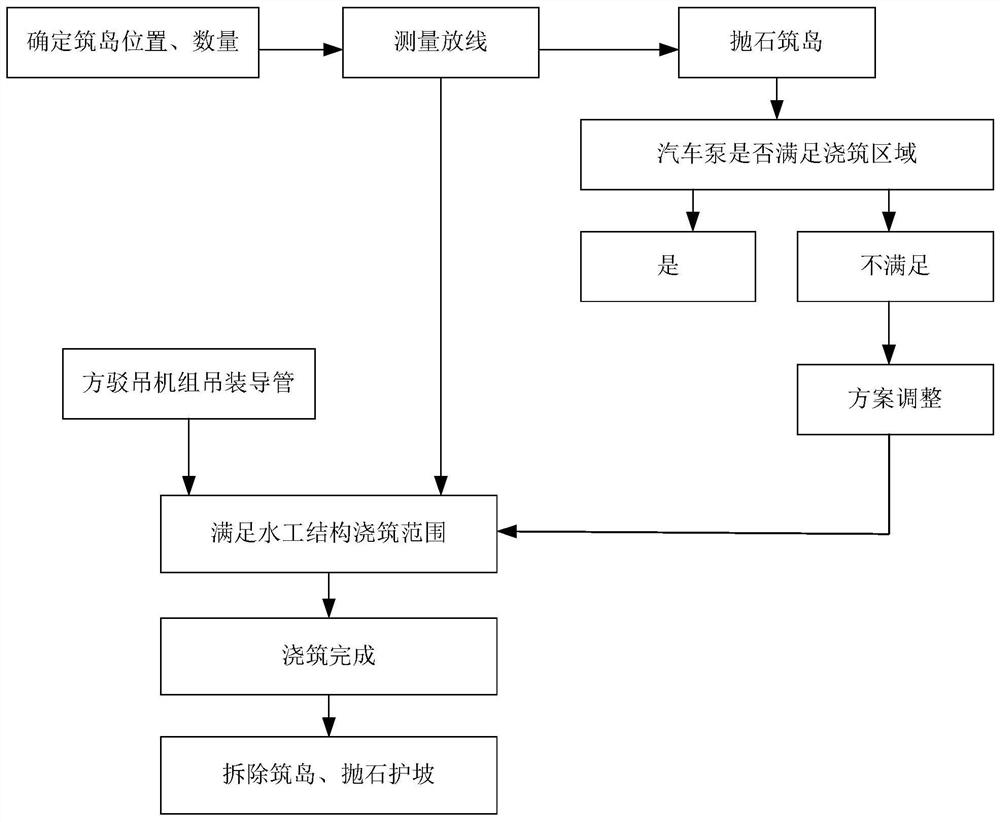

Method used

Image

Examples

Embodiment Construction

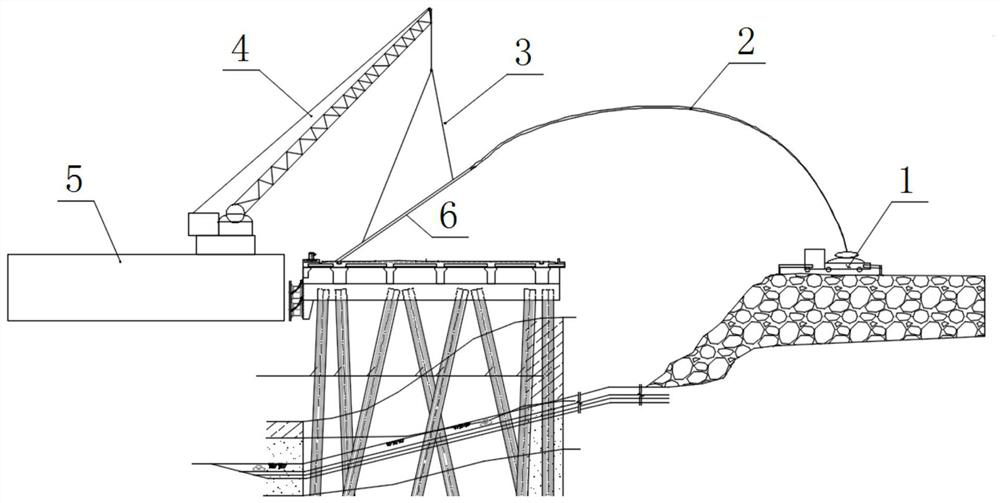

[0039] Embodiments of the present invention are described in detail below, examples of which are shown in the drawings, wherein the same or similar reference numerals designate the same or similar elements or elements having the same or similar functions throughout. The embodiments described below by referring to the figures are exemplary and are intended to explain the present invention and should not be construed as limiting the present invention.

[0040] The traditional ground pump pouring process mainly uses concrete ground pumps, which are construction equipment that rely on pressure to transport concrete through pipelines. It is equipped with special pipelines, which can continuously complete horizontal and vertical transportation of concrete along the pipelines, and The production of ready-mixed concrete is combined with pumping construction, and the concrete mixer truck is used for intermediate operation, which can realize continuous pumping and pouring of concrete. H...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com