A Miniaturized Negative Compensation Mid-Wave Cooled Infrared Continuous Zoom Optical System

An optical system and compensation technology, applied in optics, optical components, instruments, etc., can solve the problems of shortening the total length of the optical system, reducing the length of the optical system, increasing the structure of the field of view diaphragm, etc., to reduce the length of the optical system , reduce beam energy loss, and increase the effect of field diaphragm structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

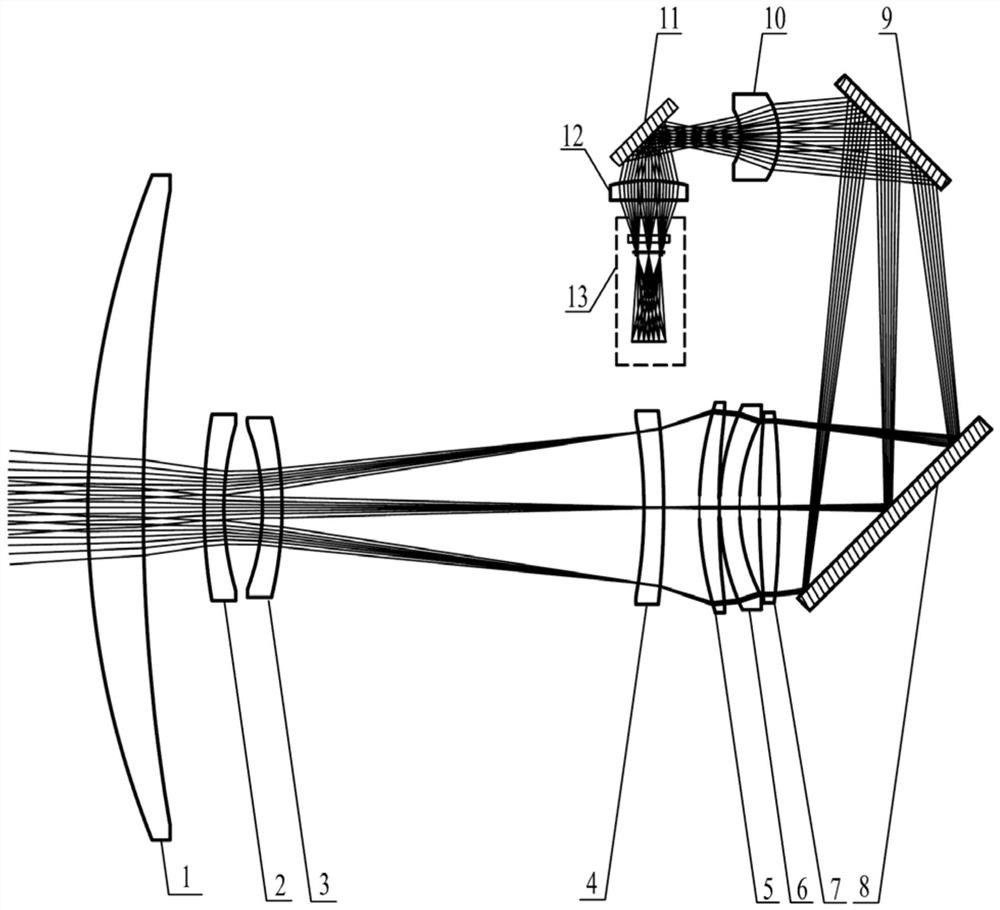

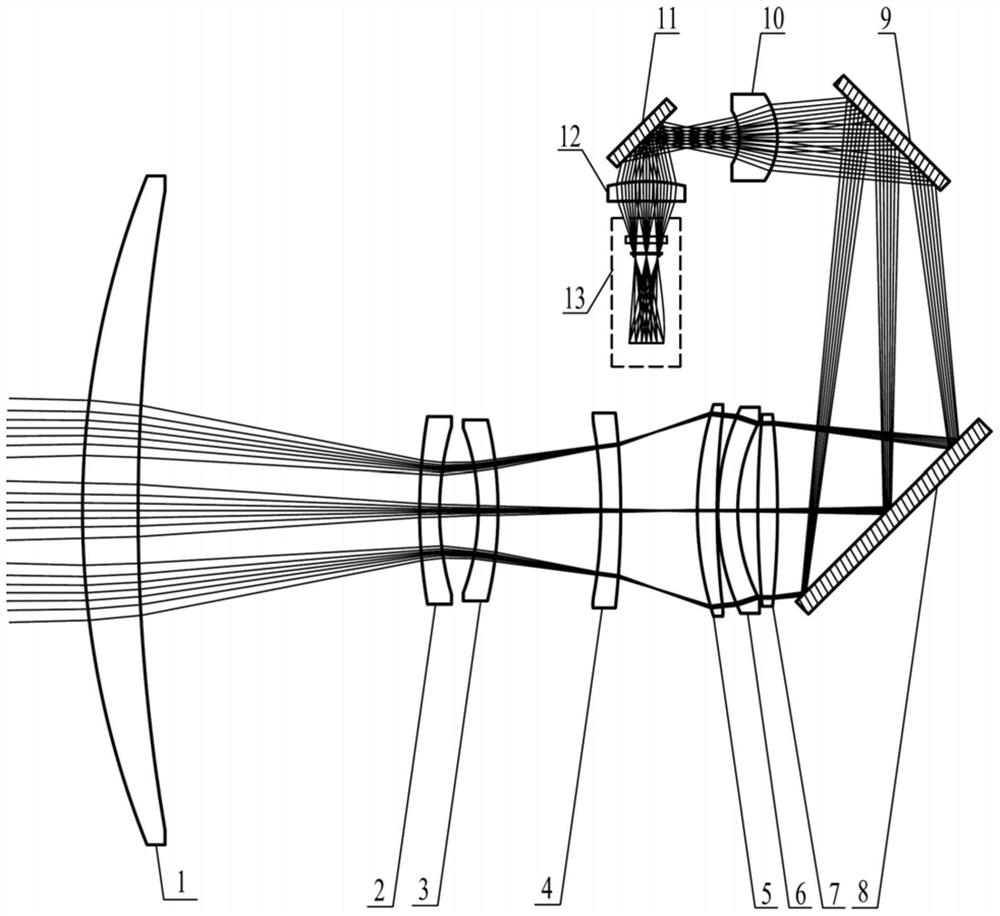

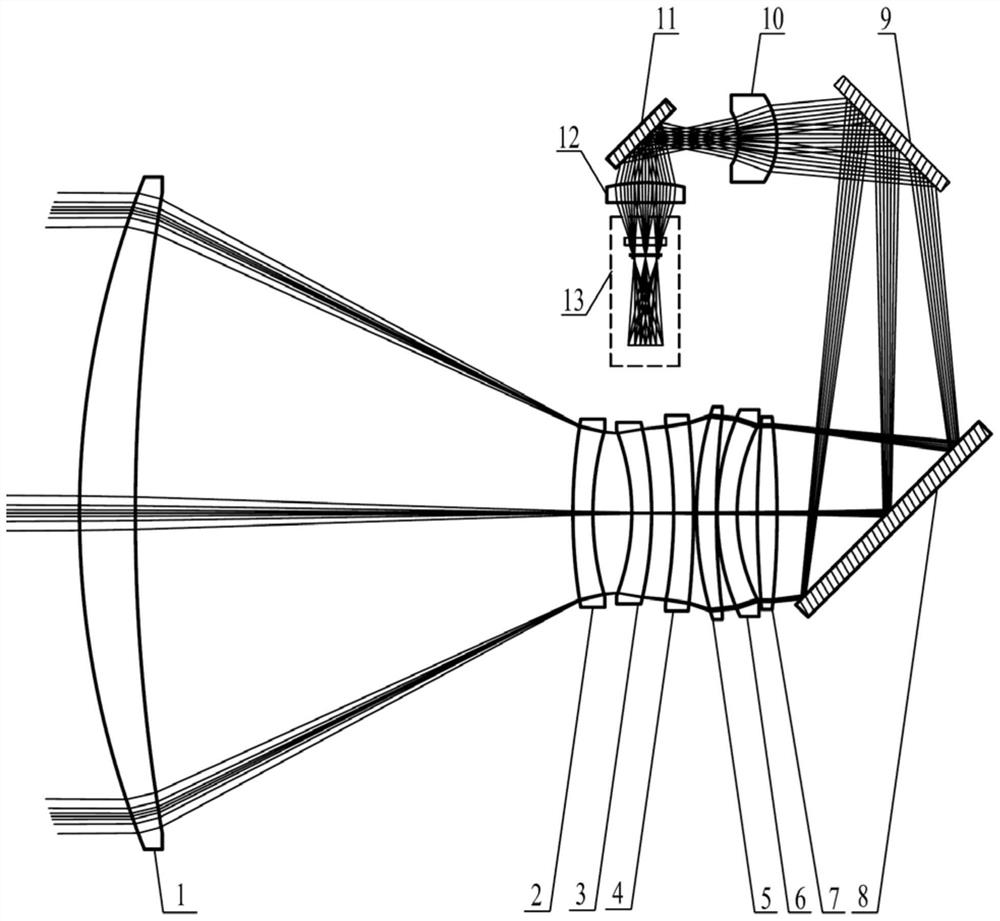

[0083] Specific technical indicators:

[0084] Waveband: 3.7μm~4.8μm; relative aperture: 1:4; focal length: 55mm~550mm; suitable for 640×512 medium-wave cooled detector with pixel size of 15μm; overall system size: 208mm×176mm×155mm (length ×width×height);

[0085] Table 1 lists the detailed data of the embodiment according to the optical system of the present invention when the focal length is 55mm~550mm, and it comprises the surface type, curvature radius, thickness, aperture, material of each lens; Wherein, the curvature radius of lens, thickness, aperture The unit is mm;

[0086]

[0087]

[0088]

[0089] Table 1

[0090] Table 2 lists the aspheric coefficients of the light incident side surface of the first meniscus negative lens 2 according to the present invention;

[0091]

[0092] Table 2

[0093] Table 3 lists the aspheric coefficient of the light incident side surface of the second meniscus positive lens 5 according to the present invention;

[009...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com