Active and passive hybrid type artificial limb knee joint

A hybrid, active and passive technology, used in prostheses, medical science, artificial legs, etc., can solve problems such as asymmetric gait, unnatural walking, and increased energy consumption, and achieve easy torque application, easy maintenance, Accurate transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

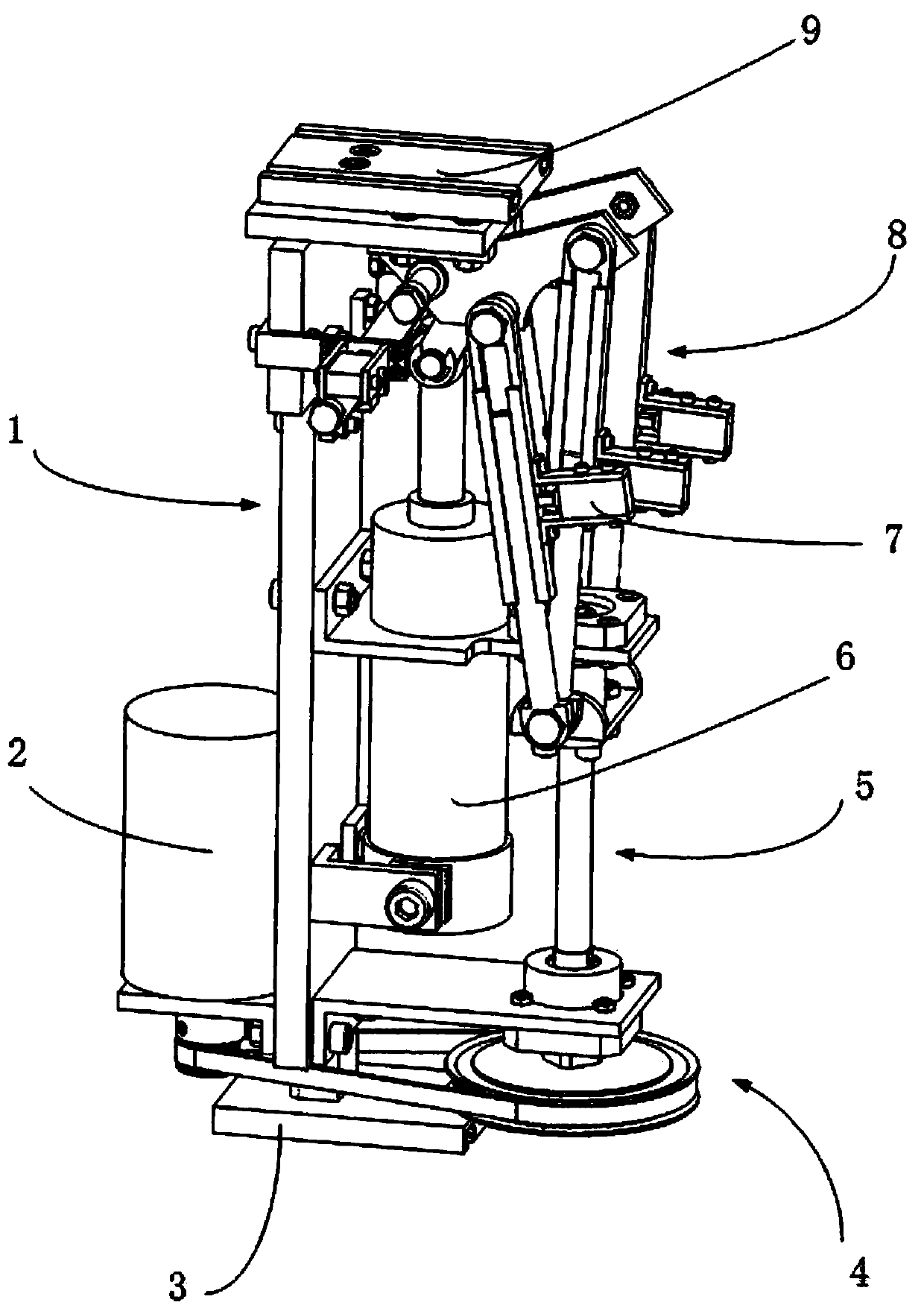

[0024] see figure 1 As shown, an active-passive hybrid prosthetic knee joint is characterized in that it includes: a support and fixation assembly 1, a motor 2, a prosthetic calf fixture 3, a synchronous pulley assembly 4, a lead screw assembly 5, a damping cylinder 6, six automatic Holding type electromagnet 7, connecting rod assembly 8 and receiving cavity fixture 9 on knee.

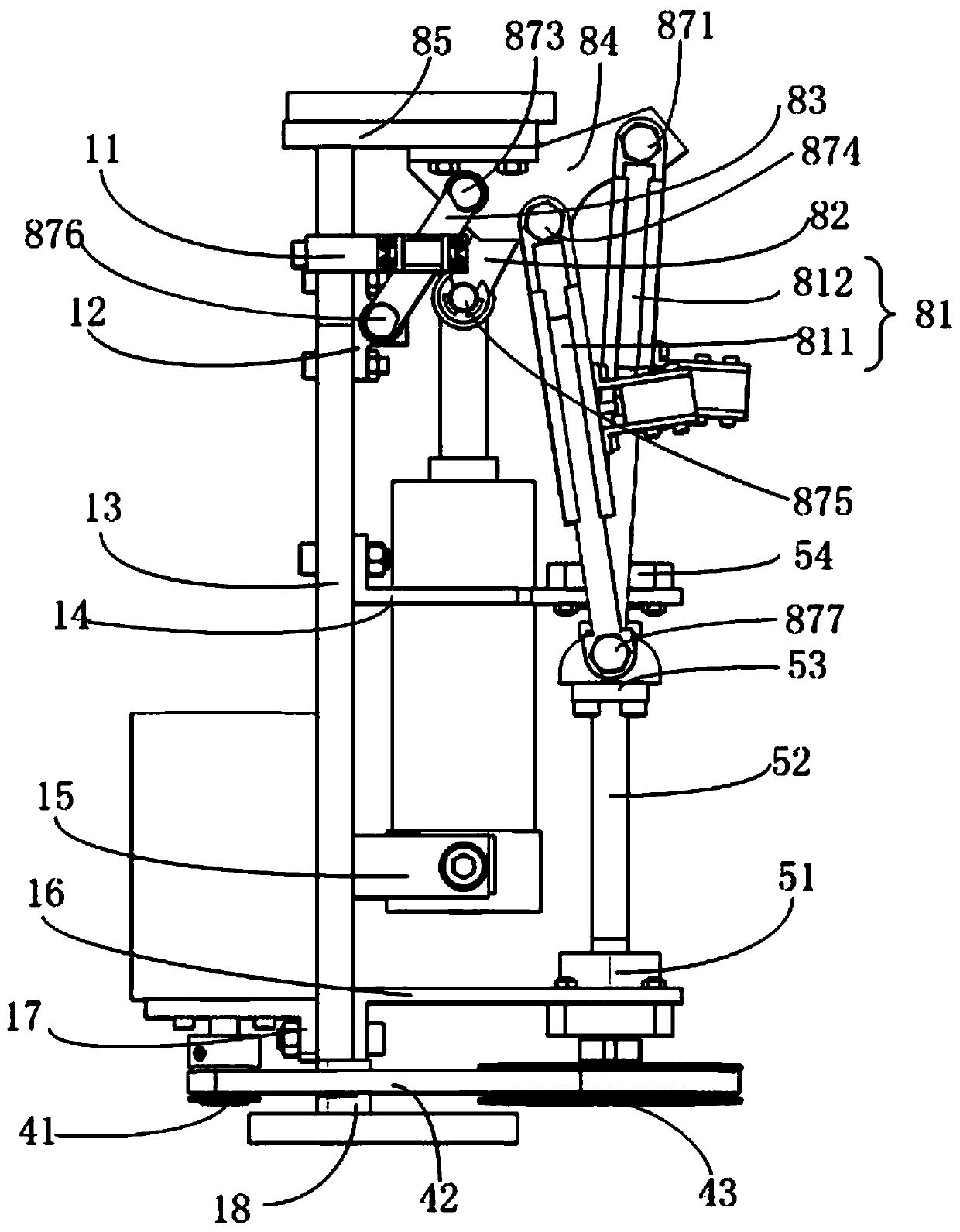

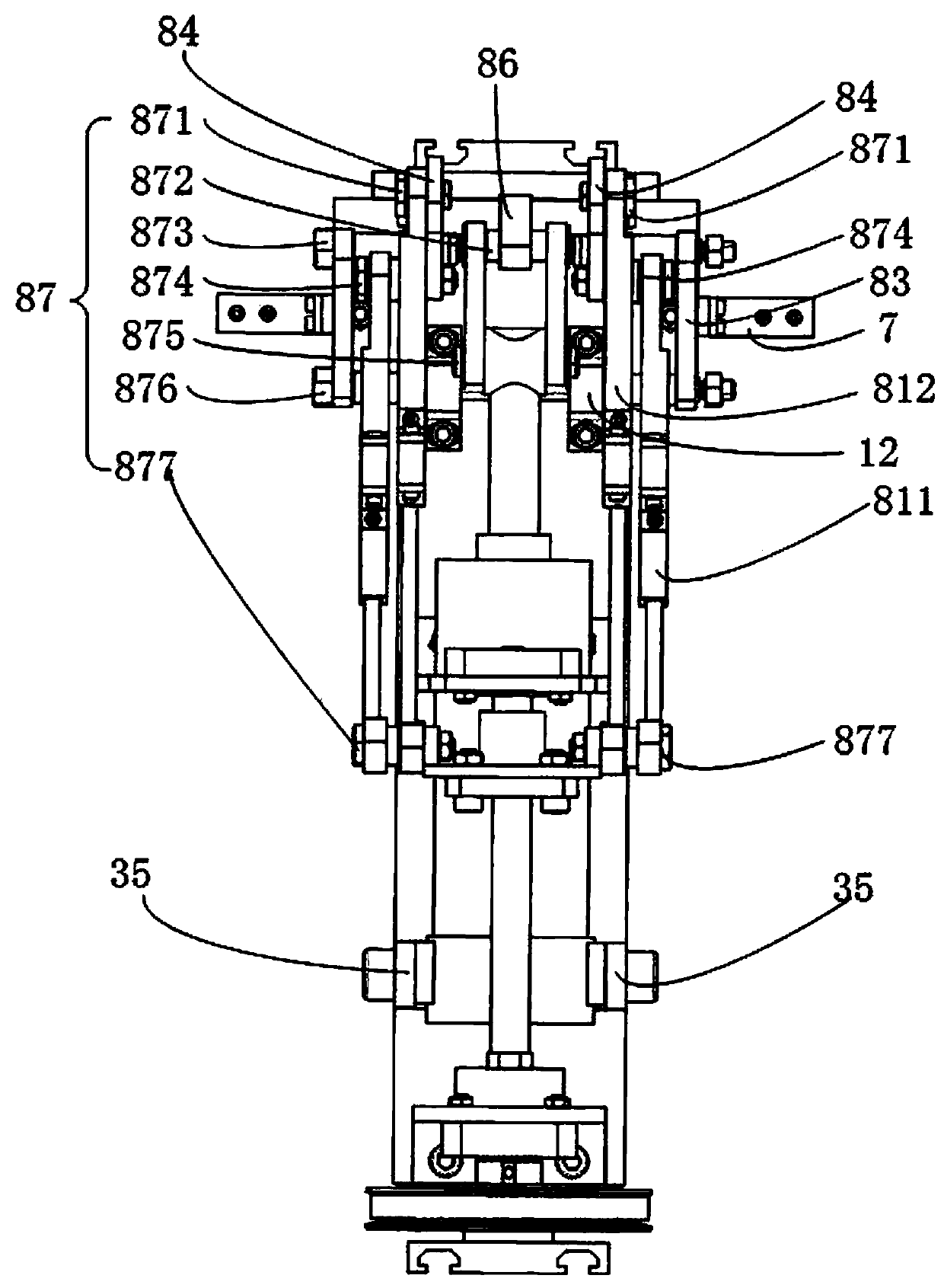

[0025] see figure 2 with image 3 As shown, the support and fixing assembly 1 includes two electromagnet fixing parts 11, two shaft seats 12, a support seat 13, a first lead screw support seat 14, two damping cylinder fixing seats 15, a second lead screw support Seat 16, motor seat 17 and shank seat 18; Electromagnet fixture 11 is L-shaped structure and is fixedly connected on support seat 13, and self-holding type electromagnet 7 is fixed on the electromagnet fixture 11, and two shaft seats 12 are The T-shaped structure is fixed on the support base 13 in parallel, the first screw support base 14 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com