Reverse flow inclined tube sedimentation tank

A technology of inclined tube sedimentation tank and sedimentation tank, which is used in sedimentation separation, flocculation/sedimentation water/sewage treatment, sedimentation tank, etc., can solve the problems of sludge discharge effect, sludge splash and other problems that affect the efficiency of sludge discharge. To achieve the effect of improving efficiency and effect, and ensuring the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

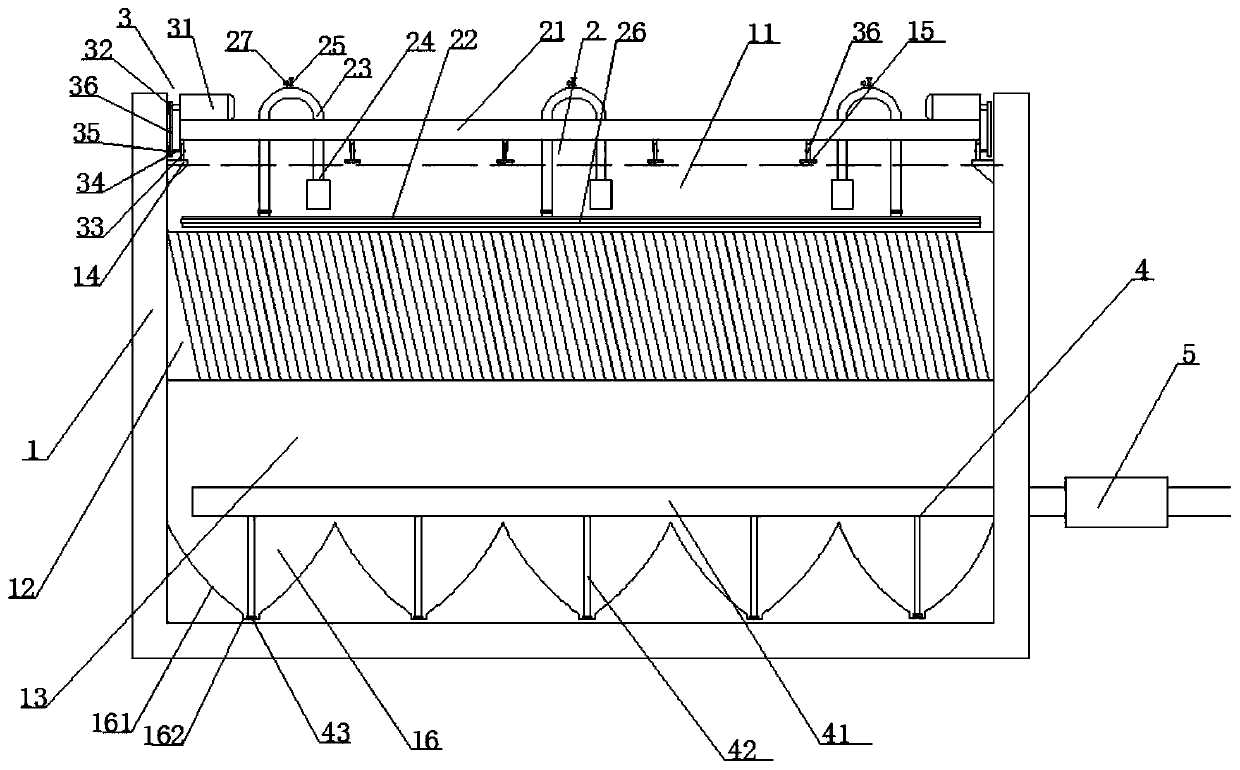

[0025] A reverse flow inclined tube sedimentation tank, comprising a sedimentation tank body 1, the sedimentation tank body 1 is sequentially provided with a mud sedimentation area 13, an inclined tube sedimentation area 12, and a water collection area 11 from bottom to top, and is characterized in that: The water collection area 11 is provided with a flushing device 2, and the bottom of the sedimentation area 13 has a plurality of sedimentation pits 16 in a rectangular array, and the edges of two adjacent sedimentation pits 16 are connected, and the sedimentation pits 16 include downward The arc-shaped ramp 161 and the downwardly recessed mud collection area 162 arranged at the bottom of the arc-shaped ramp 161, the slope of the arc-shaped ramp 161 gradually becomes smaller along the direction close to the mud collection area 162, and the mud pit 16 The top is provided with a mud discharge pipe 4, and the mud discharge pipe 4 includes a plurality of sets of mud discharge main ...

Embodiment 2

[0027] On the basis of Example 1, the flushing device 2 includes a support frame 21 whose length is the same as the width of the sedimentation tank body 1, and a cleaning main pipe 22 is arranged below the support frame 21, and the cleaning main pipe 22 is arranged along the cleaning main pipe. The length direction of 22 is provided with multiple sets of inverted U-shaped flushing pipes 23, one end of the U-shaped flushing pipes 23 is provided with a small submersible pump 24, and the middle section of the U-shaped flushing pipes 23 is provided with a manual ball valve 25 for adjusting pressure , the other end of the U-shaped flushing pipe 23 communicates with the cleaning main pipe 22, and the two sides of the cleaning main pipe 22 are provided with cleaning branch pipes 26. A low-pressure cleaning nozzle is provided, and the supporting frame 21 is provided with a moving mechanism 3 for moving the flushing device 2 back and forth along the length direction of the sedimentation...

Embodiment 3

[0029]On the basis of Embodiment 1 or 2, the moving mechanism 3 includes a variable frequency deceleration motor 31 arranged at both ends of the upper end surface of the support frame 21, and the output shaft of the variable frequency deceleration motor 31 is provided with a sprocket 1 32, and the support The two ends of the lower end surface of the frame 21 are provided with driving wheels 33, and the left and right side walls of the sedimentation tank body 1 above the water collection area 11 are provided with main slide rails 14 along the length direction of the sedimentation tank body 1. Drive wheel 33 can freely roll along the length direction of main slide rail 14 on main slide rail 14, and described drive wheel 33 center is provided with rotating shaft 34, and described rotating shaft 34 outer ends are fixedly connected with sprocket wheel 2 35, and described sprocket wheel Link by chain 36 between one 32 and sprocket two 35.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com