Method for filling gaps between steel plates

A filling method and steel plate technology, applied in the direction of welding medium, arc welding equipment, welding/cutting medium/material, etc., to achieve the effect of increasing strength, improving toughness, and reducing cold crack sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

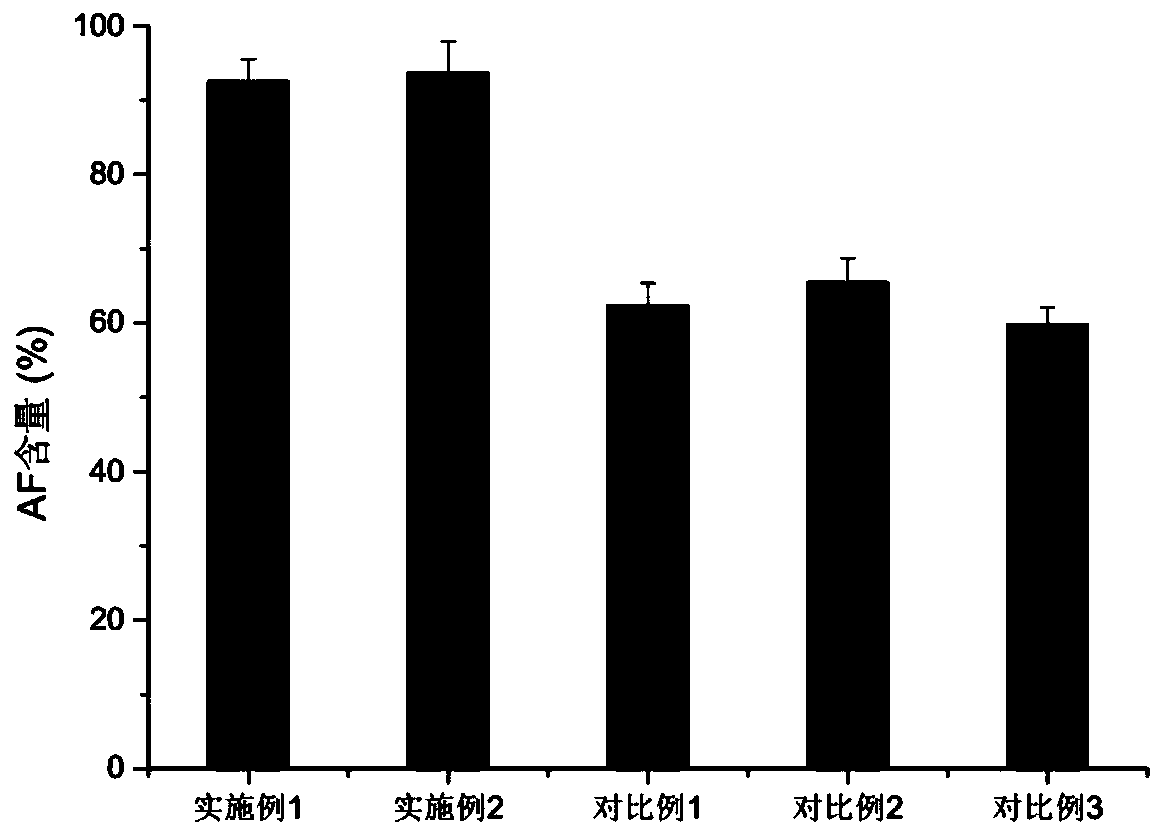

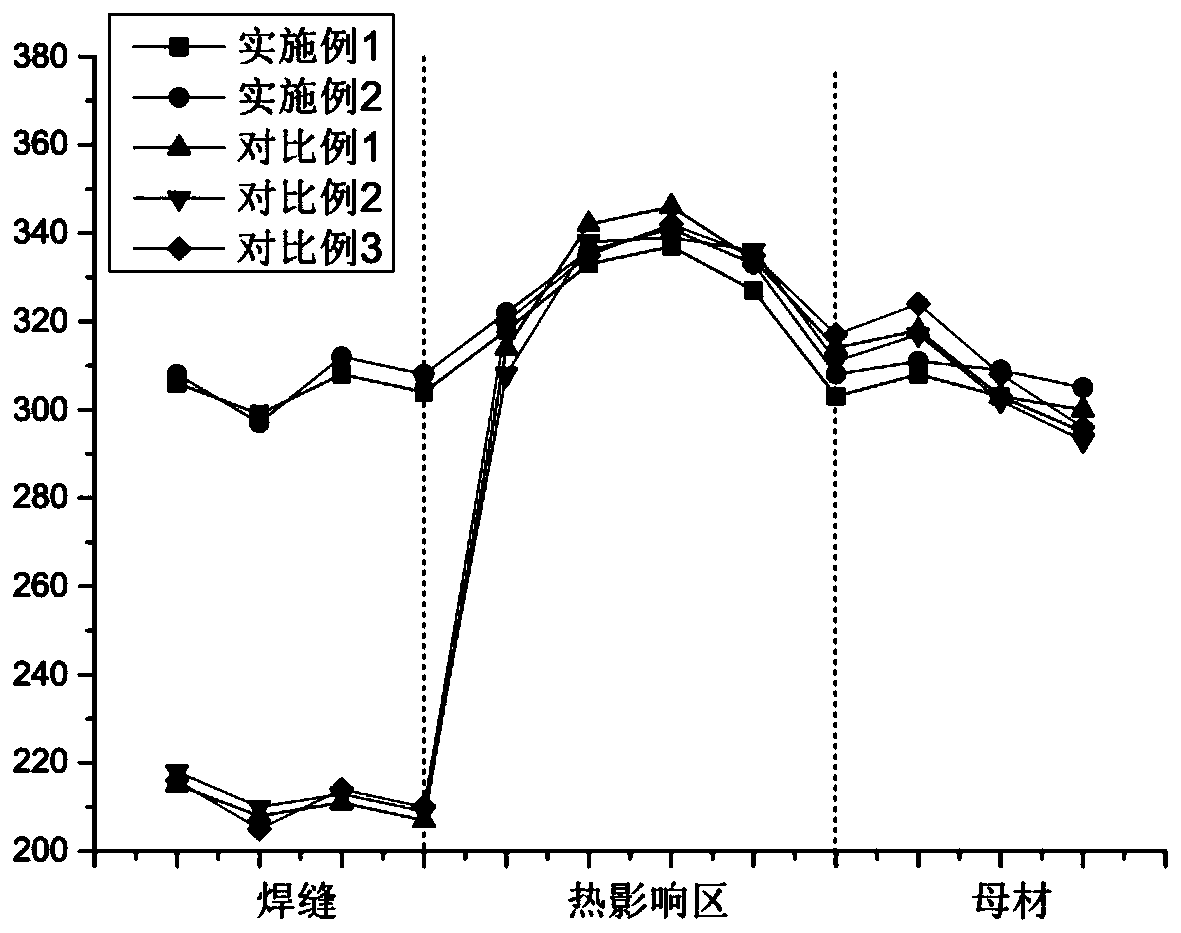

Embodiment 1

[0046] A method for filling gaps between steel plates, comprising the following steps:

[0047] S1: Clean the gap between the steel plates to be filled. The steel plates are low-alloy high-strength steels. The composition is shown in Table 1, and the mechanical properties are shown in Table 2;

[0048] S2: Preheating the gap filling area at 70 °C;

[0049] S3: Use welding filler to weld and fill the gaps between the steel plates to form joints, and perform three-layer welding on the joints, each layer is welded three times, and the weld seam must be ground before the next layer is welded;

[0050] In this embodiment, the welding adopts semi-automatic mixed gas shielded welding, and the welding shielding gases are He, Ar and CO 2 Mixed gas shielding, He, Ar and CO 2 The volume ratio is 1:1.2:0.15, and the polarity of the power supply is reversed; the welding seam forming method is single-sided welding, double-sided forming, and the welding process parameters are shown in Tabl...

Embodiment 2

[0059] A method for filling gaps between steel plates, comprising the following steps:

[0060] S1: Clean the gap between the steel plates to be filled, the steel plate is the low-alloy high-strength steel used in Example 1;

[0061] S2: Preheating the gap filling area at 85 °C;

[0062] S3: Use welding filler to weld and fill the gap between the steel plates to form a joint, and perform 4-layer welding on the joint, with 4 welds for each layer, and the weld seam must be ground before the next welding;

[0063] In this embodiment, the welding adopts semi-automatic mixed gas shielded welding, and the welding shielding gases are He, Ar and CO 2 Mixed gas shielding, He, Ar and CO 2 The volume ratio is 1:1.2:0.15, and the polarity of the power supply is reversed; the welding seam forming method is single-sided welding, double-sided forming, and the welding process parameters are shown in Table 4.

[0064] The welding filler used in this embodiment includes 30% by weight of iron...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com