Printing method of quantum dot ink

A quantum dot and ink technology, applied in the field of quantum dot ink printing, can solve the problems of poor definition and uniformity of printing patterns, and achieve the effect of simplifying the solvent system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

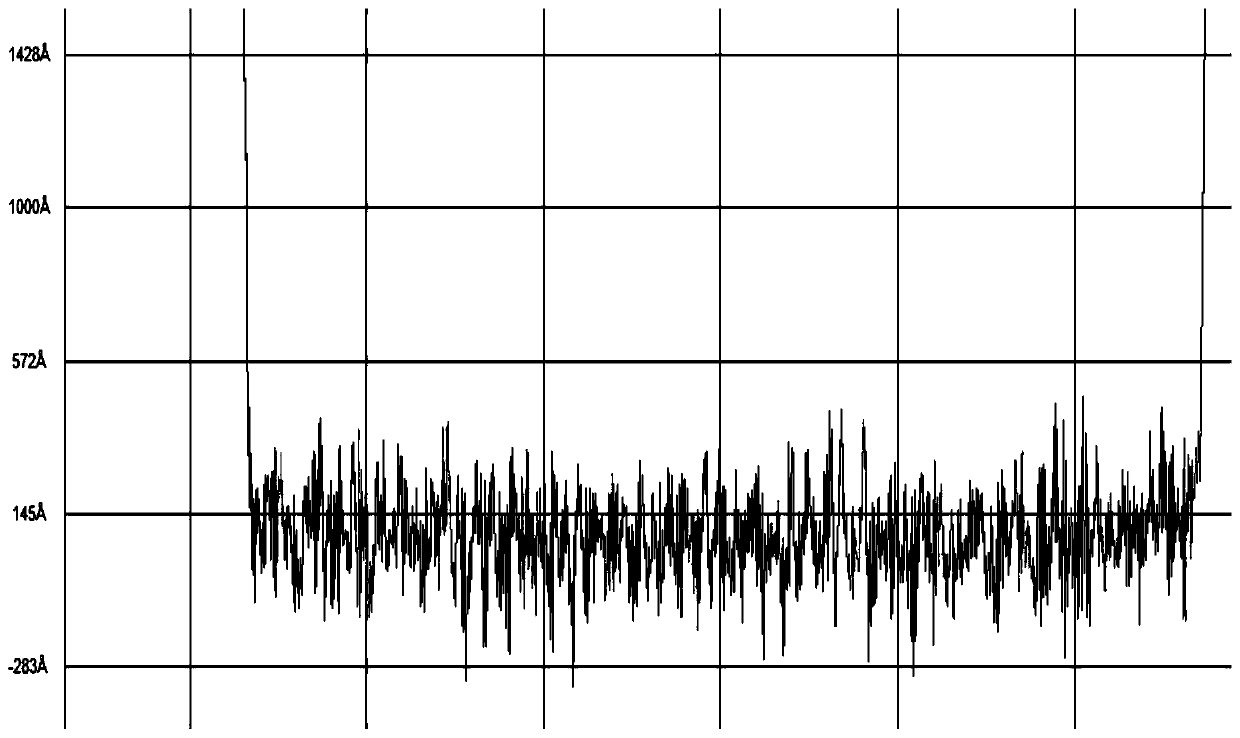

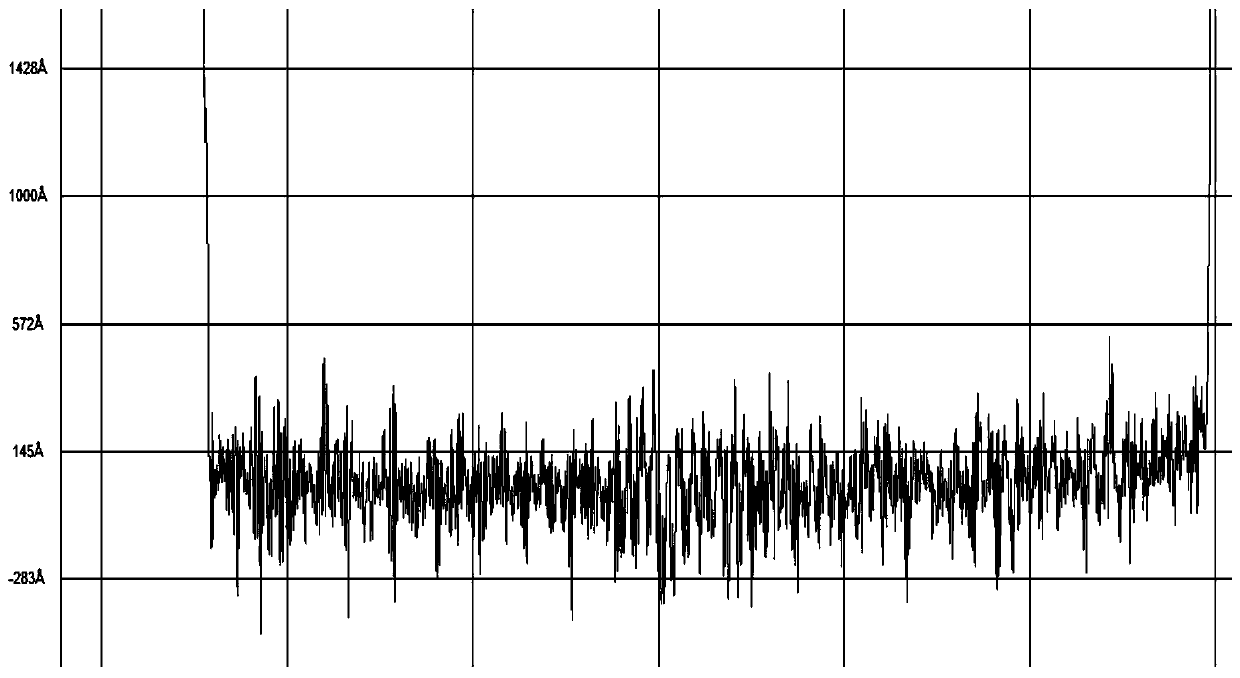

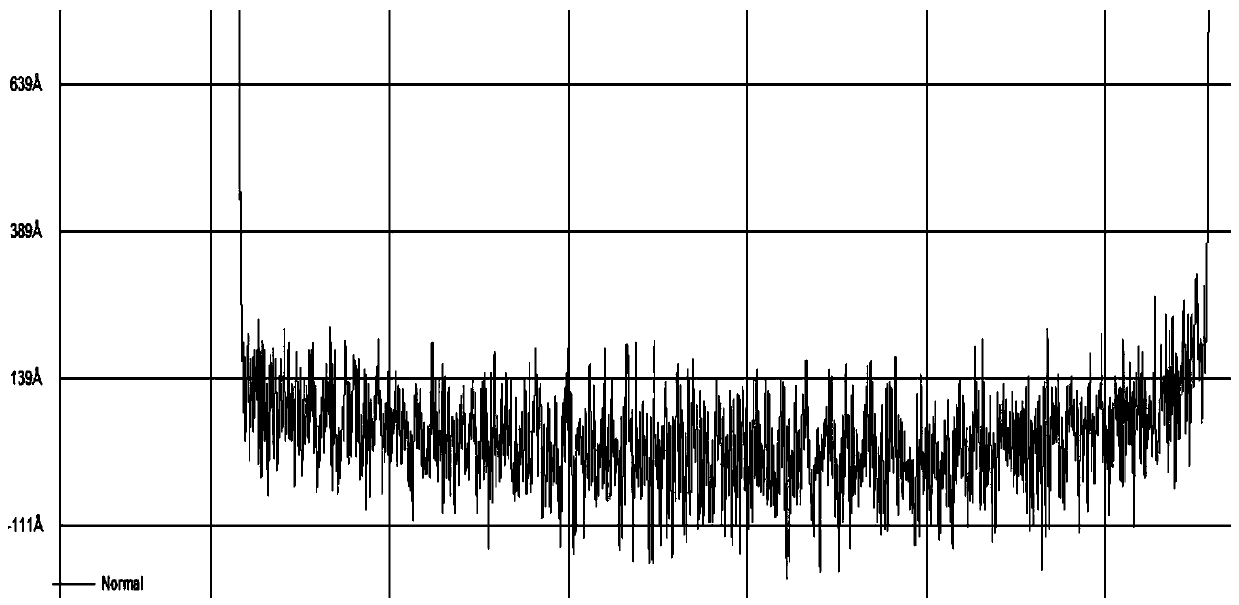

Image

Examples

preparation example Construction

[0037] In a preferred embodiment, the preparation method of the above-mentioned quantum dot ink includes: in the presence of a weakly alkaline solvent, subjecting the secondary quantum dot solution and the surfactant to a surface modification reaction and separating and purifying to obtain the first The first quantum dot and the second solvent form a dispersion liquid to obtain the quantum dot ink.

[0038] The surface modification reaction of the secondary quantum dot solution and the surfactant is carried out, so that the solubility of the secondary quantum dot solution is changed into primary quantum dots. Adding a weakly basic solvent to the above surface modification reaction is beneficial to further improving the reaction speed of the surface modification reaction and shortening the process time. At the same time, the quantum dot ink prepared by the above method has high stability, and the preparation process is relatively simple.

[0039] In a preferred embodiment, the...

Embodiment 1

[0049] Prepare water-soluble quantum dot ink:

[0050] Mix and stir 10mL oil-soluble quantum dot solution (solvent is toluene, 80mg / mL) and ethanol solution of 40mL surfactant phosphatidylethanolamine (200mg / mL) to obtain a mixed solution. The time is 30min, and the stirring temperature is 30°C. Then, 60 mL of ammonia water (concentration of the original ammonia water was 28 wt%, obtained by diluting 15 times with ethanol) was added to the above mixed solution, and stirring was continued for 60 min at a stirring temperature of 30°C. After the reaction was complete, the supernatant was removed by centrifugation to obtain a precipitate. After shaking and dispersing the obtained precipitate with hexane and methyl ethyl ketone (1:1), remove the supernatant again, keep the precipitate, repeat 1 to 3 times, and finally use propylene glycol methyl ether and ethylene glycol (volume 6:4) Mix and dissolve, and prepare a dispersed precipitate at a concentration of 80 mg / mL to obtain a w...

Embodiment 2

[0058] Prepare water-soluble quantum dot ink with embodiment 1.

[0059] Prepare the breaker solution: Dissolve the selected breaker in the same solvent as the ink (propylene glycol methyl ether: ethylene glycol (6:4) mixed solution) to prepare a 200mg / mL solution. The functional component of the breaking agent of this embodiment is methyl trioctyl ammonium chloride.

[0060] The preparation method of quantum dot luminescent layer is as follows:

[0061] S1 and S3 are the same as embodiment 1. S2, print 20pL of destroyer in each pixel pit, so that the weight ratio of water-soluble quantum dots to destroyer is 1:1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com