A kind of rosin-based carbon dot material and its preparation method and application

A technology based on rosin and carbon dots, applied in the field of carbon dot materials, can solve the problems of complex preparation method, low CDs yield, long time-consuming purification and separation, etc., and achieves a simple and easy-to-operate preparation method, abundant raw materials, and environmentally friendly operation steps. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] The invention provides a kind of preparation method of rosin-based carbon dot material, comprising the following steps:

[0029] The rosin-like resin acid is mixed with water for hydrothermal reaction to obtain the rosin-based carbon dot material.

[0030] In the present invention, unless otherwise specified, the required preparation materials are commercially available products well known to those skilled in the art.

[0031] In the present invention, the abietic resin acid is preferably a resin acid having a tricyclic phenanthrene skeleton structure, more preferably one or more of abietic acid type resin acids, pimaric acid type resin acids and isopimaric acid type resin acids. kind.

[0032] In the present invention, the structural formula of described abietic acid type resin acid is preferably:

[0033]

[0034]

[0035] In the present invention, the structural formula of described pimaric acid type resin acid is as follows:

[0036]

[0037] In the pres...

Embodiment 1

[0047] Put 0.7g of hydrogenated rosin (hydrogenated abietic acid) into a 100mL hydrothermal synthesis reactor, then pour 70mL of deionized water into the hydrothermal synthesis reactor, mix well, perform a hydrothermal reaction at 180°C for 12h, and cool naturally to After room temperature, a water-based microporous filter membrane with a pore size of 0.22 μm was used for suction filtration to separate the filtrate, and the filtrate was freeze-dried to obtain a rosin-based CDs solid, that is, a rosin-based carbon dot material.

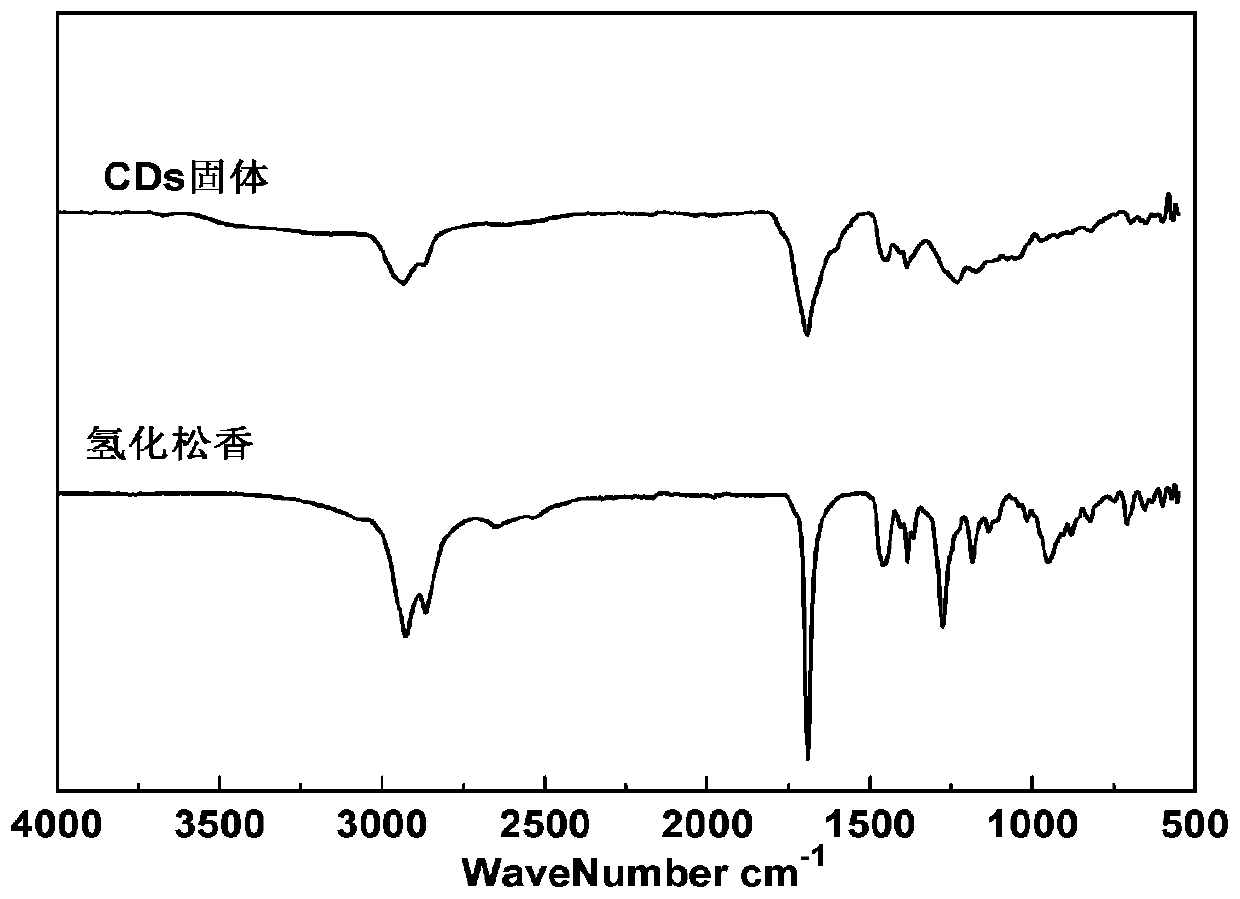

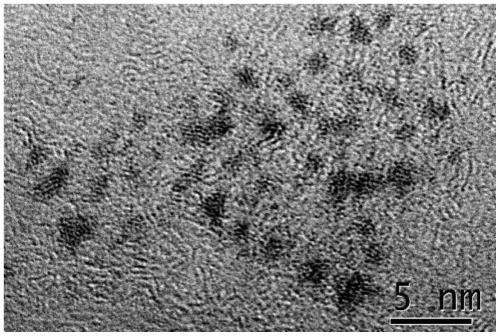

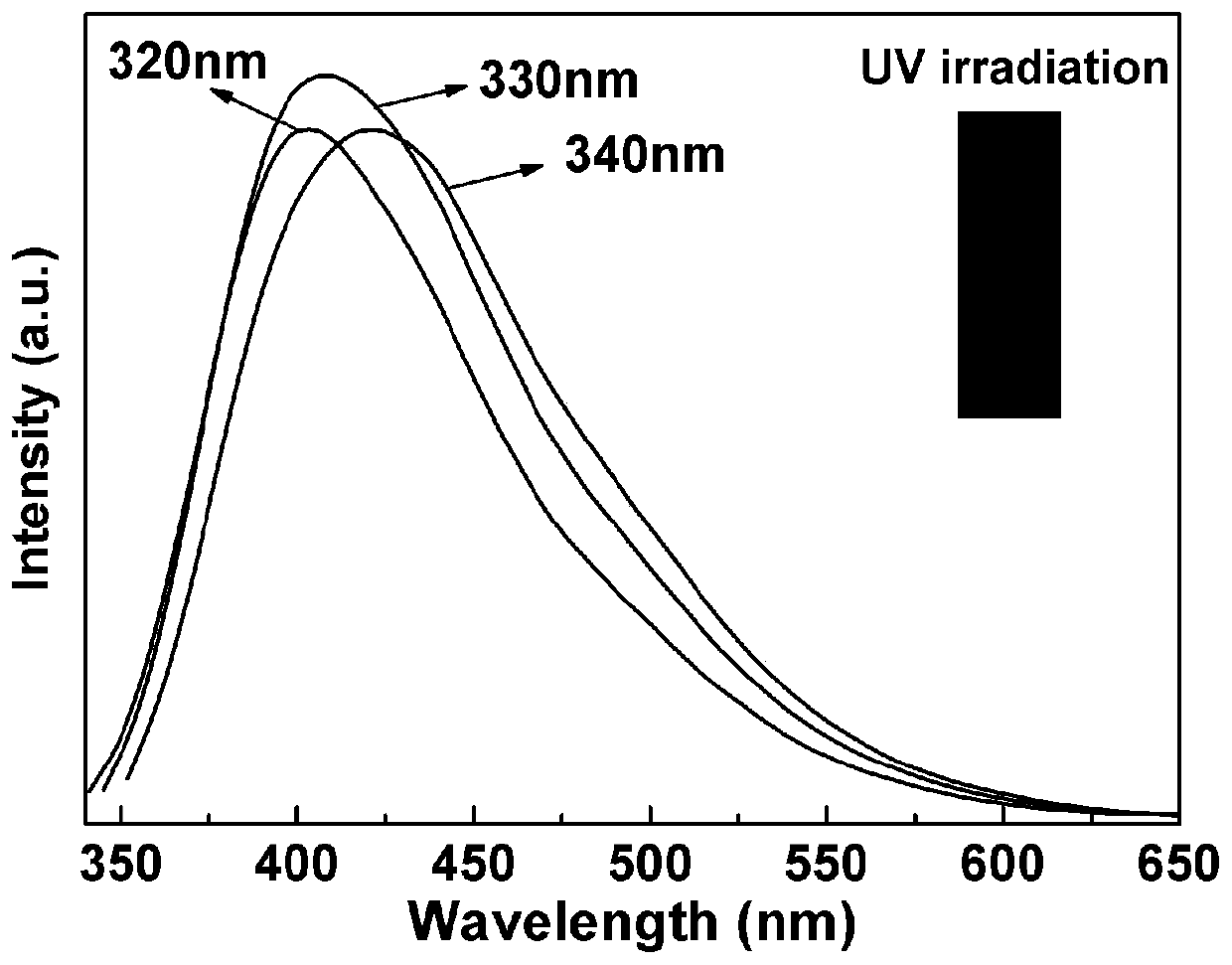

[0048] figure 1For the infrared spectrogram of the CDs solid prepared in Example 1 and the hydrogenated rosin raw material, it can be seen from the figure analysis that the functional group structure of CDs is basically consistent with the raw material, indicating that the carbon core surface may retain the basic structural unit of the tricyclic phenanthrene resin acid of the raw material; Moreover, it is precisely because the basic functional groups o...

Embodiment 2

[0056] Put 0.1g of hydrogenated rosin (hydroabietic acid) into a 100mL hydrothermal synthesis reaction kettle, then pour 70mL of deionized water into the hydrothermal synthesis reaction kettle, mix well, perform a hydrothermal reaction at 240°C for 5h, and cool naturally to After room temperature, a water-based microporous filter membrane with a pore size of 0.22 μm was used for suction filtration to separate the filtrate, and the filtrate was freeze-dried to obtain a solid rosin-based CDs, that is, a rosin-based carbon dot material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com