A kind of steelmaking production method of 600mpa grade peritectic high alumina trip steel

A production method and peritectic technology, applied in the field of metallurgy, can solve the problems of strong crack sensitivity, large fluctuation of the liquid level of the continuous casting mold, internal segregation of the slab and difficulty in surface cracks, etc. The effect of stable production process control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

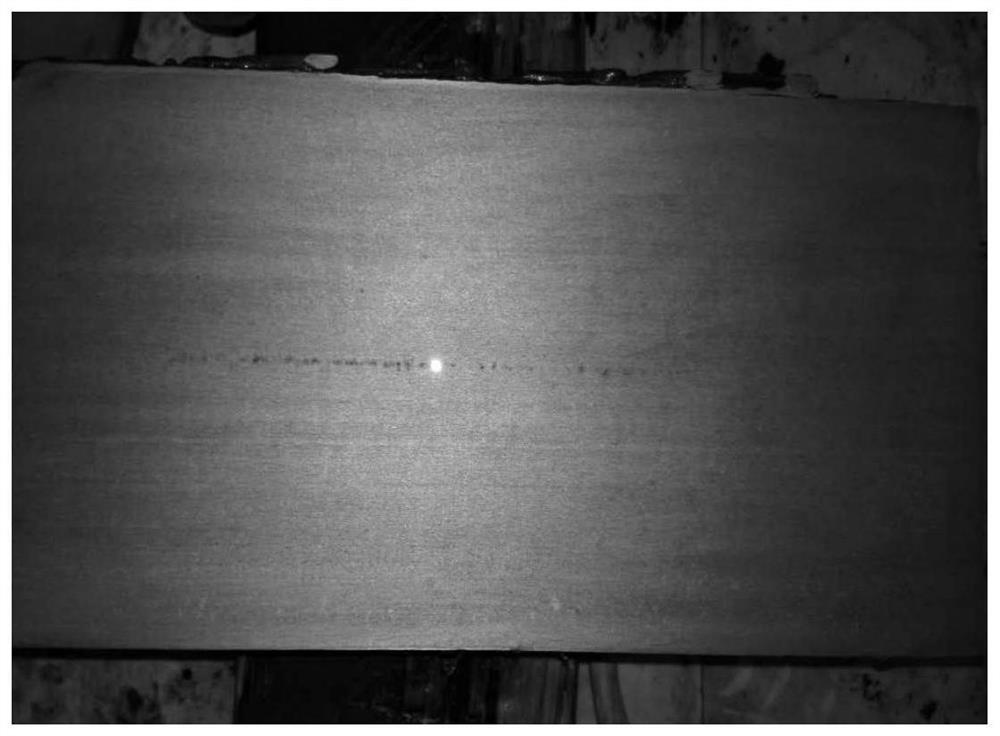

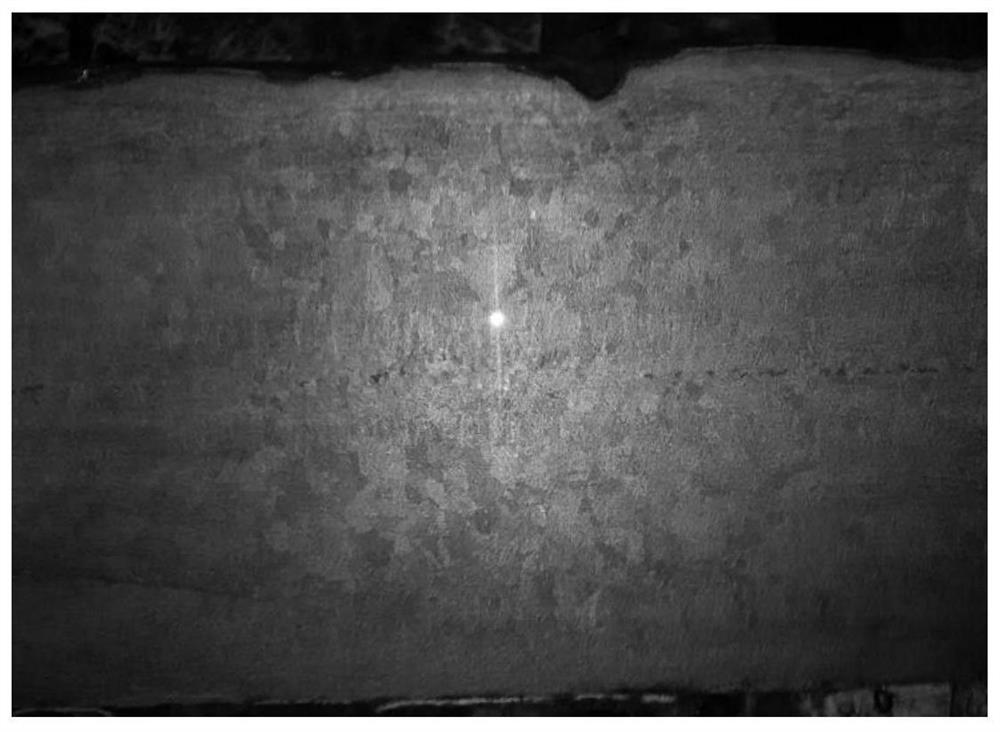

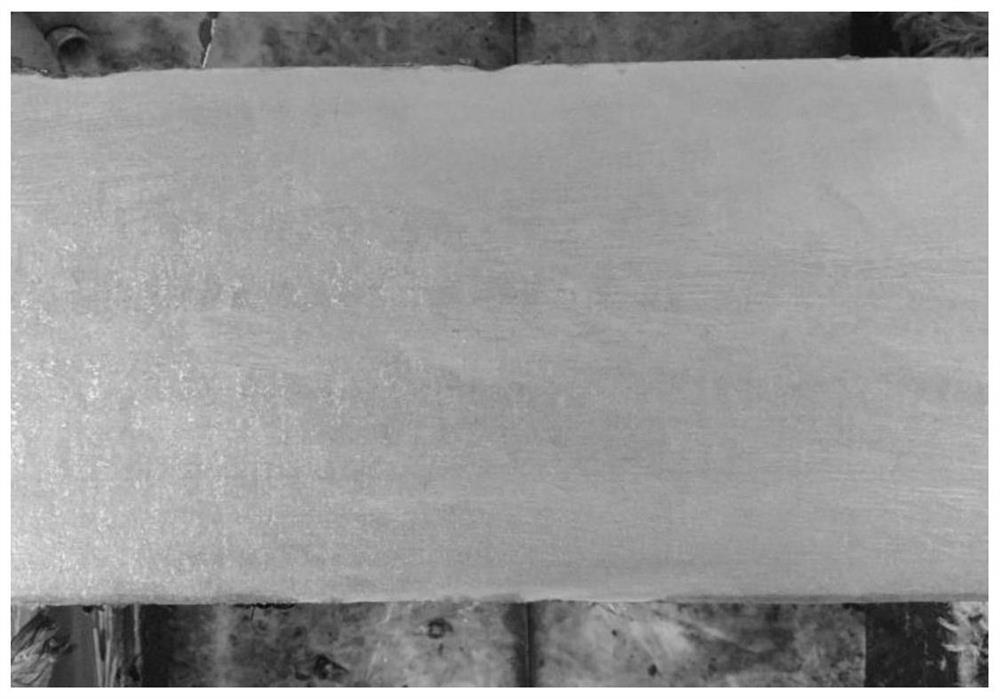

Image

Examples

Embodiment 1

[0033] The steelmaking production method of 600MPa peritectic high-alumina TRIP steel in this embodiment includes molten iron desulfurization, converter smelting, LF refining, RH treatment, and continuous casting of medium slabs. The specific process steps are as follows:

[0034] (1) Desulfurization process of molten iron: After spraying magnesium powder and lime on the ladle for desulfurization, the slag is removed, and the molten iron is desulfurized to S: 0.010%;

[0035] (2) Converter smelting process: the temperature of molten iron entering the furnace is 1280°C, C: 4.1%, S: 0.010%, P: 0.110%; S: 0.009%, P: 0.009%, the end point temperature is 1670°C, no steel sample is taken after the first carbon drawing of the converter, the angle of the converter body is restored to 0°, the bottom blowing and strong stirring is 120s, and the bottom blowing intensity is 0.18m 3 / t*min, the steel is tapped directly after bottom blowing and strong stirring, the tapping time is 3min, 2.5...

Embodiment 2

[0041] The steelmaking production method of 600MPa peritectic high-alumina TRIP steel in this embodiment includes molten iron desulfurization, converter smelting, LF refining, RH treatment, and continuous casting of medium slabs. The specific process steps are as follows:

[0042] (1) Desulfurization process of molten iron: After spraying magnesium powder and lime on the ladle for desulfurization, the slag is removed, and the molten iron is desulfurized to S: 0.005%;

[0043] (2) Converter smelting process: The temperature of molten iron entering the furnace is 1350°C, C: 3.5%, S: 0.005%, P: 0.150%; the basicity of the final slag of converter smelting is 4.5, and C: 0.035%, S: 0.005%, P: 0.010%, the end point temperature is 1690°C, no steel sample is taken after the first carbon drawing of the converter, the angle of the converter body is restored to 0°, the bottom blowing and strong stirring is 125s, and the bottom blowing intensity is 0.15m 3 / t*min, the steel is tapped dire...

Embodiment 3

[0049] The steelmaking production method of 600MPa peritectic high-alumina TRIP steel in this embodiment includes molten iron desulfurization, converter smelting, LF refining, RH treatment, and continuous casting of medium slabs. The specific process steps are as follows:

[0050] (1) Desulfurization process of molten iron: After spraying magnesium powder and lime on the ladle for desulfurization, the slag is removed, and the molten iron is desulfurized to S: 0.008%;

[0051] (2) Converter smelting process: the temperature of the molten iron entering the furnace is 1200°C, the molten iron entering the furnace is C: 4.5%, S: 0.008%, P: 0.150%; S: 0.008%, P: 0.008%, the end point temperature is 1680°C, no steel sample is taken after the converter is pulled carbon once, the angle of the converter body is restored to 0°, the bottom blowing and strong stirring is 130s, and the bottom blowing intensity is 0.16m 3 / t*min, the steel is tapped directly after bottom blowing and strong s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com