Three-dimensional graphene composite material with core-shell structure for capacitive desalination electrode and preparation method thereof

A core-shell structure, composite material technology, applied in separation methods, chemical instruments and methods, water/sewage treatment equipment, etc., can solve the problems of complex preparation process, unenvironmental nitrogen source, etc., achieve high surface area, inhibit stacking, good The effect of the application foreground

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

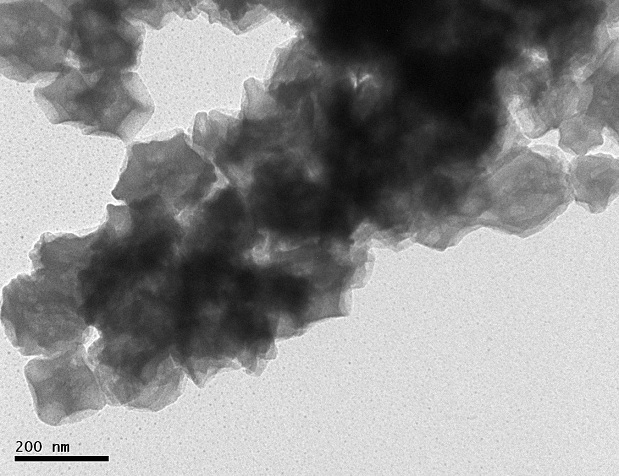

Image

Examples

Embodiment 1

[0021] Example 1: Dissolve zinc nitrate hexahydrate and 2-methylimidazole with a molar ratio of 1:4 in 200 ml of methanol solution, wherein the concentration of zinc nitrate is 1.5 wt%, and the stirring speed is 350rpm / min under vigorous stirring for 12 hours, centrifuge, wash with methanol solution 2 to 3 times, and dry to obtain the metal-organic framework ZIF-8; disperse 0.2 g of the obtained metal-organic framework ZIF-8 in an aqueous solution of graphite oxide with a mass concentration of 0.1 wt%, and place it in an 80° water bath Stir evenly until dry; place the obtained three-dimensional graphene composite with core-shell structure in a tube furnace, under the protection of nitrogen with a gas flow rate of 80 mL / min, control the heating rate at 2 °C / min, raise the temperature to 800 °C, and Heat at 800 ℃ for 3 h, after cooling to room temperature, add 2M hydrochloric acid solution and stir to remove metal oxides for 12 h, after washing and drying thoroughly, the three-di...

Embodiment 2

[0023]Example 2: Dissolve zinc nitrate hexahydrate and 2-methylimidazole in a molar ratio of 1:6 in 100 ml of methanol solution, wherein the concentration of zinc nitrate is 3 wt%, and stir vigorously at a stirring speed of 400 rpm / min After 12 hours, centrifuge, wash with methanol solution for 2-3 times, and dry to obtain the metal organic framework ZIF-8; disperse 0.4 g of the obtained metal organic framework ZIF-8 in a mass concentration of 0.2wt% graphite oxide aqueous solution, at 80 ° Stir evenly in a water bath until dry; place the obtained three-dimensional graphene composite with core-shell structure in a tube furnace, under the protection of nitrogen with a gas flow rate of 100 mL / min, control the heating rate at 3 °C / min, and raise the temperature to 800 °C. Insulate at 800 °C for 3 h, after cooling to room temperature, add 2M hydrochloric acid solution and stir to remove metal oxides for 10 h, after washing and drying thoroughly, the three-dimensional graphene compo...

Embodiment 3

[0025] Embodiment 3: Zinc nitrate hexahydrate and 2-methylimidazole with a mol ratio of 1:8 are dissolved in 300 ml of methanol solution, wherein the concentration of zinc nitrate is 1 wt%, and stirring speed is 460rpm / min under vigorous stirring for 12 hour, centrifuge, wash with methanol solution 2 to 3 times, and dry to obtain the metal organic framework ZIF-8; disperse 0.8 g of the obtained metal organic framework ZIF-8 in a graphite oxide aqueous solution with a mass concentration of 0.1 wt%, and place it in an 80° water bath Stir evenly until dry; place the obtained three-dimensional graphene composite with core-shell structure in a tube furnace, under the protection of nitrogen gas with a gas flow rate of 110mL / min, control the heating rate at 4 °C / min, raise the temperature to 800 °C, and at 800 °C ℃ for 3 h, after cooling to room temperature, add 2M sulfuric acid solution and stir to remove metal oxides for 12 h, after fully washing and drying, the three-dimensional gr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| salt rejection rate | aaaaa | aaaaa |

| salt rejection rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com