Device for preparing metal particles through continuous electrochemical deposition

A metal particle, electrodeposition technology, applied in the direction of electrolysis process, electrolysis components, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

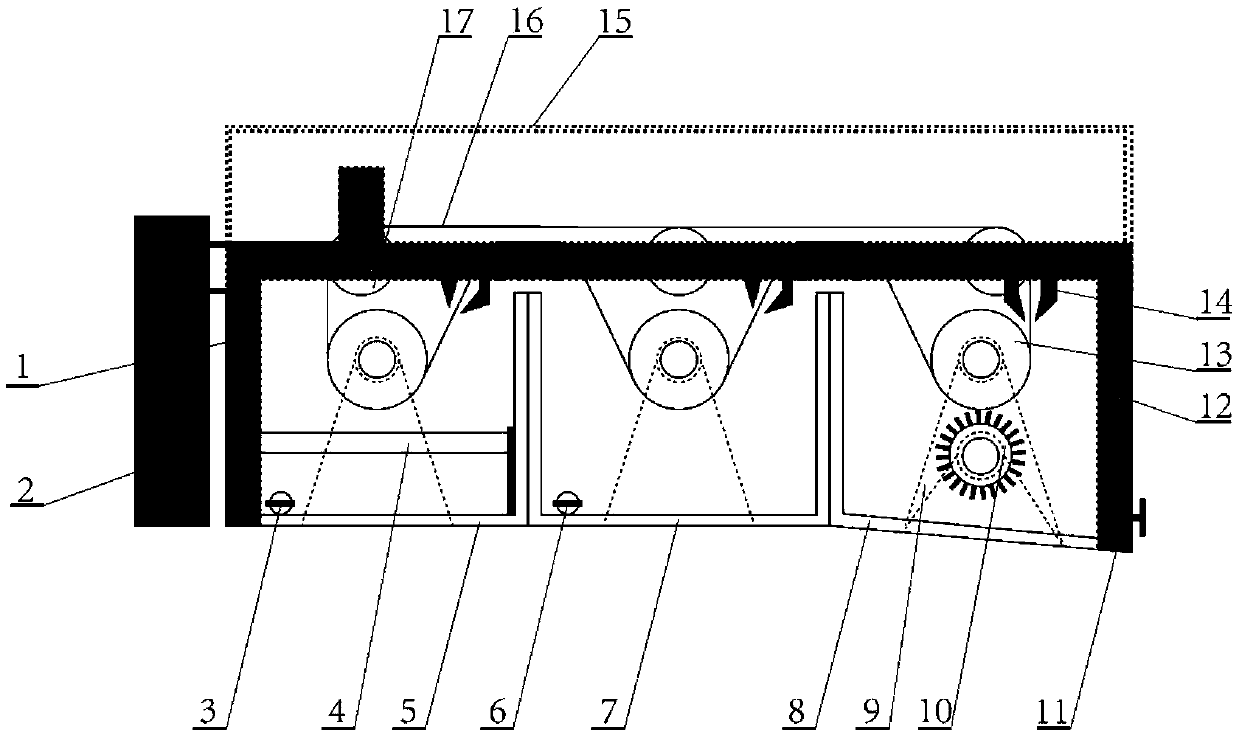

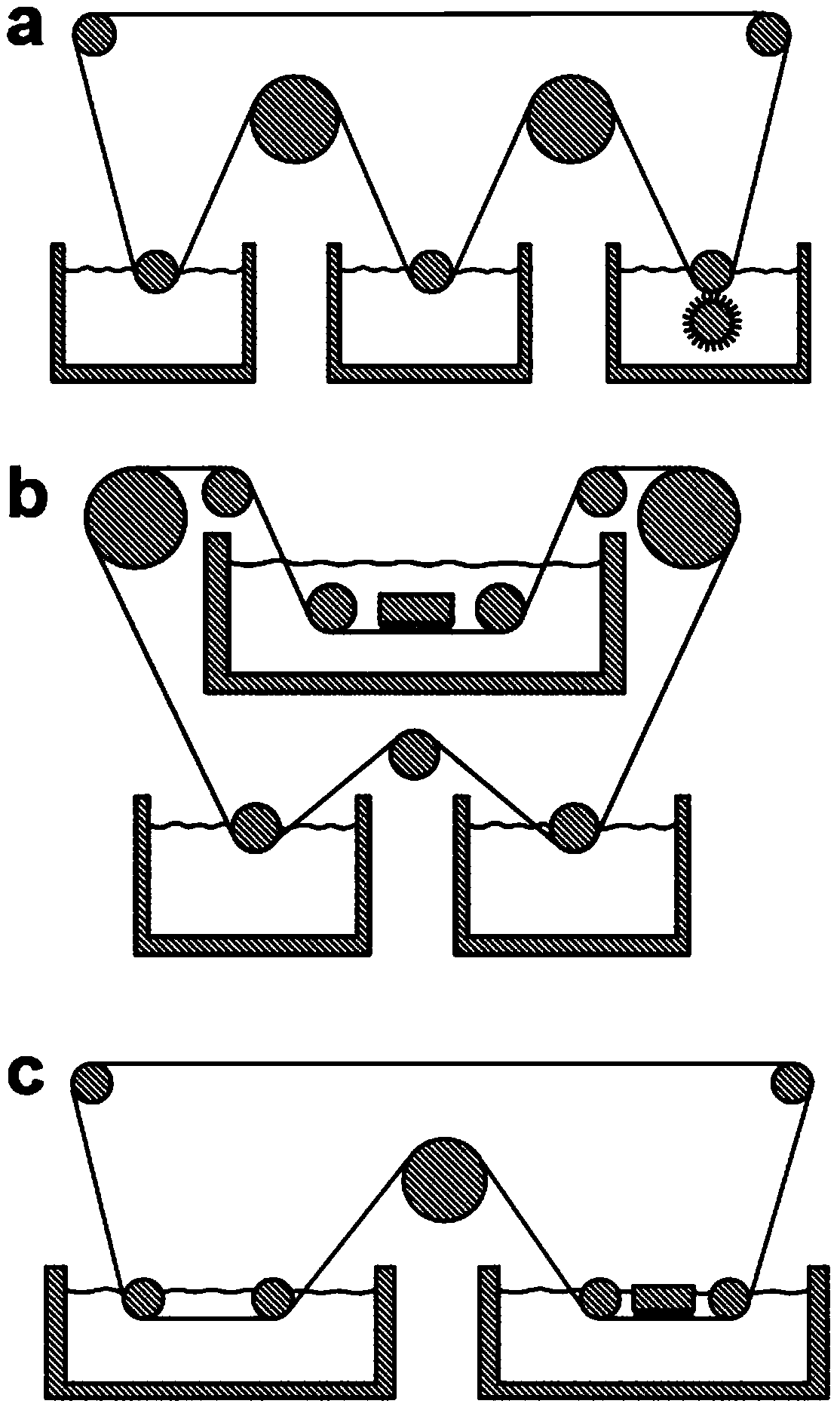

[0083] A device for preparing metal particles by continuous electrodeposition by controlling the cathode speed, the contact force between the prepared metal particles and the cathode is less than 25nN, or the shear strength is less than 1MPa, such as figure 1 As shown, the device includes:

[0084] (a) power supply (2), electrodeposition tank (5), cleaning tank (7), collection tank (8), wherein electrodeposition tank (5), cleaning tank (7), and collection tank (8) are connected in sequence, The power supply (2) adjusts the parameters of electrochemical deposition, and conducts electrodeposition in constant current or constant voltage mode. The current density range in the process of constant current mode is 0-10mA / cm 2 , the voltage range during the constant voltage mode is 0~10V;

[0085] (b) an anode (4) and a cathode (16) arranged oppositely in the electrodeposition tank (5); the anode (4) is connected to the power supply (2) through the anode lead (1) and the cathode (16)...

Embodiment 2

[0093] Prepare silver particles by electrodeposition in constant voltage mode with the device of Example 1

[0094] (1) Preparation of electrolyte, preparation of 5g / L AgNO 3 , 25g / L Na 2 S 2 o 3 ·5H 2 O, 5g / LK 2 SO 3 and 5g / L H 3 BO 3 mixed solution;

[0095] (2) Select a cathode that can move continuously, the cathode adopts a stainless steel strip, and the surface of the cathode stainless steel strip is polished;

[0096] (3) Adjust the parameters of electrochemical deposition, and carry out electrodeposition in constant voltage mode. The electrochemical workstation used is CHENHUA760, and the voltage range in the process of constant voltage mode is 0.4V;

[0097] (4) The cathode stainless steel strip passes through the electrodeposition tank, cleaning tank, and collection tank continuously and in sequence, and then directly returns to the electrodeposition tank, and the cathode forms a continuous and circular movement;

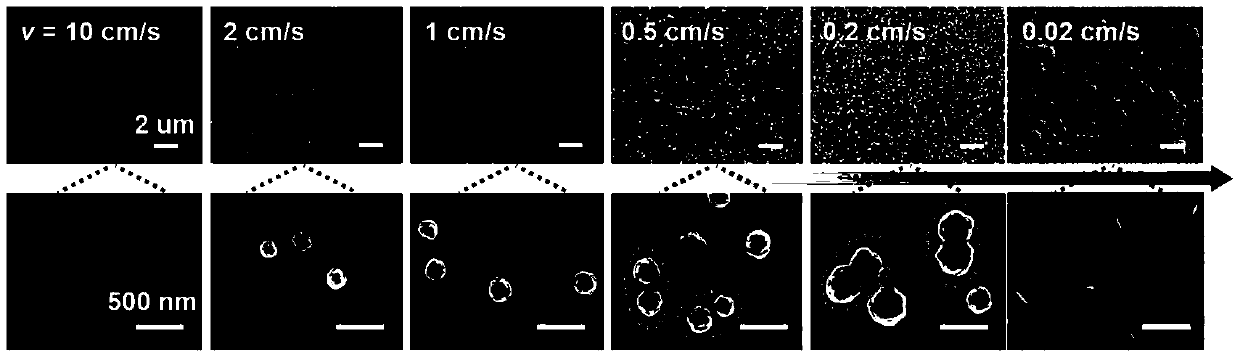

[0098] (5) In the electrodeposition tank, ...

Embodiment 3

[0105] Silver particles were prepared by electrodeposition in constant current mode with the device of Example 1

[0106] (1) Preparation of electrolyte, preparation of 5g / L AgNO 3 , 25g / L Na 2 S 2 o 3 ·5H 2 O, 5g / L K 2 SO 3 and 5g / L H 3 BO 3 mixed solution;

[0107] (2) Select a cathode that can move continuously, the cathode adopts a stainless steel strip, and the surface of the cathode stainless steel strip is polished;

[0108] (3) Adjust the parameters of electrochemical deposition to conduct constant current mode electrodeposition, and the current density range during the constant current mode is 1mA / cm 2 ;

[0109] (4) The cathode stainless steel belt passes through the electrodeposition tank, cleaning tank and collection tank continuously and sequentially;

[0110] (5) In the electrodeposition tank, the cathode stainless steel belt moves continuously in the electrolyte, the part of the cathode stainless steel belt immersed in the electrolyte is 10cm in lengt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| shear strength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com