Intelligent factory for semiconductor packaging test

A technology for packaging and testing semiconductors, which is applied in semiconductor/solid-state device testing/measurement, semiconductor/solid-state device manufacturing, electrical components, etc., and can solve the problem of compound robot semiconductor material boxes and intelligent fixed material racks that do not have open access to semiconductor materials and other issues, to achieve the effect of material transmission routing and solve the effects of diversity and complexity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

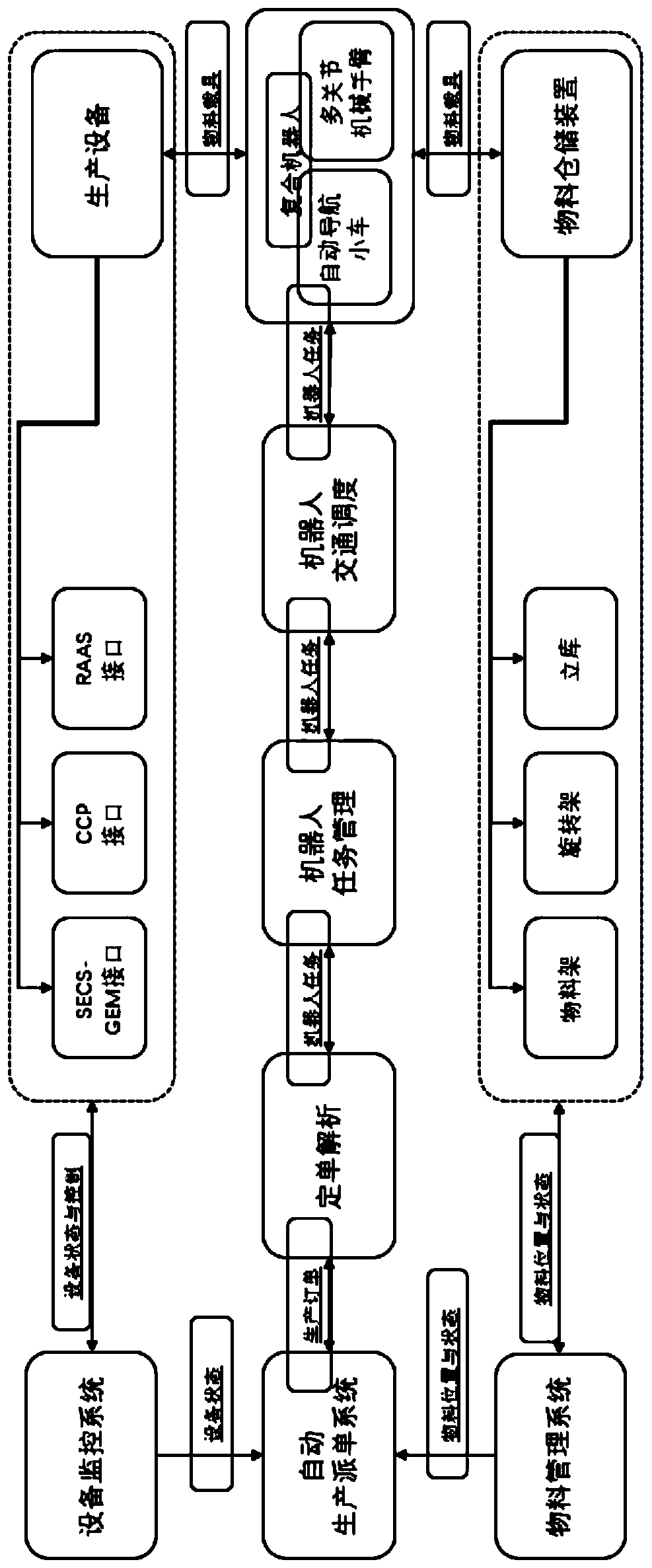

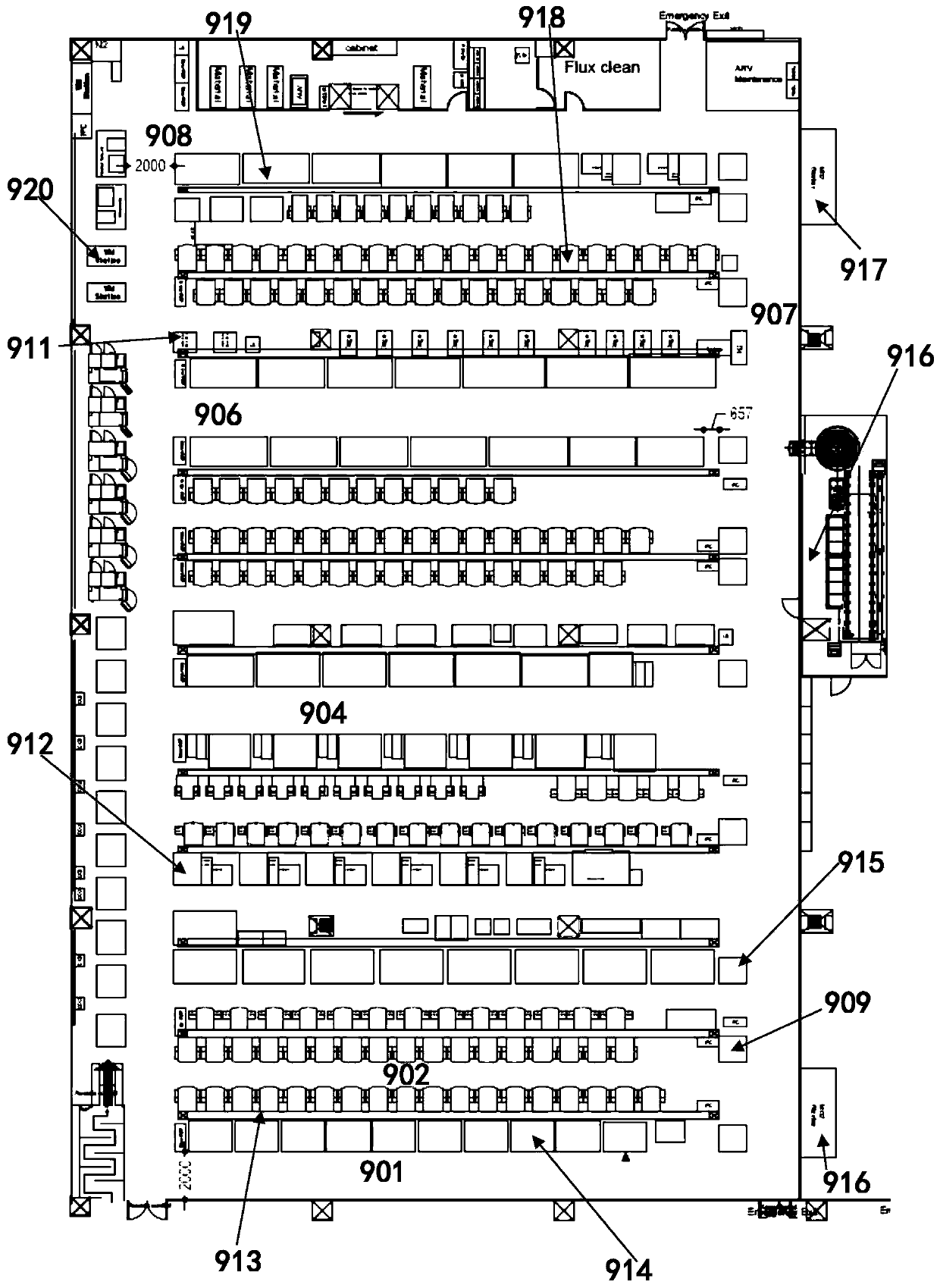

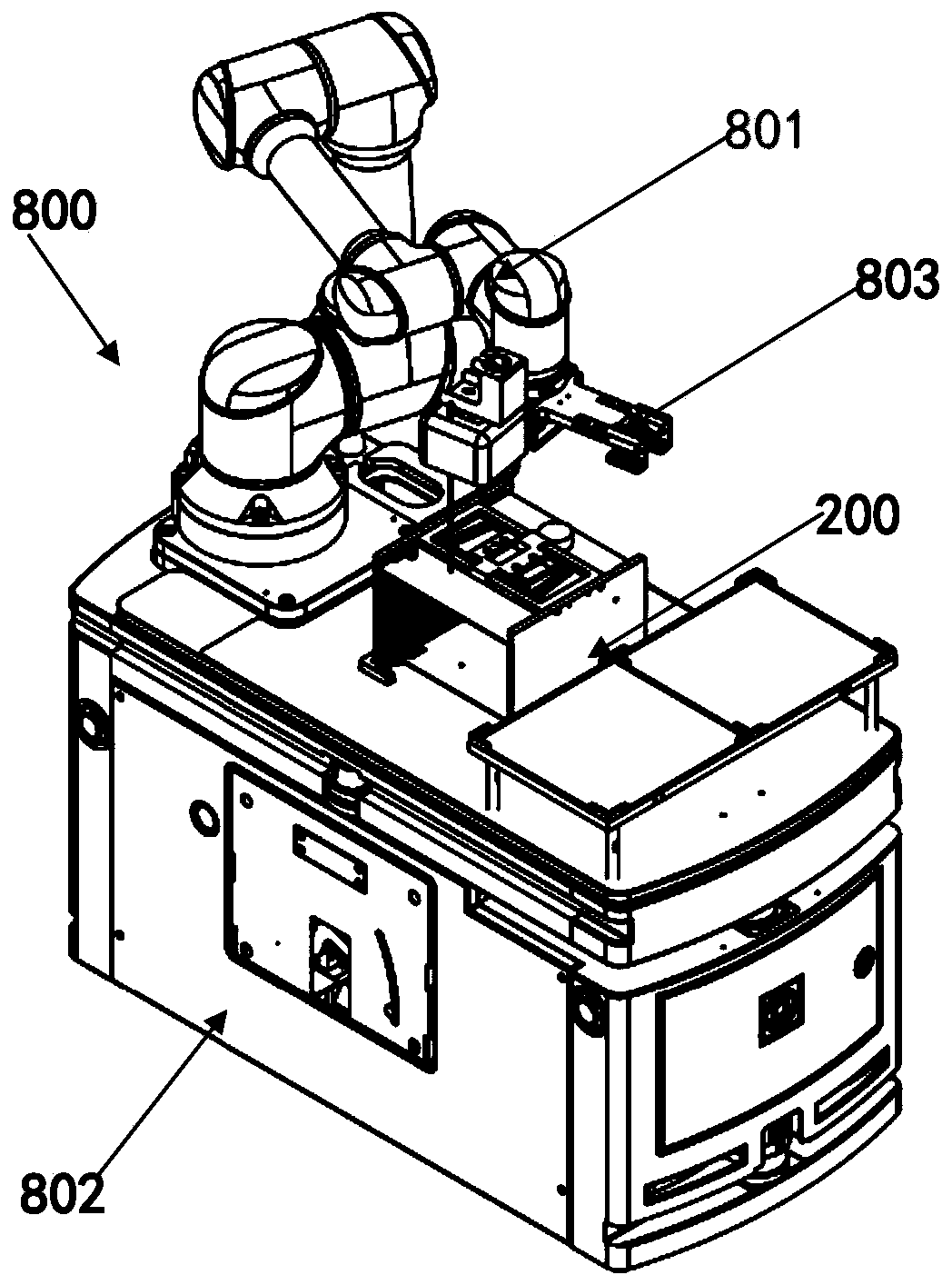

[0062] Based on the above-mentioned inventive concept, with reference to Figures 1 to 12 , according to the first embodiment of the semiconductor packaging and testing smart factory of the present invention, the semiconductor packaging and testing smart factory can automatically transfer materials between production stations in different process steps. refer to figure 2 , each row of the factory workshop includes multiple workstations of the same type. But different rows can correspond to different types of workstations. That is to say, before the present invention, the material handling between different rows needs to be carried out manually. After the implementation of the present invention, the material handling between different rows is realized by a composite robot, so as to achieve the purpose of improving the degree of automation. refer to figure 1 , the semiconductor packaging and testing intelligent factory includes a composite robot, production equipment, materi...

no. 2 approach

[0176] As one of the key points of the invention of this patent application, the facility layout of the semiconductor packaging and testing smart factory can be arranged in various ways, refer to Figures 1 to 12 , according to the second embodiment of the semiconductor packaging and testing smart factory of the present invention, the semiconductor packaging and testing smart factory includes a material carrier, a composite robot, production equipment, and a material storage device;

[0177] The composite robot can take out materials from the material storage device, and transport the materials to the production equipment by means of the material carrier, or, the composite robot can extract materials from the production equipment in the first process step taking out the material, and transporting the material to the production equipment of the second process step by means of the material carrier;

[0178] The material storage device includes a fixed material rack, a rotating m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com