A kind of steel bundle end face intelligent welding brand device and method thereof

An end face and welding plate technology, applied in the field of steel bundle intelligent welding plate device, can solve the problems of harsh environment, insufficient intelligence, and high danger in the working area, and achieve the effect of meeting the rhythm demand

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

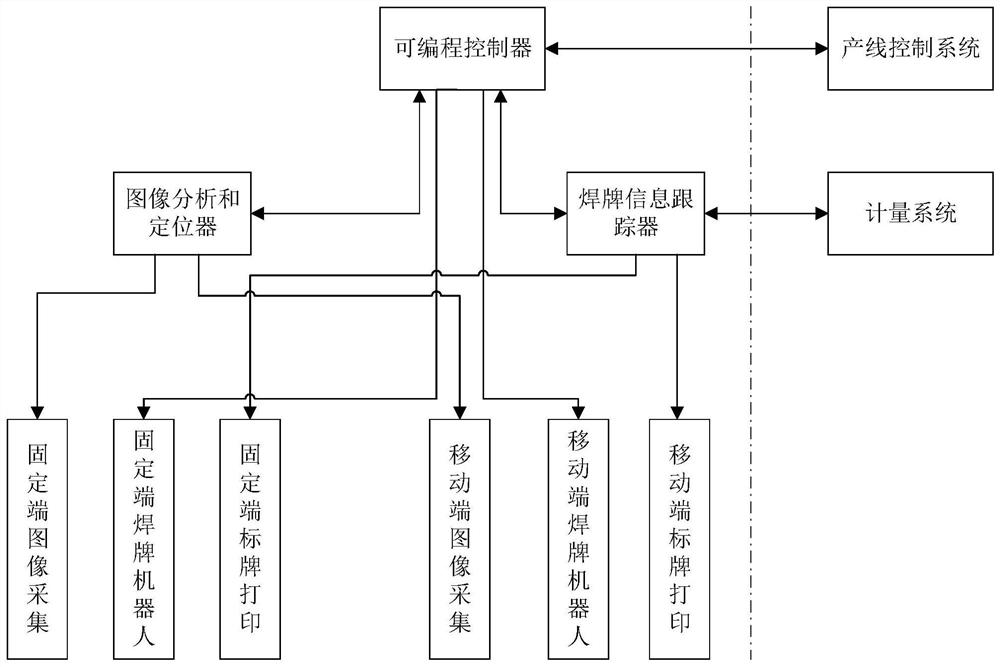

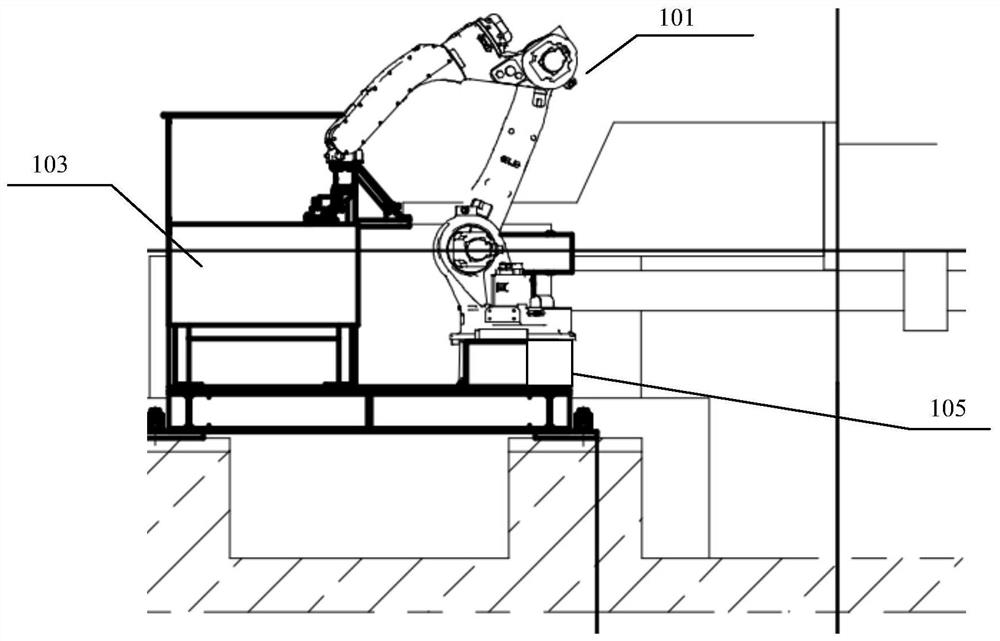

[0040]A set of steel bales of steel bales proposed in the present invention, using an industrial robot combined with machine vision to realize the full automatic unmanned buck function in the production process.

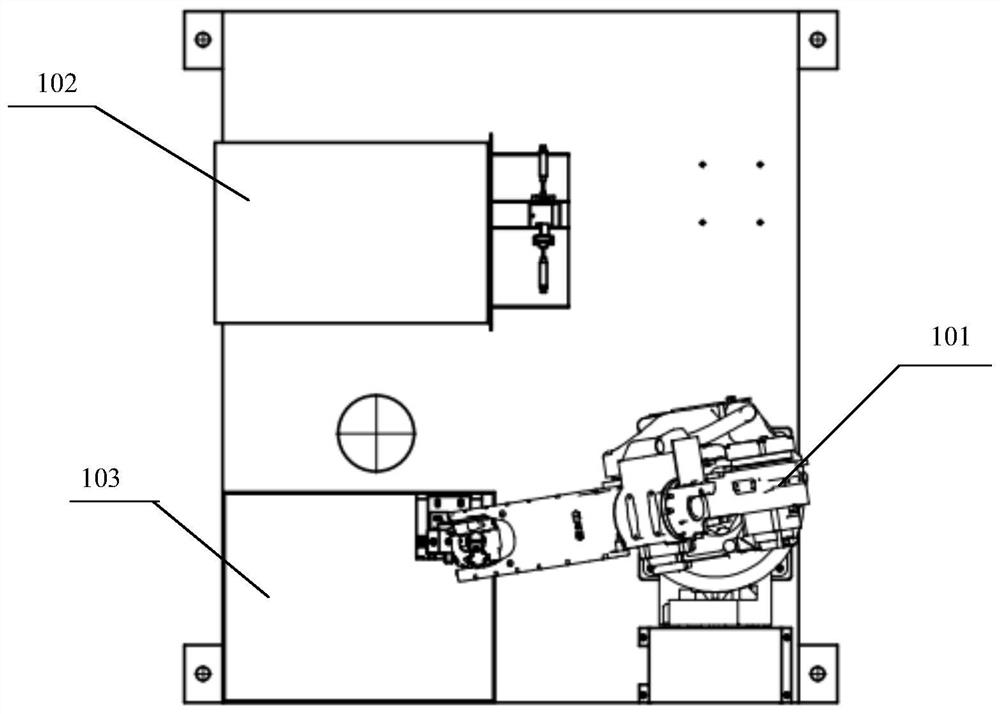

[0041]After the steel bundles produced by the bar, after weighing, the original count system will send the signage data including specifications, weight and other information to the buck information tracker, and the adder information tracker adds information into the steel bundle tracking queue. At the same time, the heavy finished steel bundle is sequentially delivered to the bundle transport chain waiting to be soldered, the programmable controller of the buck system receives the transport chain movement signal of the production line system, thereby calculating the position of the non-welded steel bundle Real-time tracking, based on the previous buck position calculation and determine the next bundle of unparalleled steel bundles completely enter the image acquisition camer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com