Tea oil production raw material smashing device

A raw material crushing and camellia oil technology, which is applied in the direction of fat oil/fat production, fat generation, drying gas arrangement, etc., can solve the problems of poor crushing effect, lack of automatic feeding device, uneven raw material crushing effect, etc., and achieve automatic feeding materials, guarantee the use effect, and achieve the effect of dehumidification function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

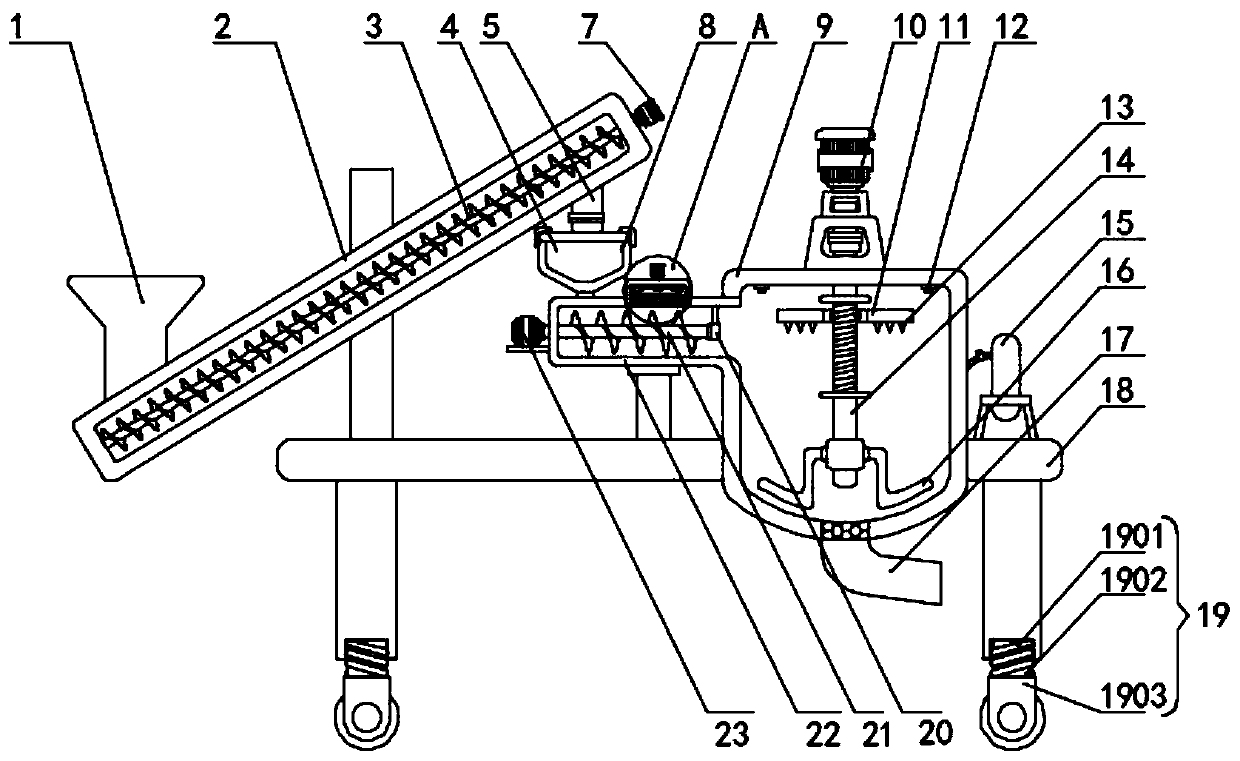

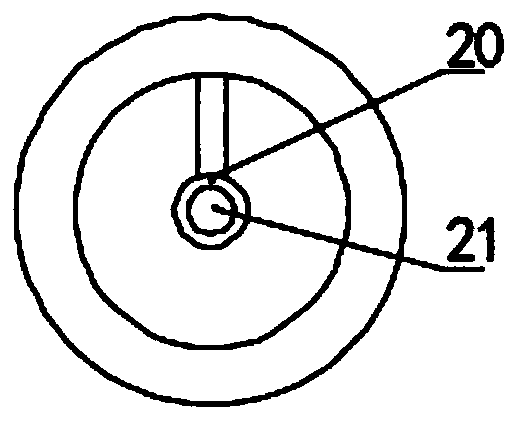

[0036] see Figure 1-5 , a raw material crushing device for camellia oil production, comprising a support seat 18, the top of the support seat 18 is sequentially installed with a feeding bin 2, a transfer bin 22, a crushing bin 9 and a water storage bin 15, and a rotating mechanism is fixedly installed on the top of the crushing bin 9 10. The output end of the rotating mechanism 10 is rotatably connected with a rotating shaft 14, and the bottom of the rotating shaft 14 is fixedly equipped with a pulverizing paddle 16. The outer wall of the rotating shaft 14 is provided with a threaded section, and the outer wall of the threaded section is connected with a knife seat 11 by threading. An auxiliary cutter head 13 is fixedly installed on the bottom of the seat 11, a feeding port 17 is fixedly installed on the bottom of the crushing bin 9, a rotating motor 23 is fixedly installed on one side of the horizontal end of the transfer bin 22, and the output end of the rotating motor 23 is...

Embodiment 2

[0038] see figure 1 A storage bin 1 is fixedly installed on the top of the feeding bin 2, a lifting motor 7 is fixedly installed on the outside of the feeding bin 2, and the output end of the lifting motor 7 is connected to the first threaded rod 3 in rotation, and the first threaded rod 3 is penetrated in the feeding bin 2 cavity, the inner cavity of the hopper 4 is fixedly equipped with a material level sensor 8, and the bottom of the feeding bin 2 is provided with a discharge port 5 connected to the hopper 4. When the material level sensor 8 detects that the raw material in the hopper 4 is lower than the predetermined value, the lifting motor 7 automatically Open, the first threaded rod 3 puts the raw materials in the storage bin 1 into the hopper 4 through the outlet 5, and when the material level in the hopper 4 reaches a predetermined value, the lifting motor 7 is controlled to turn off, so that the feeding bin 2 stops feeding , to realize the automatic feeding function ...

Embodiment 3

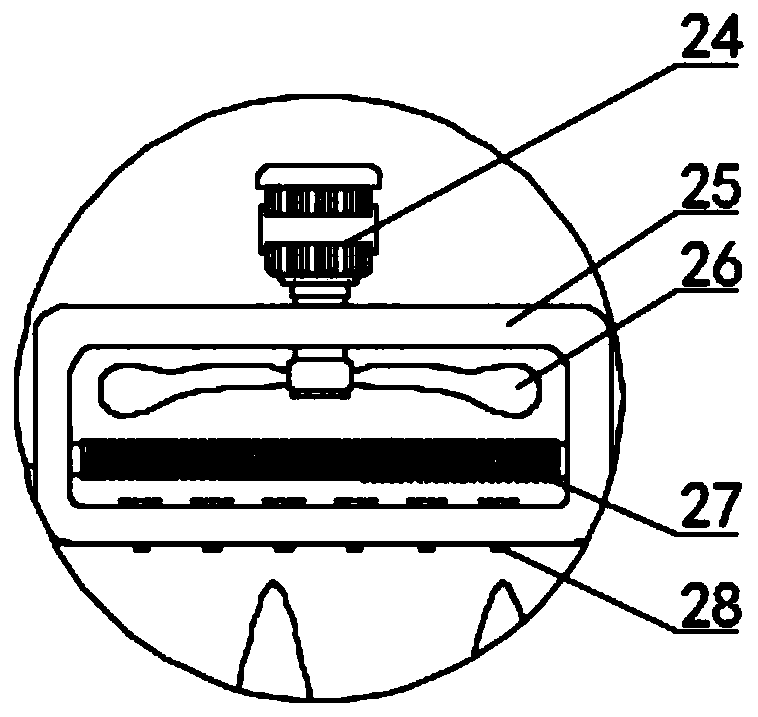

[0040] see figure 2 , the top of the transfer bin 22 is fixedly equipped with a heating bin 25, the inner cavity of the heating bin 25 is fixedly installed with a heating tube 27, the top of the heating bin 25 is fixedly installed with a heating motor 24, and the output end of the heating motor 24 is connected to a fan blade 26 in rotation, and the heating bin 25 There is an air outlet 28 on the top, and the heating tube 27 inside the heating chamber 25 works to generate hot air. At this time, the heating motor 24 drives the fan blade 26 to rotate, so that the hot air generated by the heating tube 27 contacts the raw material through the air outlet 28, realizing the dehumidification function of the device. .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com