Floor-sweeping-capable duster equipment used in thermal power plant

A technology for thermal power plants and dust collectors, applied in the fields of smoke removal, fire rescue, chemical instruments and methods, etc., can solve the problems of difficult dust adsorption, waste of resources, low fire extinguishing efficiency, etc., achieve good sweeping function, ensure cleanliness, Good dust removal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

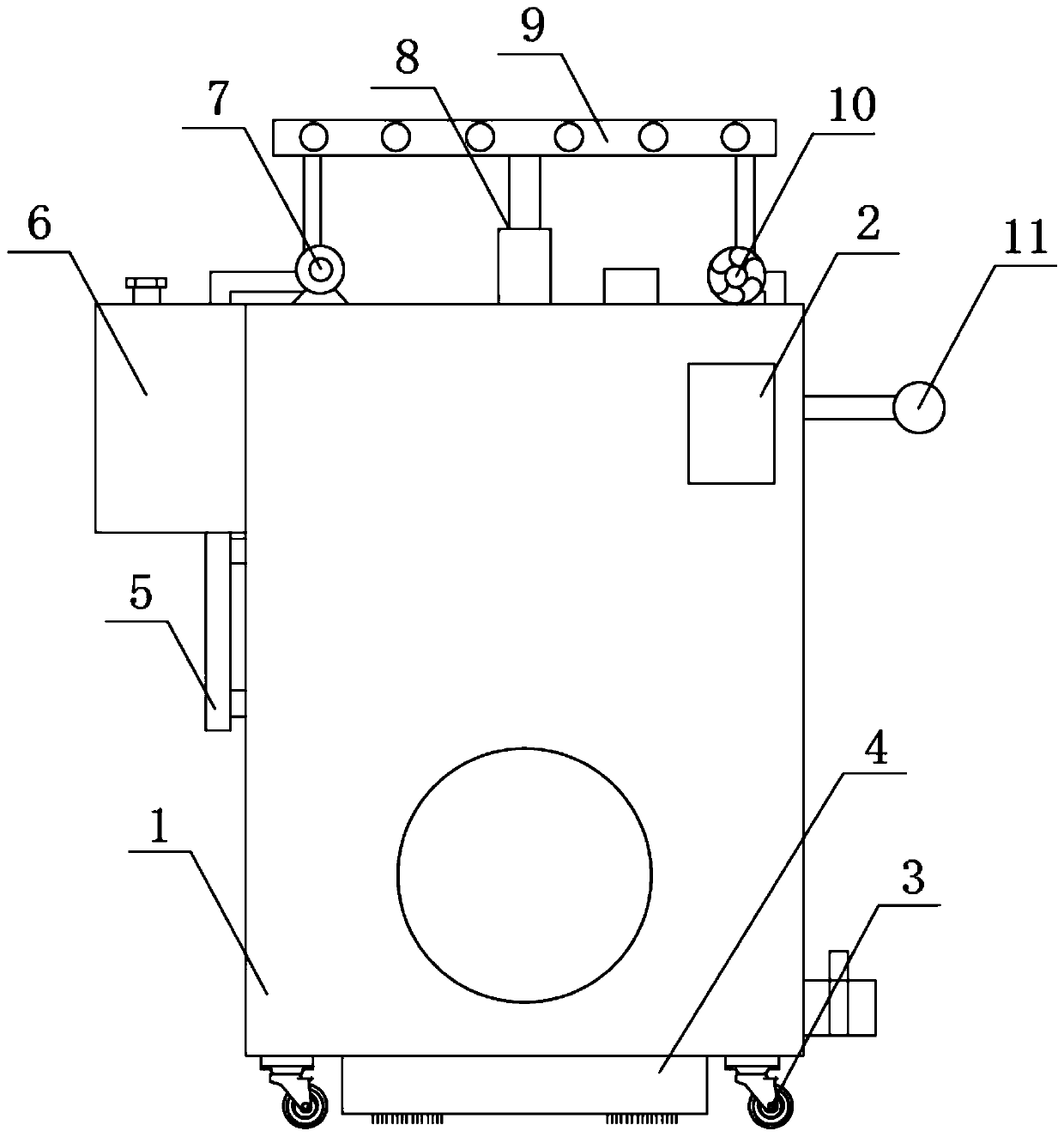

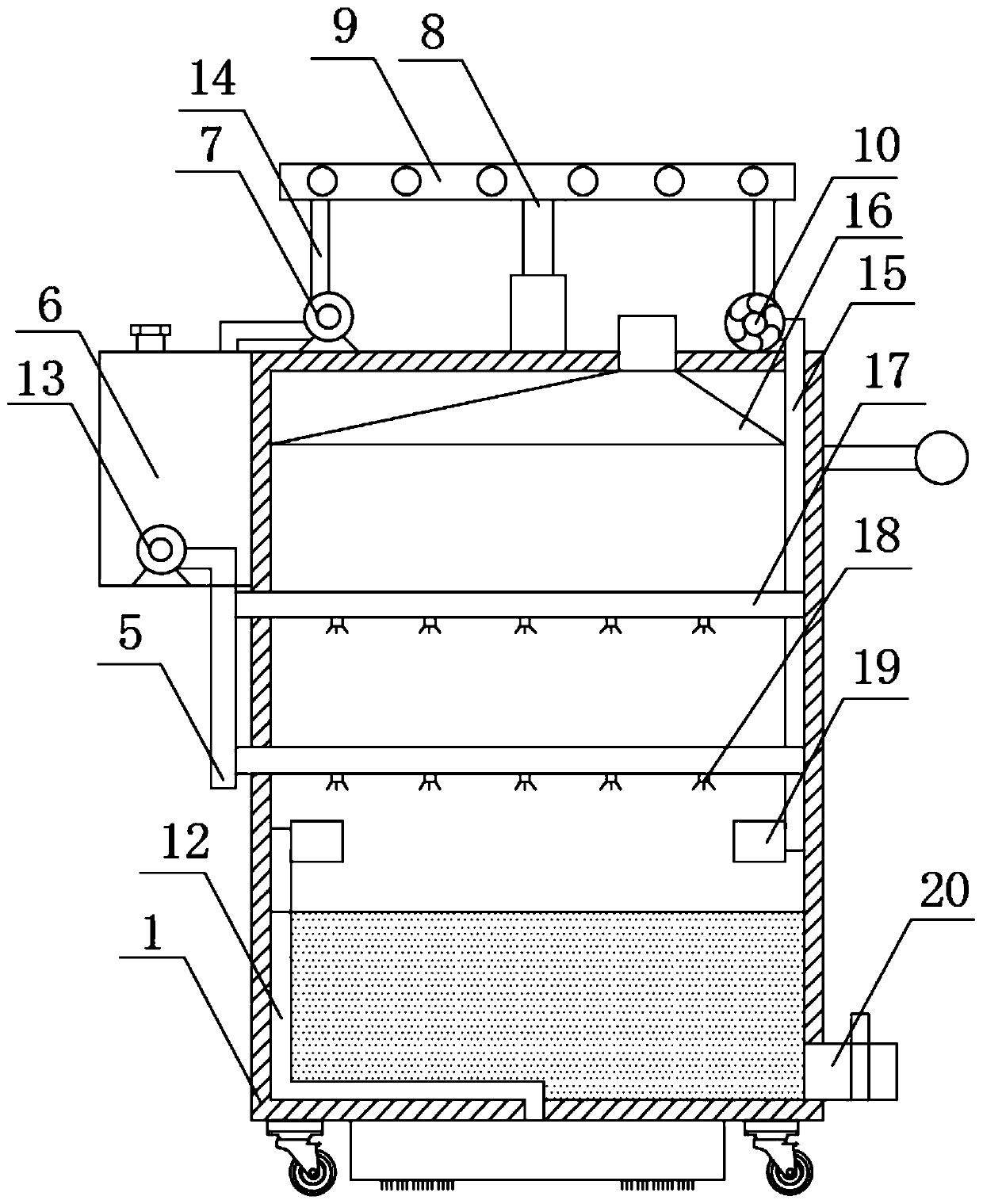

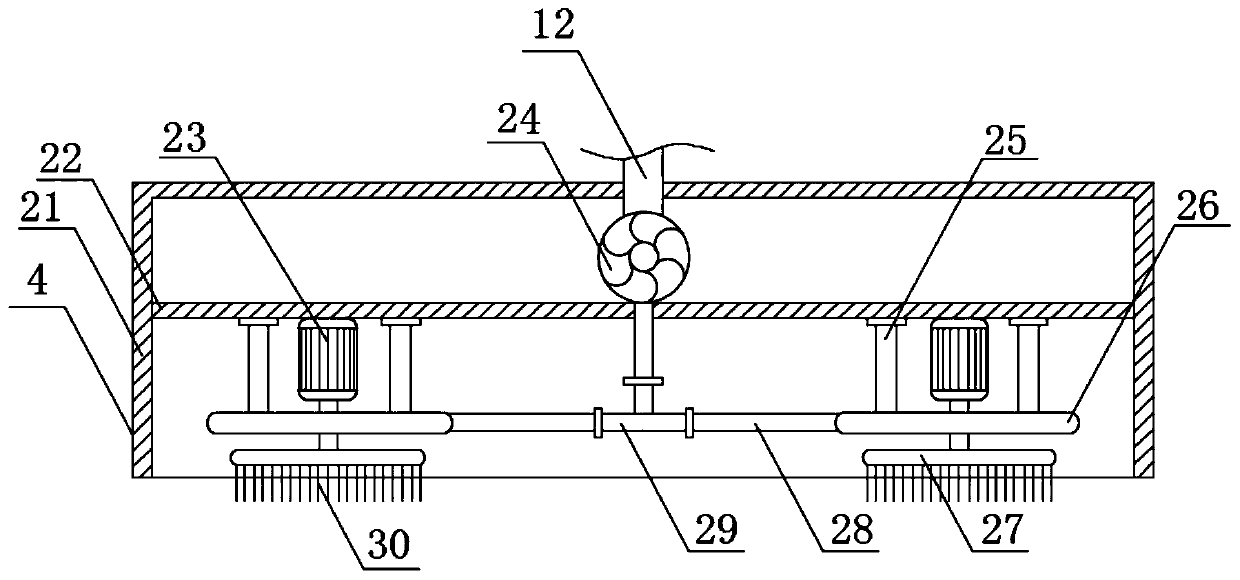

[0030] see Figure 1-6, the present invention provides a technical solution: a sweepable dust collector equipment for a thermal power plant, including a dust removal box 1, a controller 2 and a universal wheel 3, the controller 2 is fixedly installed on one side of the outer wall of the dust removal box 1, and the The universal wheel 3 is fixedly installed at the four corners of the bottom end of the dust removal box 1, and the bottom end of the dust removal box 1 is fixedly installed with a sweeping mechanism 4 inside the universal wheel 3, and the sweeping mechanism 4 includes a housing 21 and a partition 22. The casing 21 is fixedly mounted on the surface of the bottom end of the dust removal box 1, the partition 22 is welded inside the casing 21, the upper end of the partition 22 is fixedly installed with a No. 2 fan 24, and the outlet end of the No. 2 fan 24 is fixedly connected with two No. 2 air inlet pipe 12, the end of No. 2 air inlet pipe 12 away from the outlet end ...

Embodiment 2

[0037] see figure 1 , figure 2 , Figure 5 with Image 6 , the present invention provides a technical solution: a thermal power plant sweepable dust collector equipment, a water tank 6 is fixedly installed on one side of the outer wall of the dust removal box 1, and an electric telescopic is fixedly installed at the top of the dust removal box 1 close to the axis. Rod 8, the model of the electric telescopic rod 8 is TGA-100, the output end of the electric telescopic rod 8 is fixedly installed with a No. , and the No. 1 dust suction branch pipe 34 is provided with three groups, and one end of the No. 1 dust suction branch pipe 34 is fixedly equipped with a dust collection cover 36, and one side of the No. 1 dust suction main pipe 9 inner wall is fixedly installed with a water spray main pipe 33. One side surface of the water spray main pipe 33 is fixedly connected with a water spray branch pipe 35, one end of the water spray branch pipe 35 runs through the No. Water pump 7...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com