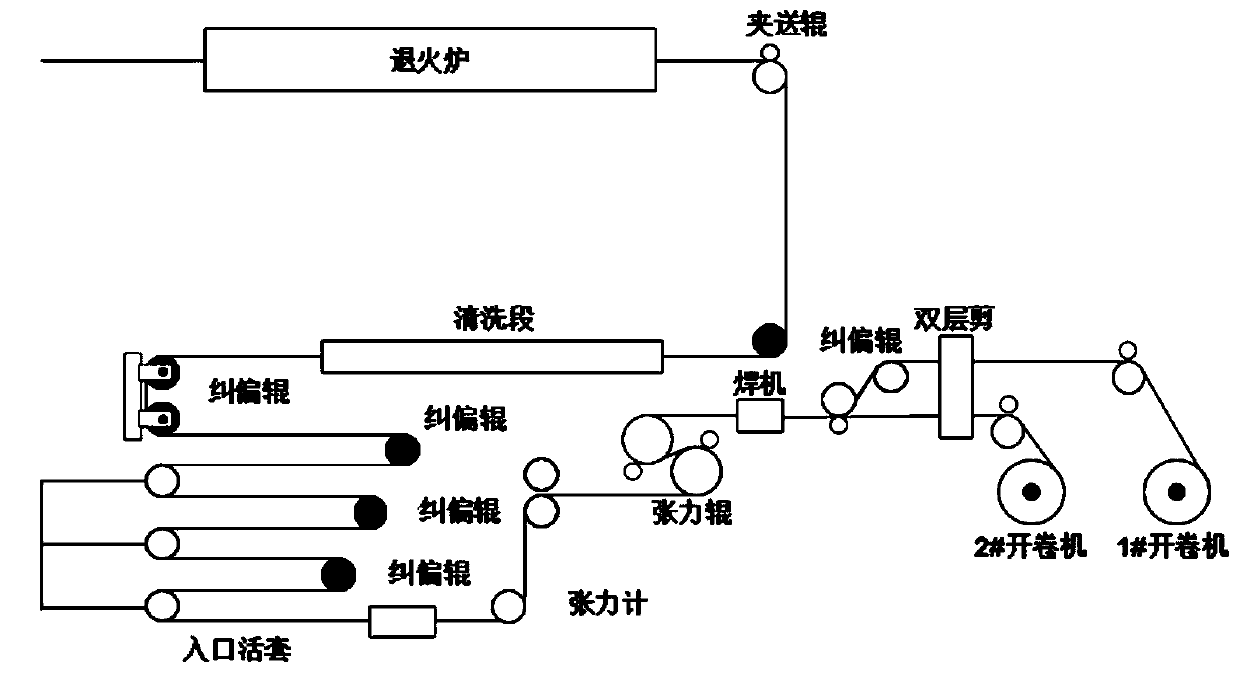

Full-automatic tail throwing control method and system for cold rolling continuous annealing unit

A technology of continuous annealing unit and control method, which is applied in the direction of rolling mill control device, metal rolling, metal rolling, etc., which can solve the problems of low machine composition rate and large amount of waste for strip tail cutting, so as to reduce the amount of waste Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

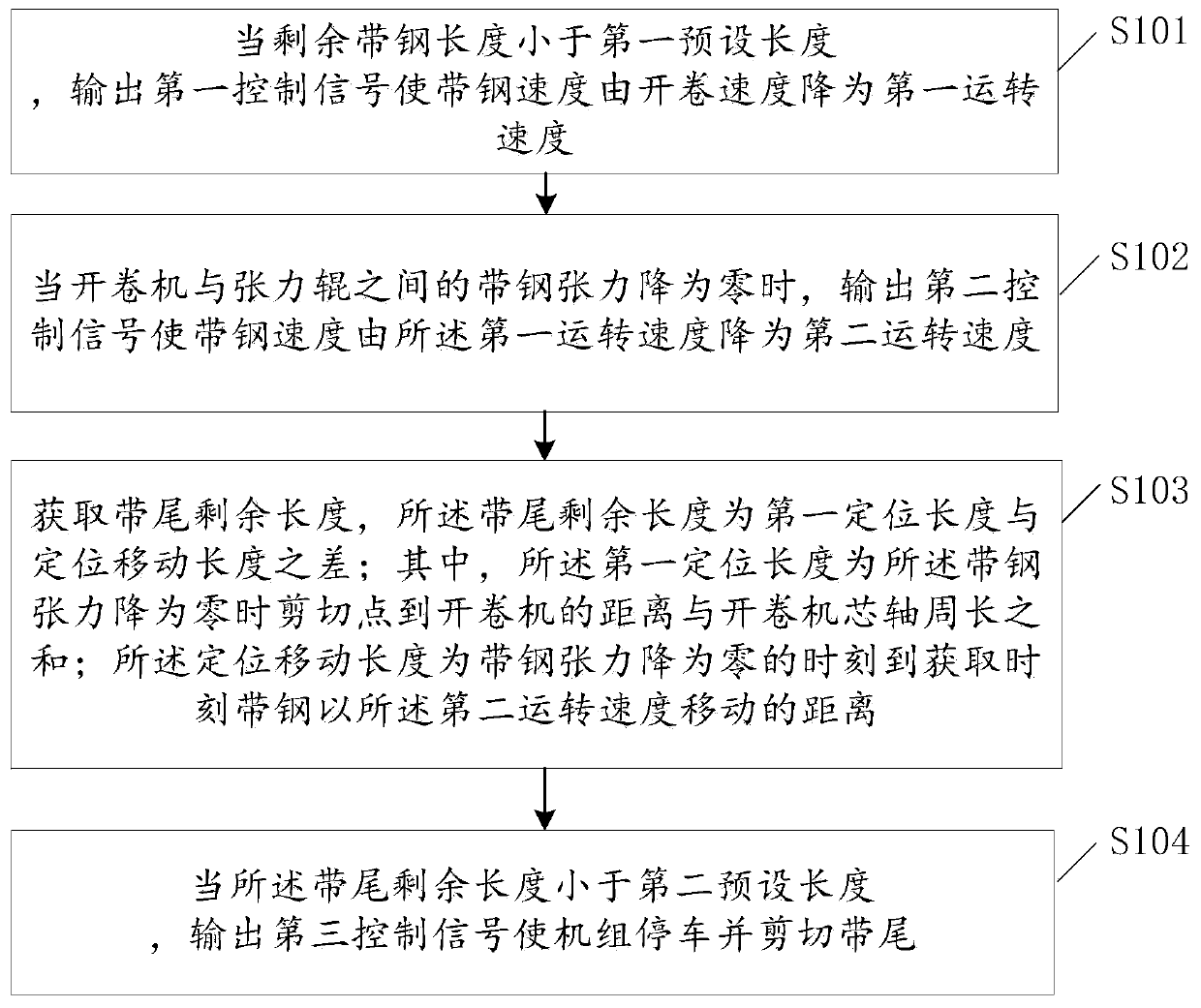

[0039] Such as figure 2 As shown, this embodiment provides a method for fully automatic tailing control of a cold rolling continuous annealing unit, including:

[0040] S101: When the remaining strip length is less than the first preset length, output the first control signal to reduce the strip speed from the uncoiling speed to the first running speed;

[0041] As an optional embodiment, the first preset length is 18-20 meters.

[0042]The first preset length can be 18 meters, 19 meters, or 20 meters. In this embodiment, the first preset length is 20 meters. When the remaining strip length is less than 20 meters, start to slow down and flick. Due to the limited tail-flick time, the first preset length cannot be set too large, otherwise it will lead to too much waste in the limited tail-flick time.

[0043] The reason why the set tail time is limited is that the stock of the inlet looper strip is only enough to ensure the continuous operation of the central section. If the ...

Embodiment 2

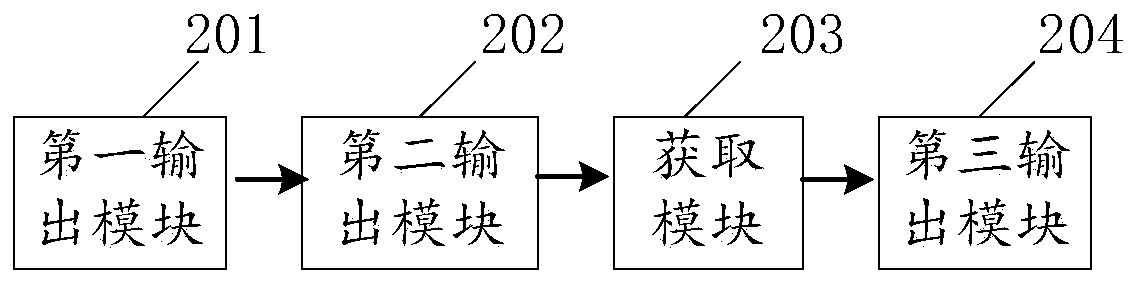

[0073] Such as image 3 As shown, based on the same inventive concept, this embodiment provides a fully automatic tailing control system for a cold rolling continuous annealing unit, including:

[0074] The first output module 201 is used to output a first control signal to reduce the speed of the strip from the uncoiling speed to the first operating speed when the remaining strip length is less than the first preset length;

[0075] The second output module 202 is used to output a second control signal to reduce the speed of the strip from the first operating speed to the second operating speed when the strip tension between the uncoiler and the tension roller drops to zero;

[0076] The obtaining module 203 is used to obtain the remaining length of the tape tail, the remaining length of the tape tail is the difference between the first positioning length and the positioning moving length; wherein, the first positioning length is the shearing length when the tension of the st...

Embodiment 3

[0090] Based on the same inventive concept, this embodiment provides a computer-readable storage medium, on which a computer program is stored, and on which a computer program is stored, and when the computer program is executed by a processor, the following steps are implemented:

[0091] When the remaining strip length is less than the first preset length, output the first control signal to reduce the strip speed from the uncoiling speed to the first running speed; when the strip tension between the uncoiler and the tension roller drops to zero, output the first control signal Two control signals reduce the speed of the strip steel from the first operating speed to the second operating speed; obtain the remaining length of the belt tail, and the remaining length of the belt tail is the difference between the first positioning length and the positioning movement length; wherein, the first positioning The length is the sum of the distance from the shear point to the uncoiler an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com