Coating production line control method

A technology of a coating production line and a control method, which is applied in the direction of sputtering coating, vacuum evaporation coating, ion implantation coating, etc., can solve the problems of insufficient intelligence level and narrow space, and save manpower, material resources and floor space , to provide the effect of production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] Hereinafter, the present invention will be further described in detail and completely in combination with examples and comparative examples.

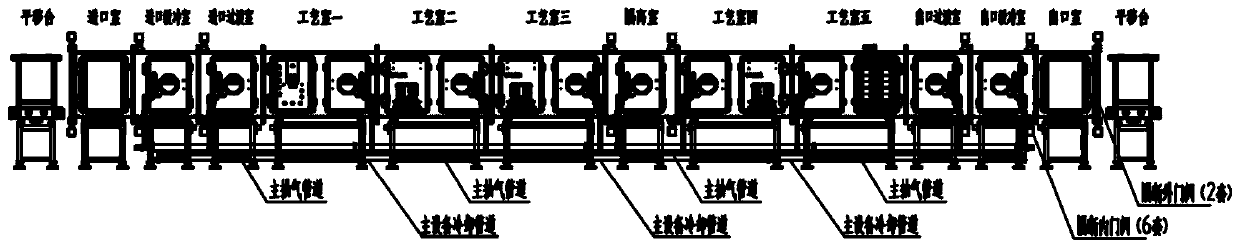

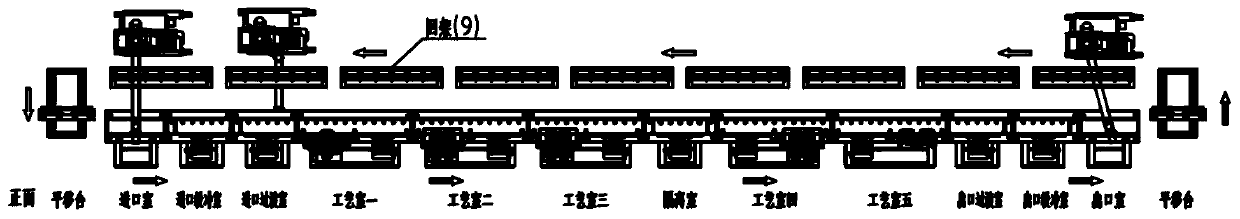

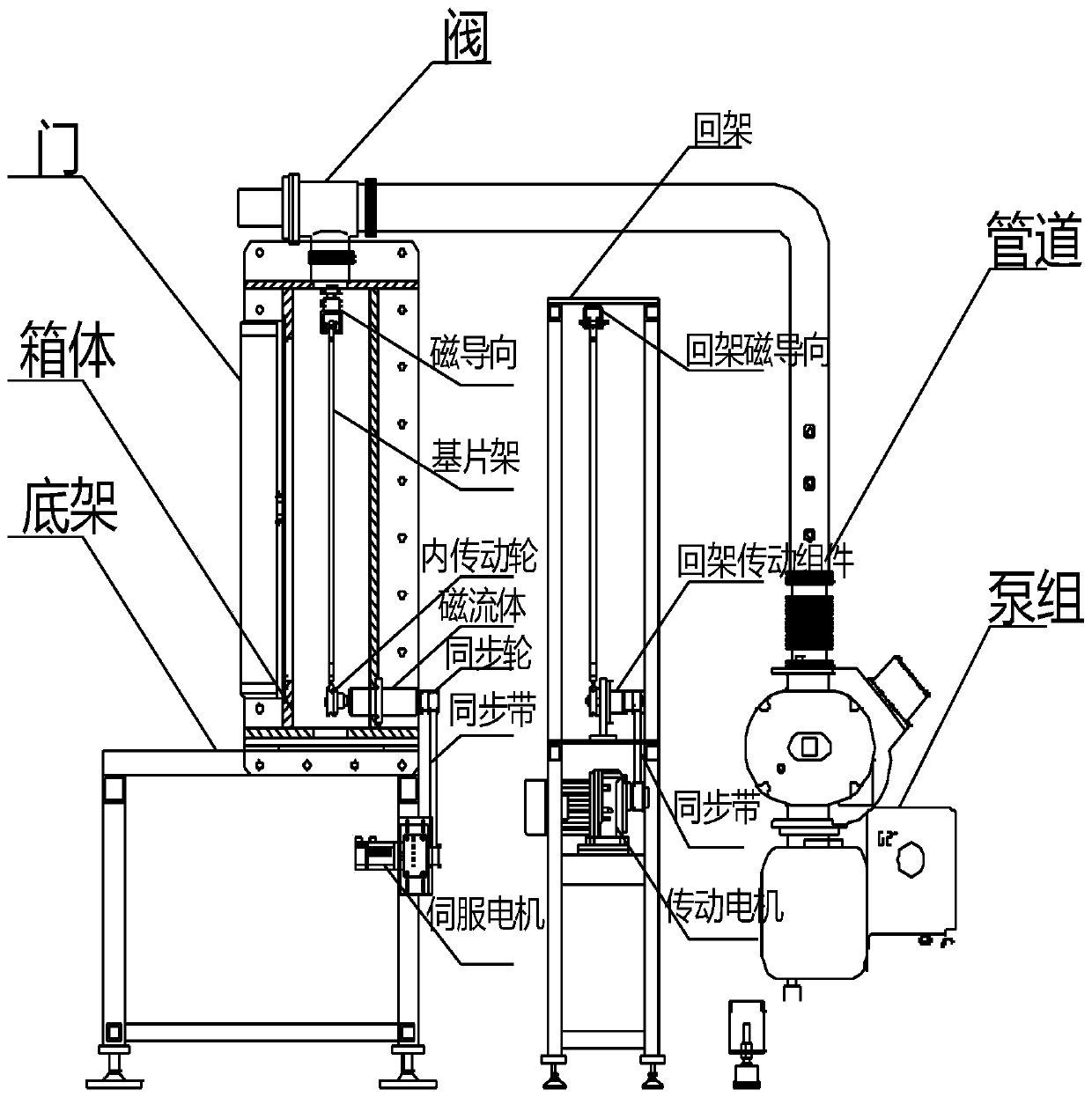

[0055] See Figure 1 to Figure 8 As shown, this application provides a coating production line control method, which is applied to Figure 1 to Figure 7 In the host computer corresponding to the coating production line shown, the transmission line and the coating production line are connected end to end to form an annular assembly line, and the host computer is communicatively connected with the transmission line and the coating production line, so that the upper computer communicates the transmission line and the coating production line. The coating production line is controlled, and the method includes:

[0056] S202: Detect whether a substrate is introduced into the inlet chamber, and when the substrate is introduced into the inlet chamber, each chamber of the production line is evacuated to a medium vacuum range by a vacuum pump, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com