Production method and production device for superfine-denier POY (polyester pre-oriented yarn) product

A production method and ultra-fine denier technology, applied in the field of polyester filaments, can solve the problems of decreased spinning quality, heat loss, and uneven melt temperature of spinnerets

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention is further described below in conjunction with specific embodiment, but protection scope of the present invention is not limited thereto:

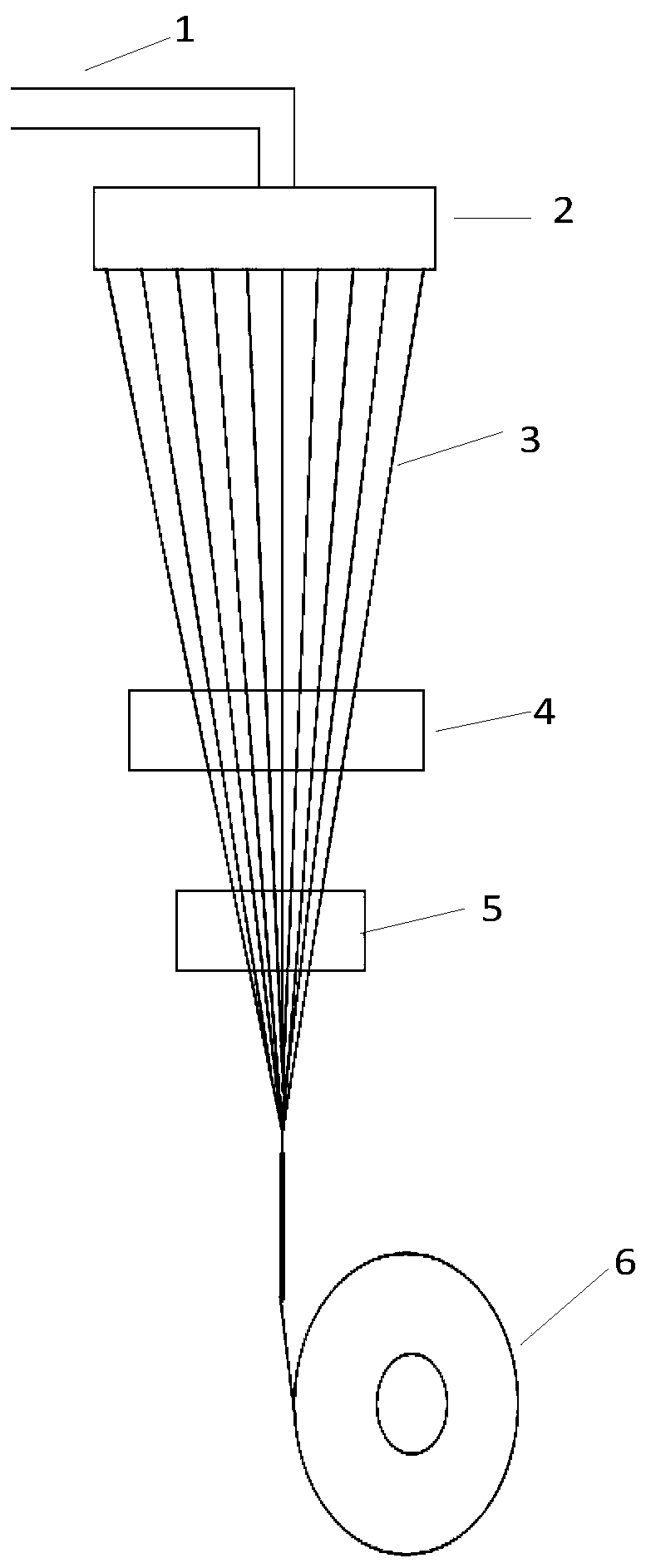

[0016] With reference to accompanying drawing, a kind of production method of superfine denier POY product comprises the following steps,

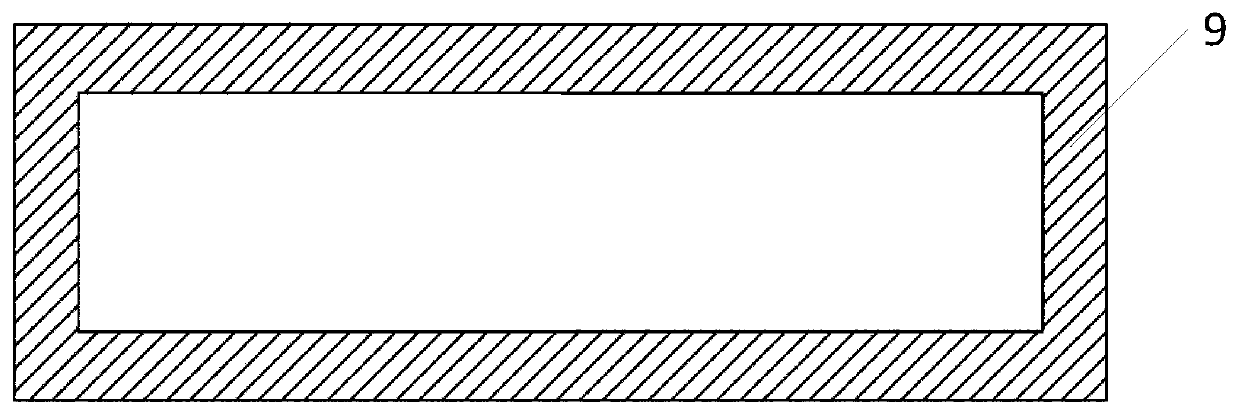

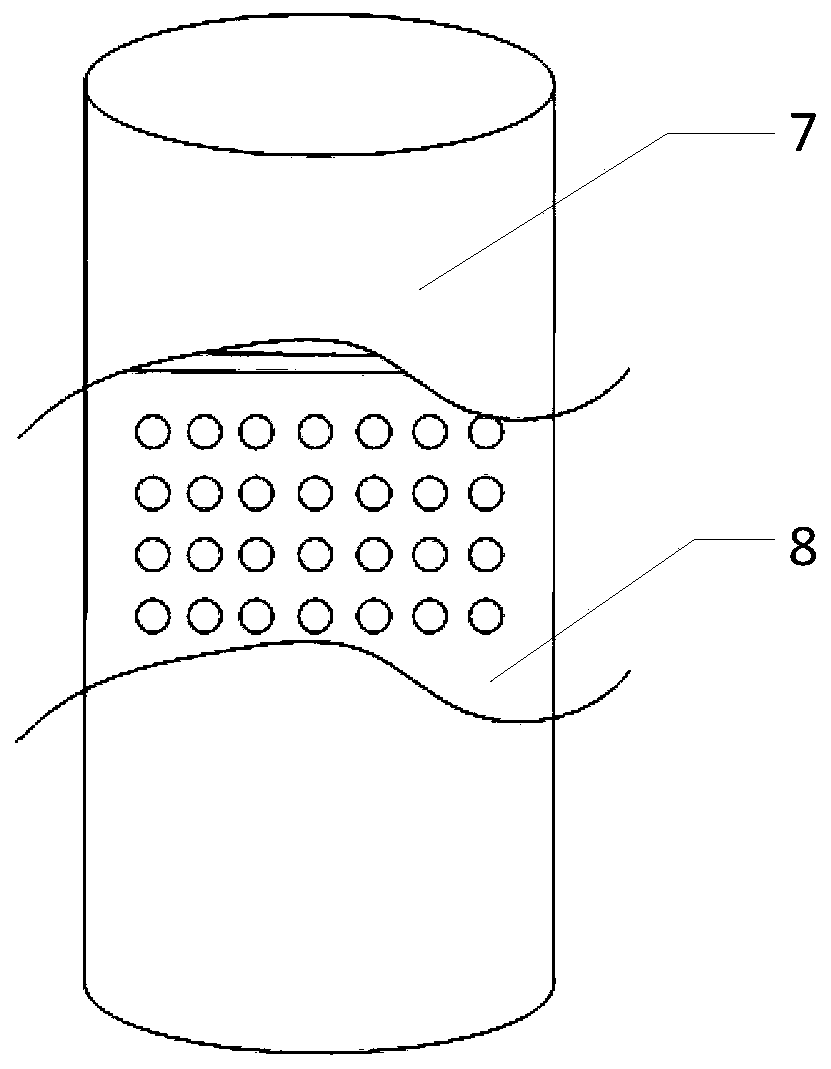

[0017] Step 1: Add an insulating material layer in the gap between the spinning box and the surrounding blowing box. There is a fixing frame on the outside of the insulating material layer, and the fixing frame will press the insulating material layer tightly on the spinning box and the surrounding blowing box. In the gap between them, the air circulation can be blocked and the heat dissipation of the spinneret can be reduced; the central insert plate of the air duct is installed in the surrounding blower, and there are through holes distributed on the central insert plate of the air duct to stabilize the wind speed;

[0018] The second step: using semi-dull polyester melt ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com