Thermal transfer printing process for polyesters

A thermal transfer printing and thermal transfer technology, applied in the field of polyester printing, can solve the problems of drying operation, high plate making costs, waste of resources, etc., and achieve the effects of reducing power and energy consumption, improving drying temperature, and ensuring overall quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

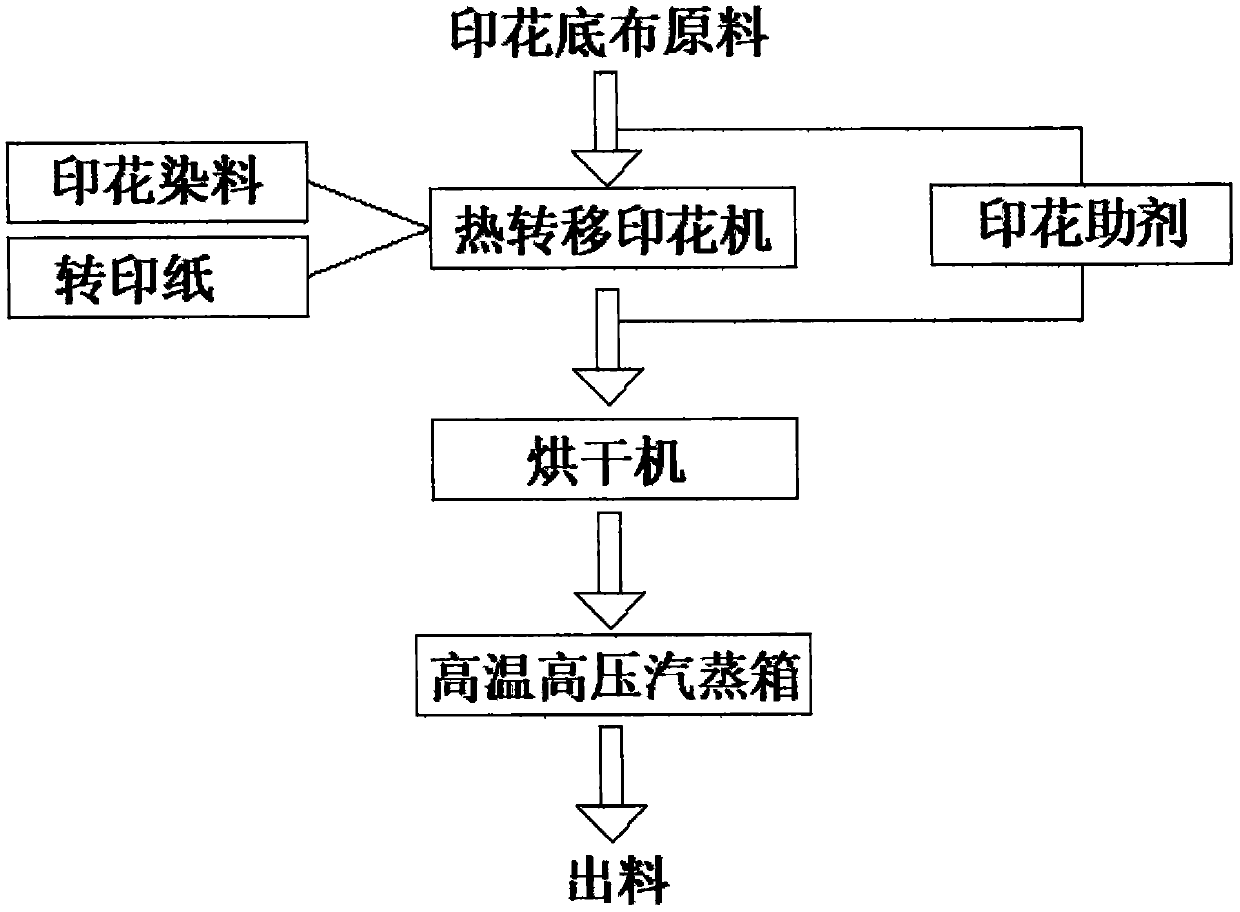

[0024] see Figure 1-2 , the embodiment provided by the present invention: the thermal transfer printing process of polyester, needs to pass printing base cloth raw material, thermal transfer printing machine, printing auxiliary agent, printing dyestuff, transfer printing paper, dryer and high temperature and high pressure steam box, has been Reach the demand of production technology, it is characterized in that: comprise following five steps:

[0025] Step 1: The raw material of the printed base cloth needs to be selected from light-colored fabrics such as bleached and natural white, and the selected printed base cloth raw materials are arranged in the heat transfer printing machine;

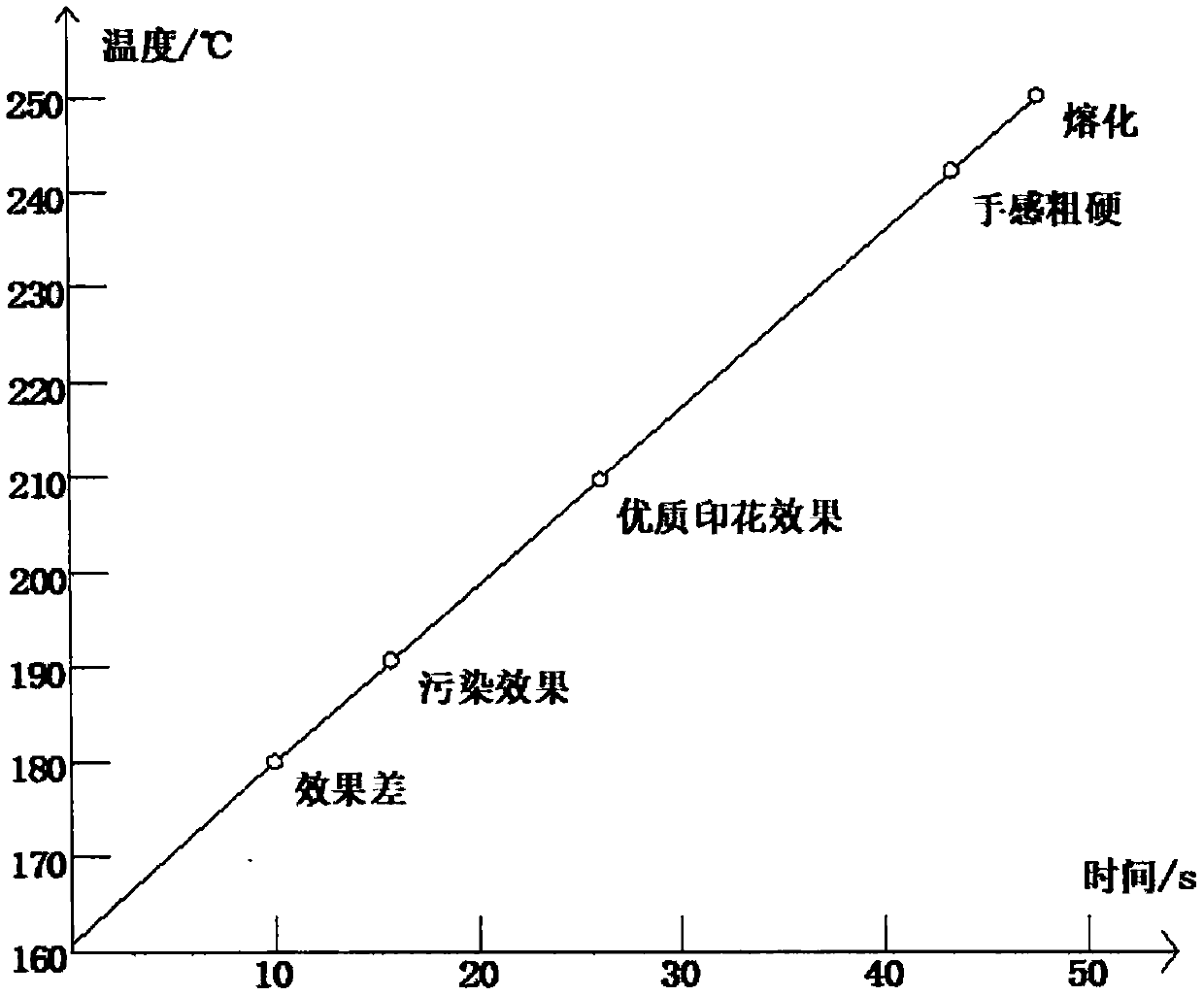

[0026] Step 2: Arrange the printing base fabric raw materials into the heat transfer printing machine, and then arrange the printing dye and transfer paper on the heat transfer printing machine, and the heat transfer printing machine will print on the printing base cloth raw materials through h...

Embodiment 2

[0035] Reactive Dye Direct Printing

[0036] The main production process of polyester / cotton printing is the same paste printing with disperse dyes and reactive dyes. The process design can be treated with one-time fixation or two-time fixation, which is commonly known as disperse-active process.

[0037] The printing workshop with high-temperature steamer adopts one-time fixation process, which can shorten the production cycle and simplify the process flow.

[0038] Printing→drying→high temperature steaming (175~188℃, 6~7.5 minutes)→flat washing→drying→finishing.

[0039] The dyestuff is alkali-resistant (baking soda) disperse dyes, and reactive reactive dyes. The alkali agent used for color fixing should be reduced as much as possible. Disperse dyes that are sensitive to alkali should not be used, because alkaline colorants are prone to discoloration. Such as dark blue HGL (S-2GL), from blue to gray, after steaming treatment, the color becomes dark.

[0040] Cotton printin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com