Machining method for drill bit with blade inclined groove structures for machining composite material

A processing method and composite material technology, which are applied in the field of drilling tools in machining, can solve the problems of difficult to realize fiber composite materials, the inlet fibers of the composite materials cannot play a good cutting effect, and the inlet tear is serious, and reduce the inlet Effect of tear damage, suppression of entrance tear and burr damage, and efficient hole making

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The specific implementation manners of the present invention will be described in detail below in conjunction with the drawings and technical solutions.

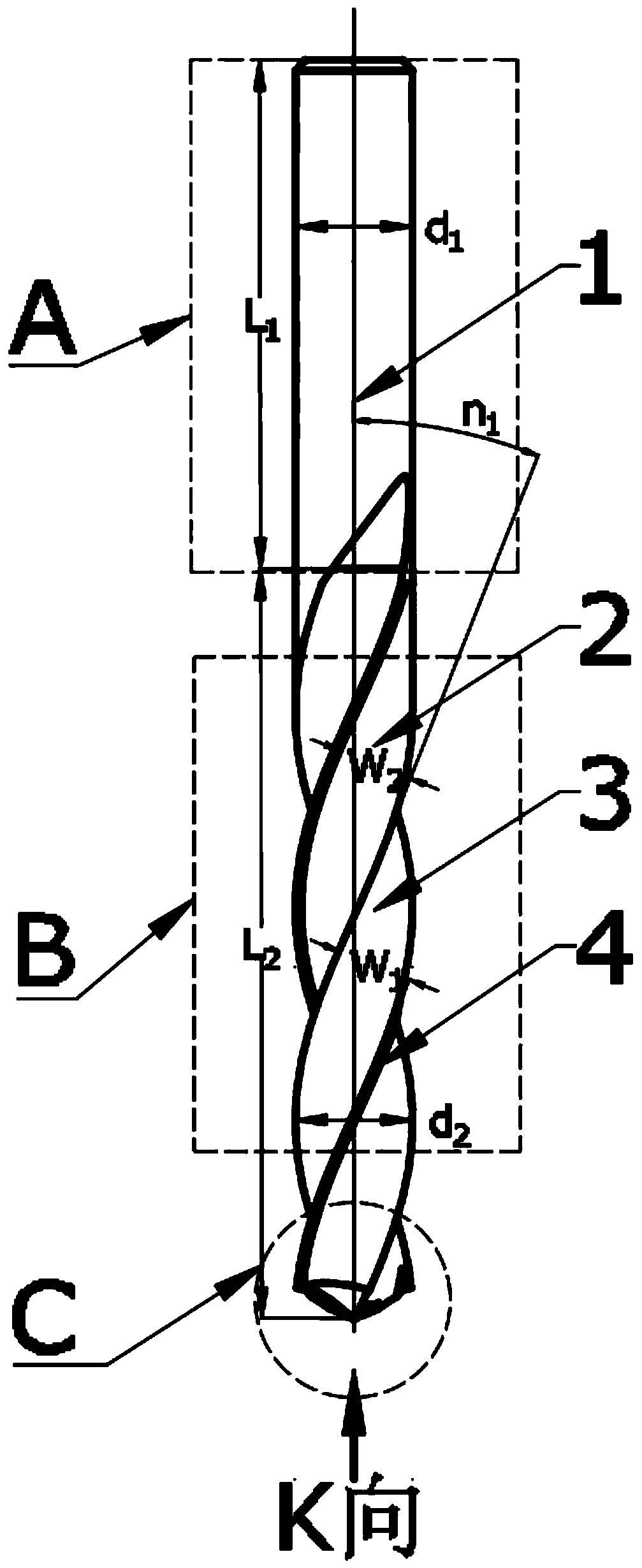

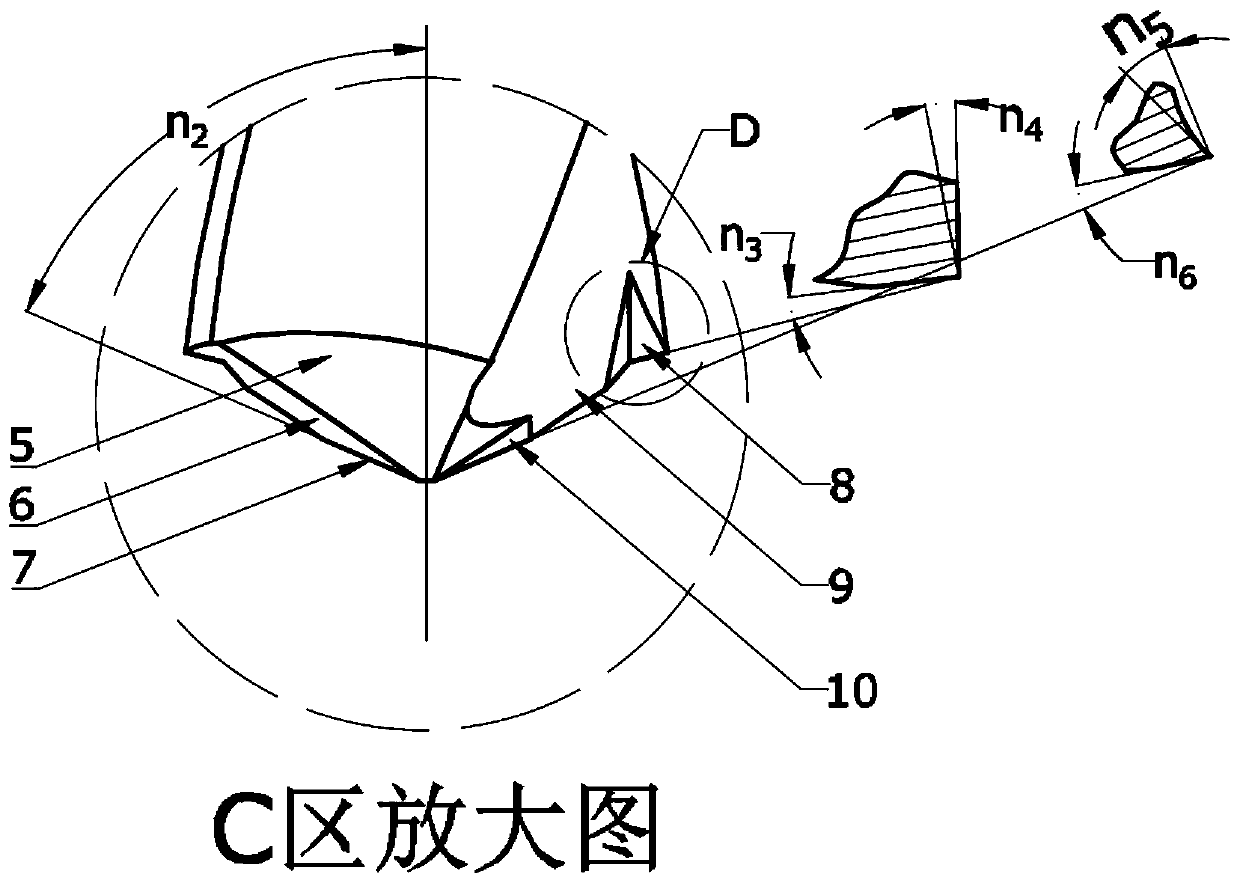

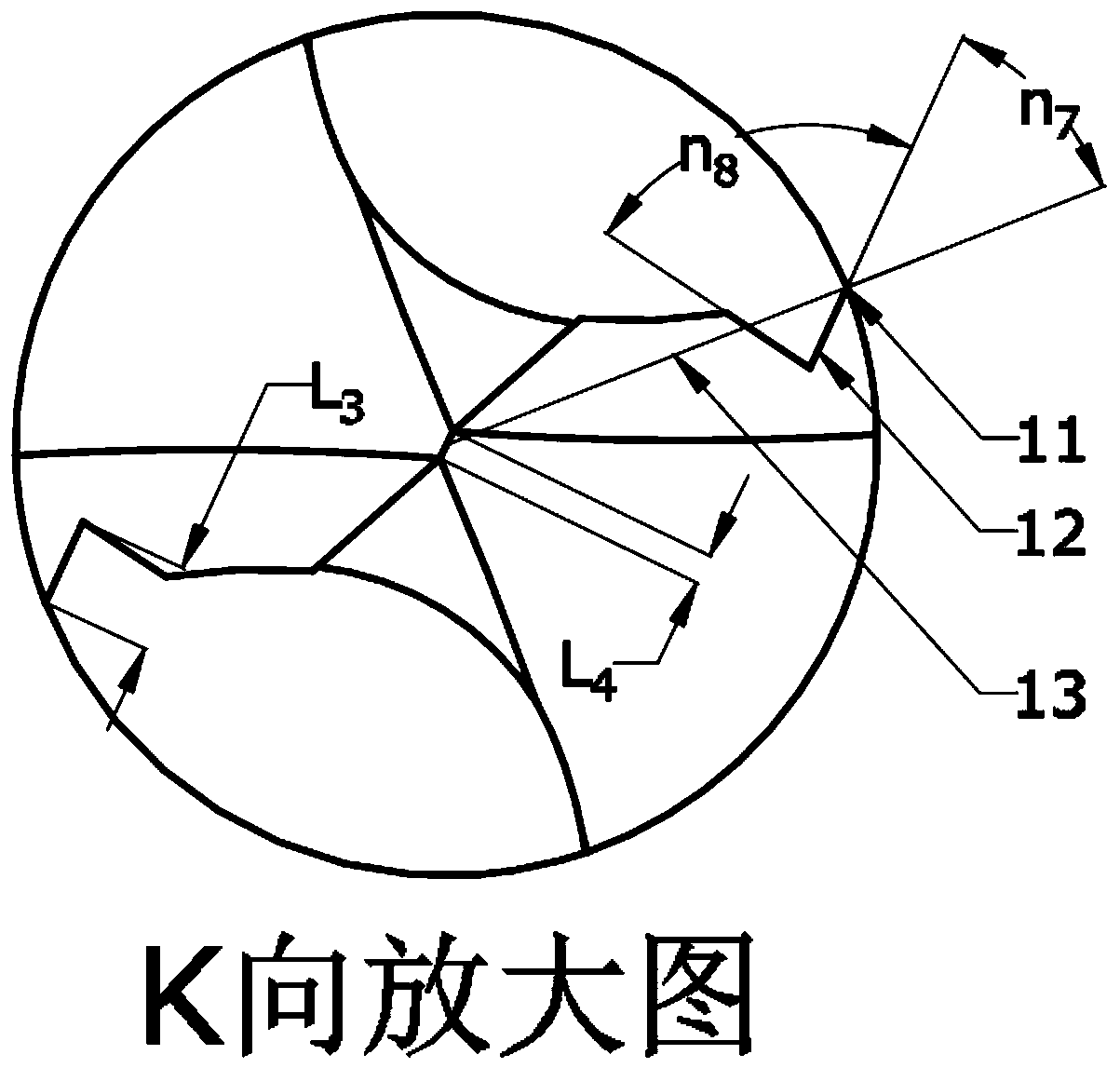

[0015] like figure 1 , figure 2 , image 3 As shown, the drill bit with edge groove structure of the present invention is composed of three parts: the shank area A of the tool clamping part, the minor cutting edge area B of the main body part of the drill bit, and the tool nose area C of the main cutting part of the drill. Generally, the secondary cutting edge area B of the drill has two chip flutes 3 and two edge backs 2, and there are secondary cutting edges 4 on the edge back 2, and the chip flute width W 1 0.8-0.9 times the tool diameter d 2 , blade width W 2 2.5-3.4mm; the angle n formed by the flute 3 and the tool axis 1 1 30°-45°. Tool diameter d 2 and cutting edge length L 2 The length L of the tool holding part can be determined according to the diameter and depth of the drilled hole 1 It can also b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com