Impact-resistant interval hard alloy saw and manufacturing method thereof

A cemented carbide and impact-resistant technology, which is used in tool manufacturing, manufacturing tools, metal sawing equipment, etc. , long service life and suitable chip amount

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

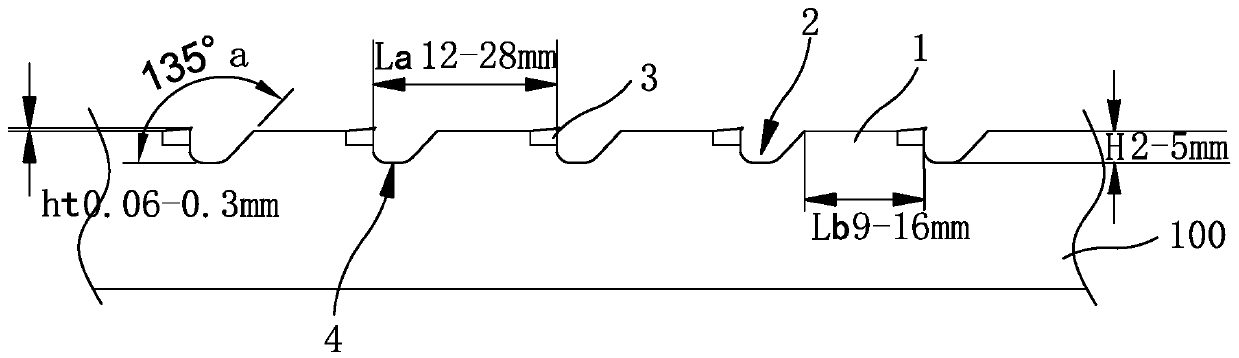

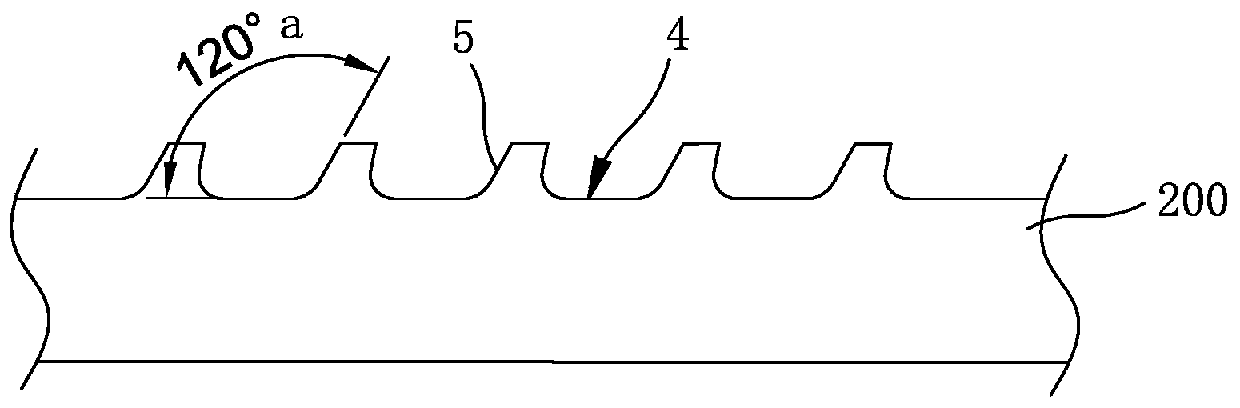

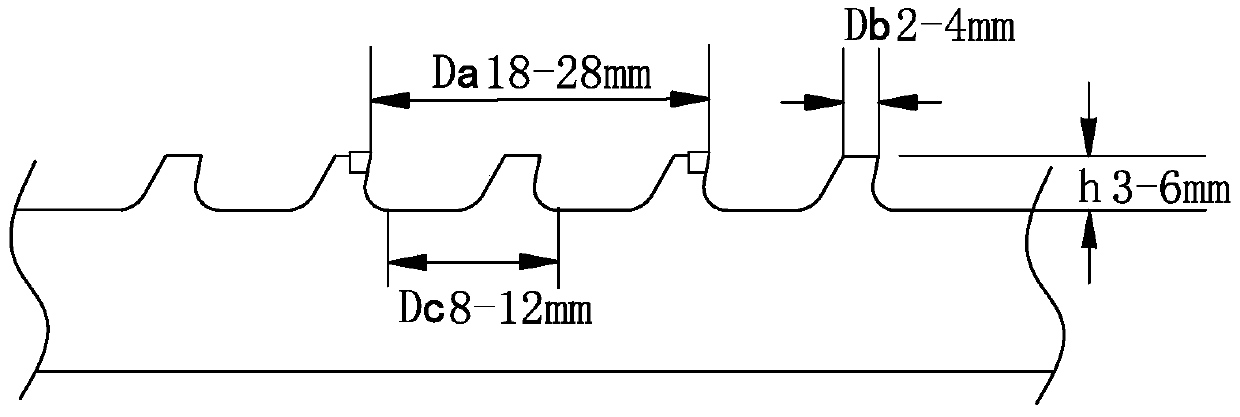

[0023] Now in conjunction with the accompanying drawings, the structure of the present invention will be further described. Such as Figure 1-Figure 4 As shown, the body of the cemented carbide saw is a spring steel sheet, the tip of the sawtooth 1 of the spring steel sheet is provided with a tooth tip 3, and the tooth tip is a hard alloy directly welded with tempered resistance welding at high temperature, and the adjacent There are formed saw grooves 2 between the saw teeth, the tooth root 4 at the bottom of the saw groove is the bottom platform of different lengths, the top of the saw tooth is the top platform, and the tooth back 5 at the rear of the saw tooth is set obliquely; the tooth tip is 1-3mm The square hard alloy welding block, the tip of the tooth is provided with a two-stage back angle 7 and a warping angle 6 that are tilted upward and outward. The angle c between the plane of the sawtooth top and the top is 12-20 degrees, the length of the warped angle is 0.12-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com