Control method and control device for etching before CVD synthetic diamond growth

A technology of synthetic diamond and control method, which is applied in the field of etching control method and control device before the growth of CVD synthetic diamond, which can solve the problems of wasting manpower, unreliability, and equipment can not grasp the specific time of etching, so as to save time and cost , improve quality, and avoid inefficient production activities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

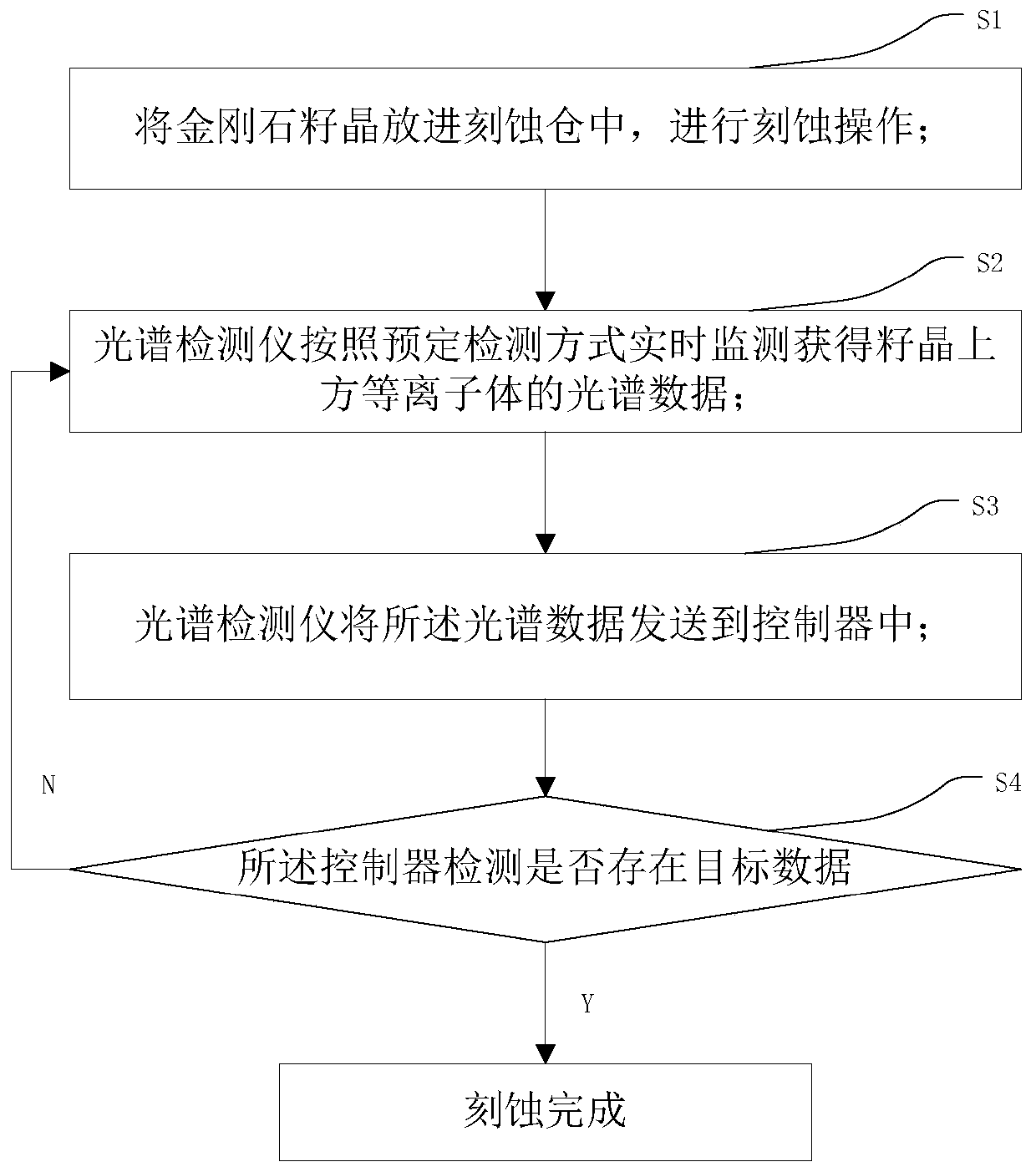

[0035] Please focus on figure 1 , the present invention provides a method for controlling etching before the growth of CVD synthetic diamond, comprising the steps of:

[0036] S1. Put the diamond seed crystal into the etching chamber for etching operation;

[0037] S2. The spectral detector obtains the spectral data of the plasma above the seed crystal by real-time monitoring according to a predetermined detection method;

[0038] S3. The spectrum detector sends the spectrum data to the controller;

[0039] S4. The controller detects whether there is target data, if yes, the etching is completed; if not, execute step S2.

[0040] Specifically, the etching chamber may be an etching chamber specially used for etching the surface of the diamond seed crystal, or a synthesis chamber for synthesizing diamond. When using the synthesis chamber, after determining the etching end point , that is, after the etching is completed, the normal diamond growth step can be started. The etch...

Embodiment 2

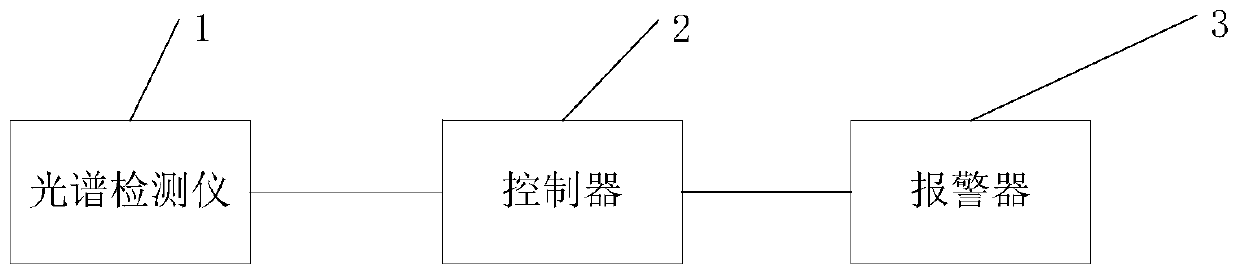

[0060] see figure 2 , a CVD synthetic diamond pre-growth etching control method applying the CVD synthetic diamond pre-growth etching device, comprising: a spectrum detection 1 and a controller 2;

[0061] The spectral detector 1 is used to detect the spectral data of the plasma above the seed crystal obtained during the etching process of the diamond seed crystal, and transmit the spectral data to the controller; the spectral detector 1 is preferably a plasma emission spectrometer.

[0062] The controller 2 is configured to integrate the electronic data and detect whether there is target data.

[0063] Specifically, as a preferred solution, the controller has a memory, and the memory stores the target data;

[0064] The target data is a change in the detected target spectral position exceeding a predetermined difference;

[0065] The target spectral position includes: a carbon atom peak at 437nm or 493nm, and a carbon molecule peak at 558nm.

[0066] Specifically, as a p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com