High-density carbon fiber needled felt and preparation method thereof

A technology of carbon fiber and needle-punched felt, applied in the field of needle-punched felt, which can solve the problems of difficult preparation, easily damaged needles, and difficulty in forming high-quality high-density carbon fiber needle-punched preforms, and achieve excellent mechanical properties and sliding resistance The effect of increase and decrease in thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

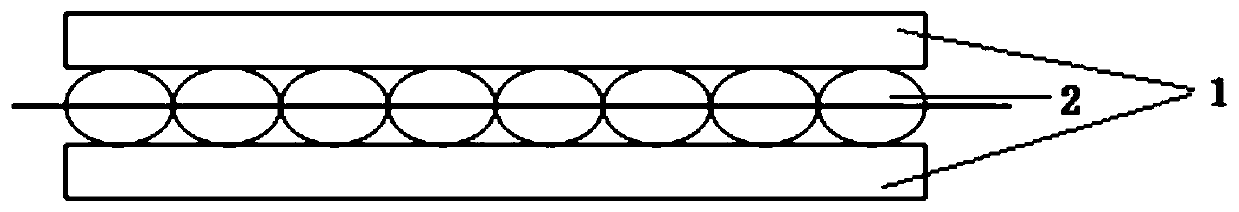

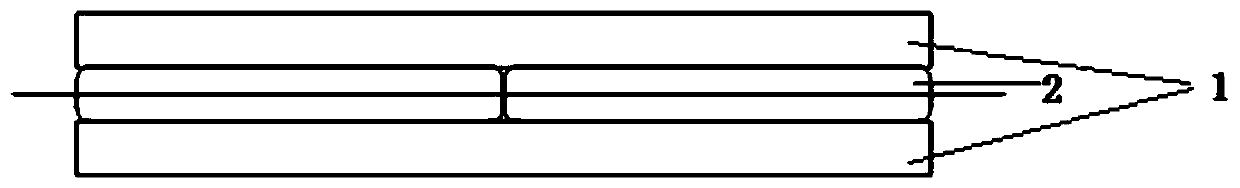

[0029] A high-density carbon fiber needle-punched preform (needle felt), the volume density of the carbon fiber needle-punched preform is 0.8g / cm 3 , the thickness is 4mm. The acupuncture prefabricated body is composed of 10 structural units, and each structural unit is composed of 1 layer of carbon fiber mesh and 1 layer of carbon fiber spread cloth, wherein the surface density of the carbon fiber mesh is 80g / m 2 , the surface density of the carbon fiber spread cloth is 240g / m 2 .

[0030] Prepare the carbon fiber preform as follows:

[0031] (1) prepare carbon fiber widening yarn;

[0032] After the 18K carbon fiber passes through the constant temperature zone with a temperature of 80°C at a speed of 20 m / min, it passes through the compressed air injection zone and the vacuum adsorption zone in turn to form a 10mm widened carbon fiber belt, and then spray resin to shape it. The compressed air injection speed is 10m / s, and the distance between the carbon fiber and the inj...

Embodiment 2

[0038] A high-density carbon fiber needle-punched preform (needle felt), the volume density of the carbon fiber needle-punched preform is 0.6g / cm 3 , the thickness is 20mm. The needle-punched prefabricated body is composed of 30 structural units, and each structural unit is composed of 2 layers of carbon fiber mesh tires and 2 layers of carbon fiber widened unidirectional fabrics. The area density of the carbon fiber mesh tires is 40g / m 2 , the surface density of the carbon fiber spread cloth is 60g / m 2 .

[0039] Prepare the carbon fiber preform as follows:

[0040] (1) prepare carbon fiber widening yarn;

[0041] After the 3K carbon fiber passes through the constant temperature zone with a temperature of 110°C at a speed of 15 m / min, it passes through the compressed air injection zone and the vacuum adsorption zone in turn to form a 10mm widened carbon fiber belt, and then sprays resin to shape it. The compressed air injection speed is 15m / s, and the distance between the...

Embodiment 3

[0047]A high-density carbon fiber needle-punched preform (needle felt), the volume density of the carbon fiber needle-punched preform is 0.8g / cm 3 , the thickness is 6mm. The acupuncture prefabricated body is composed of 8 structural units, and each structural unit is composed of 2 layers of carbon fiber mesh tires and 2 layers of carbon fiber expanded cloth, wherein the area density of the carbon fiber mesh tires is 100g / m 2 , the surface density of the carbon fiber spread cloth is 200g / m 2 .

[0048] Prepare the carbon fiber preform as follows:

[0049] (1) prepare carbon fiber widening yarn;

[0050] After the 24K carbon fiber passes through the constant temperature zone with a temperature of 80°C at a speed of 8 m / min, it passes through the compressed air injection zone and the vacuum adsorption zone in turn to form a 20mm widened carbon fiber belt, and then sprays resin to shape it. The compressed air injection speed is 25m / s, and the distance between the carbon fiber...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Areal density | aaaaa | aaaaa |

| Bulk density | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com