Corrugated steel plate combined frame structure system and application

A technology of frame structure and corrugated steel plate, applied in the direction of floor slab, building components, building structure, etc., can solve the problems of waste of manpower and material resources, complicated construction, poor economy, etc., to save cost, improve indoor space utilization rate, and good deformation performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

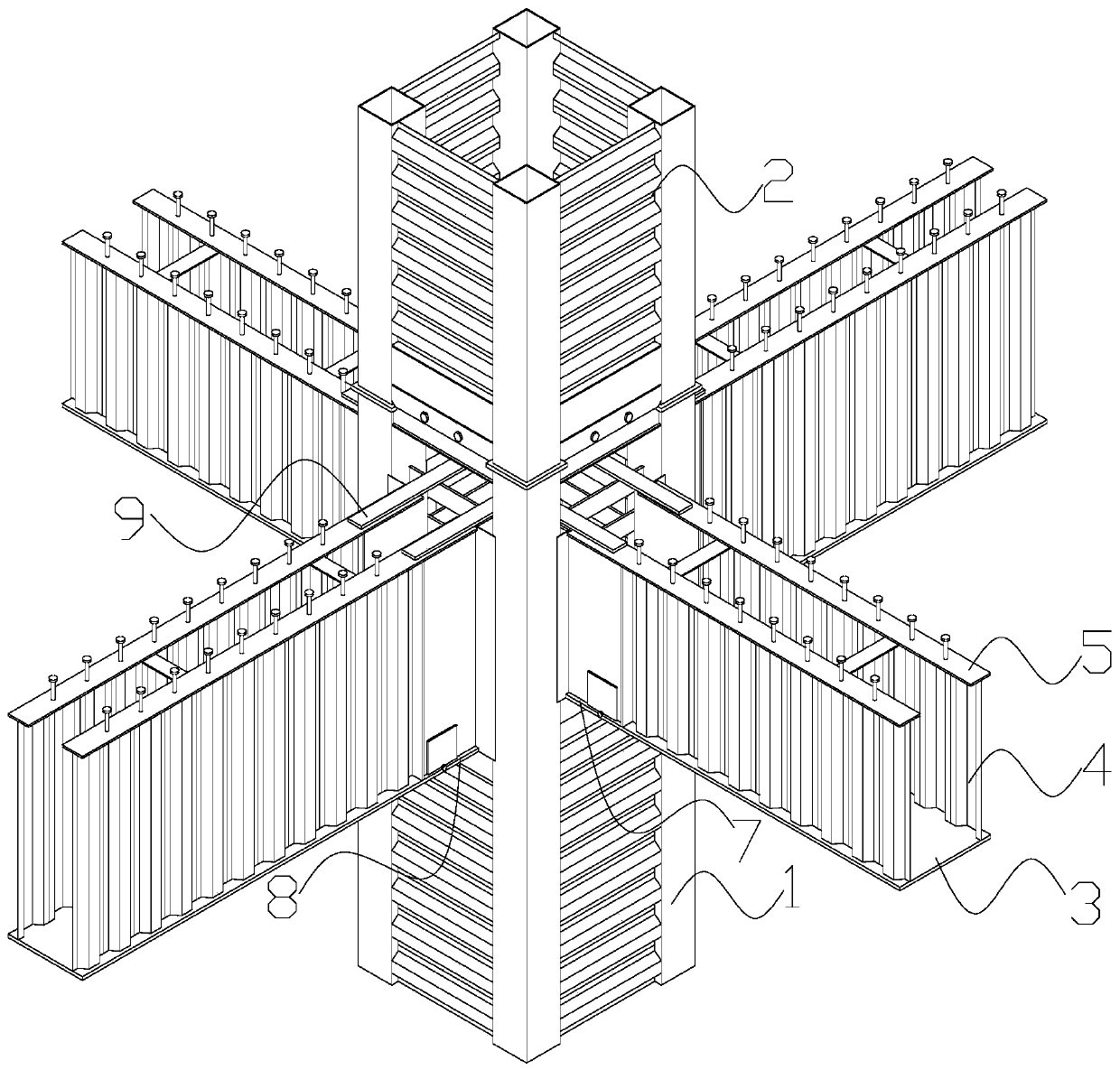

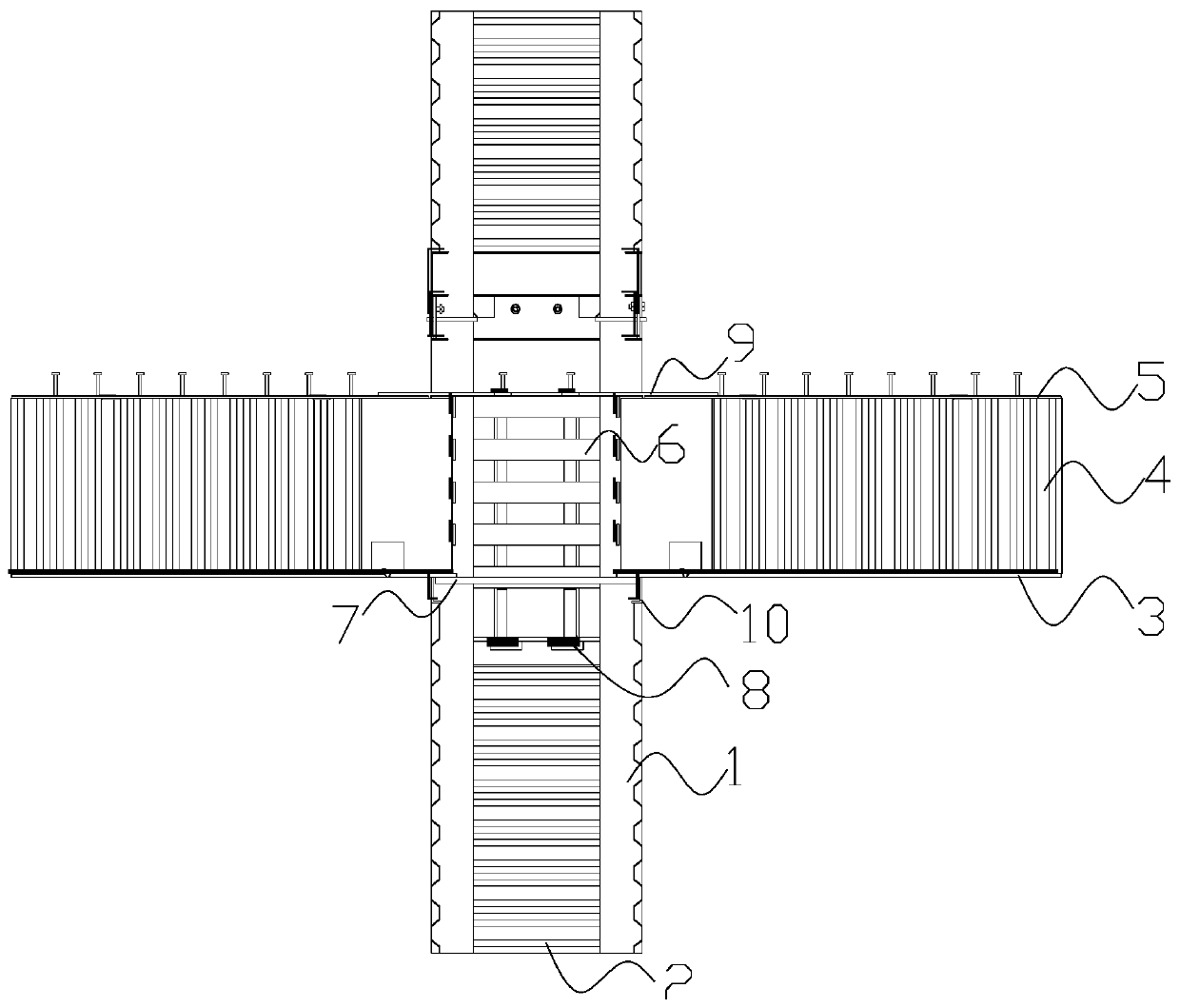

[0039] The technical solution adopted by the present invention will be further described below in combination with schematic diagrams.

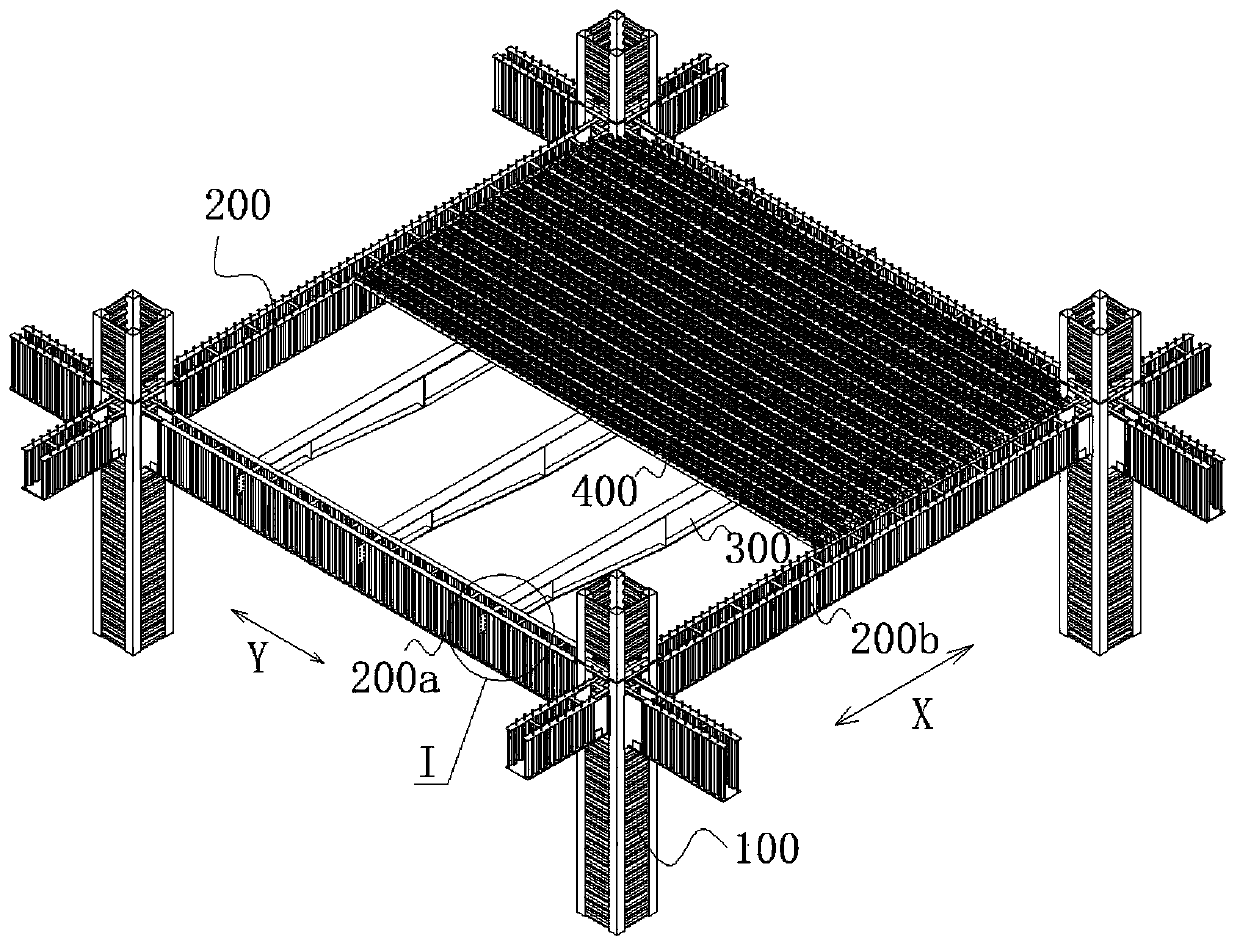

[0040] The invention provides a corrugated steel composite frame structure system, which is composed of carapace columns 100 , carapace beams 200 , H-shaped steel secondary beams 300 , and formwork-free and support-free floor decks 400 . exist figure 1 A schematic diagram of the local structure of the corrugated steel plate composite frame structure system is given in figure 1 The direction shown by arrow X is defined as direction one, and the direction shown by arrow Y is defined as direction two. Direction one can be understood as the horizontal expansion direction of the system, and direction two is understood as the vertical expansion direction of the system. The height direction of is the height expansion direction of the system.

[0041] In the present invention, see figure 1, the carapace beam 200 includes the main carapace beam 200...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com