Vehicle system and method for injecting aqueous solution in the combustion chamber of the internal combustion engine

A vehicle system and aqueous solution technology, applied in the field of vehicle systems, can solve the problems of impractical use of UV radiators, high cost, and difficult replacement operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

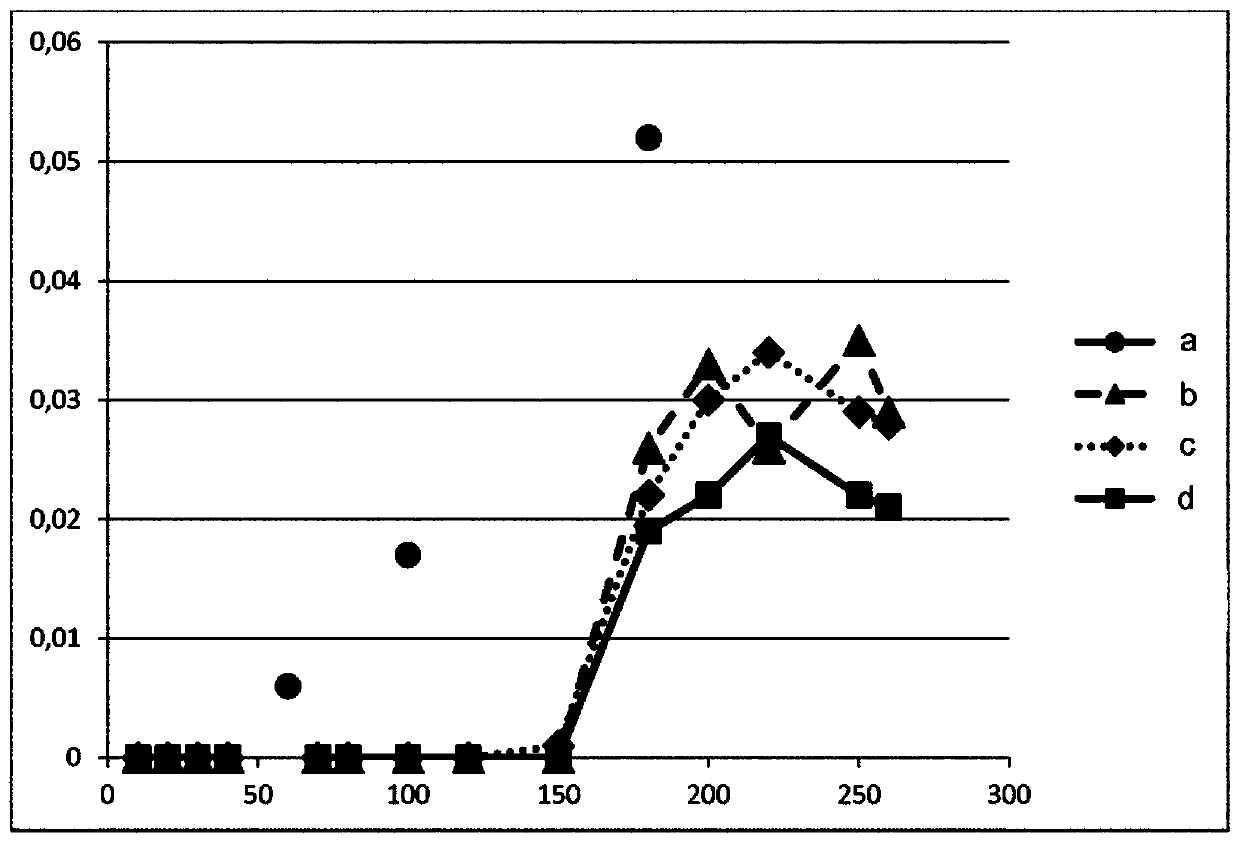

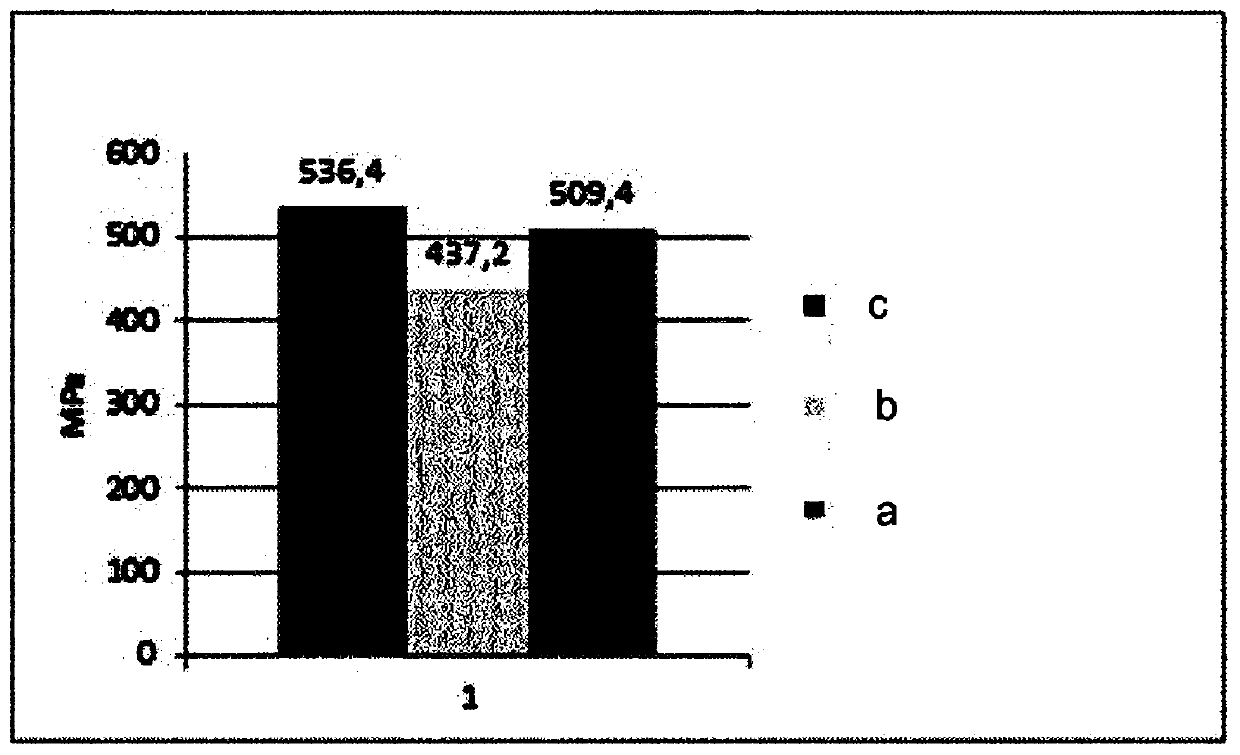

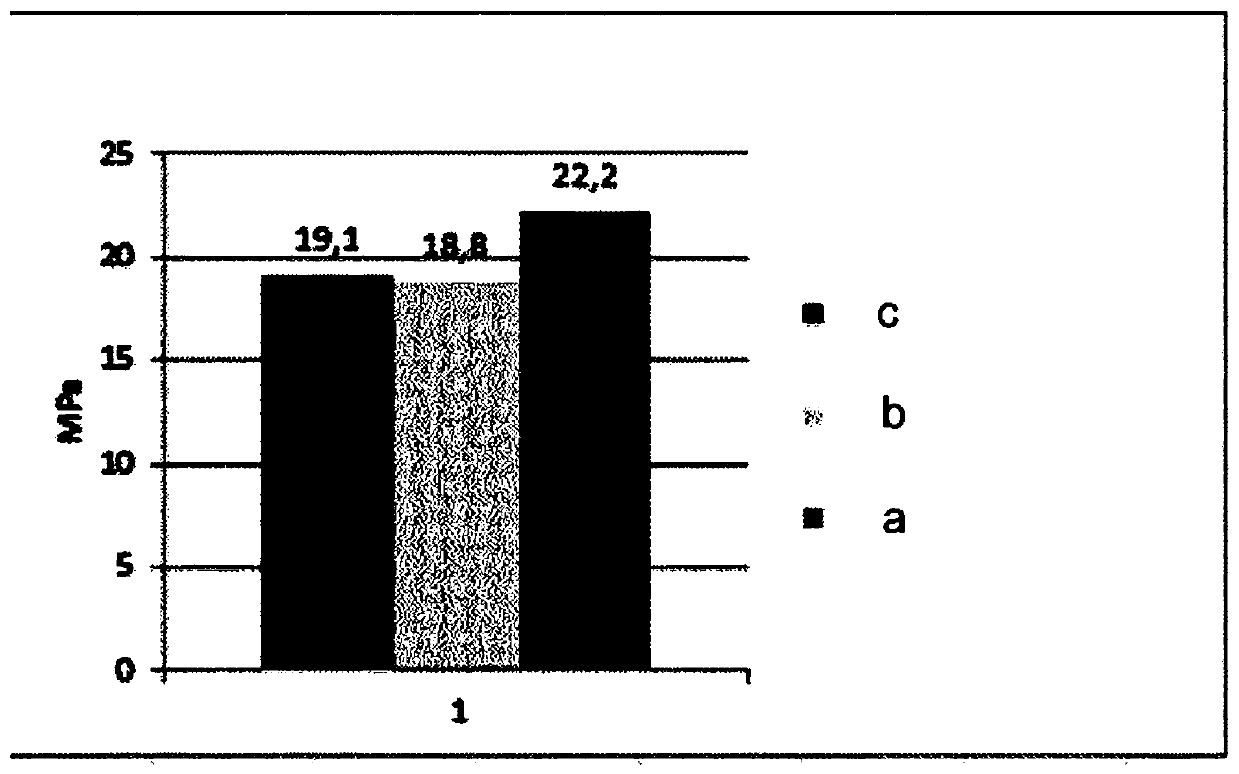

[0068] In order to reproduce the effect of bacterial contamination in the tank and to investigate the antibacterial effect of adding an antimicrobial metal compound to the wall of the tank, the following experiments were performed.

[0069] 4 water storage tanks were tested:

[0070] Reference tank a (control) made of high-density polyethylene (HDPE) without antimicrobial metal compounds;

[0071] tank b made of HDPE containing 0.2% by weight of an antimicrobial metal compound of zinc which is zinc pyrithione;

[0072] Tank c made of HDPE containing 0.034 wt% of an antimicrobial metal compound of silver that is silver metal nanoparticles;

[0073] Tank d made of HDPE containing 0.1% by weight of an antimicrobial metal compound of zinc, zinc pyrithione, and 0.017% by weight of an antimicrobial metal compound of silver are silver metal nanoparticles.

[0074] All tanks tested were made by injection moulding, and formed from 2 half-shells welded together by hot plate. It has ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com