Compound crystallization device, compound preparation system and compound crystallization process

A crystallization device and preparation system technology, which is applied to the general layout of the crystallization device, solution crystallization, crystallization separation, etc., can solve problems such as uneven heat release, too fast local crystallization, and excessive crystal particle size deviation, so as to improve the finished product The effect of improving quality, improving work efficiency, and shortening the overall time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

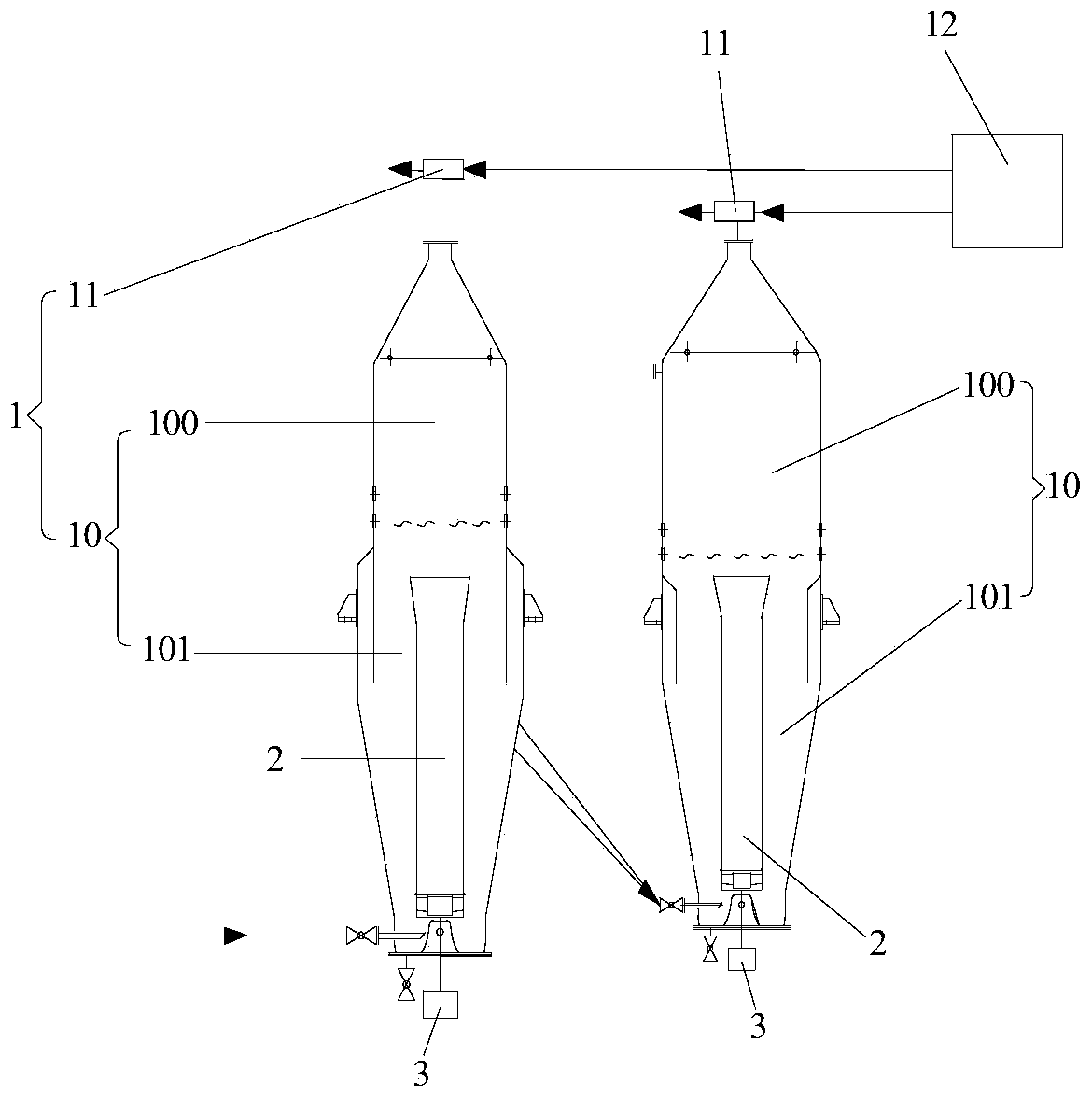

[0048] like figure 1 As shown, the compound crystallization device provided in this embodiment includes a multi-stage cooling unit 1, each cooling unit 1 includes a cooling chamber 10, and a refrigeration module 11 is arranged in the cooling chamber 10, and the refrigeration module 11 is used to make the cooling chamber 10 The compound solution is maintained within the set temperature range. The cooling chambers 10 in the multi-stage cooling unit 1 communicate in sequence. In any adjacent two-stage cooling unit 1, the refrigeration module 11 of the latter-stage cooling unit 1 is used to make the temperature of the cooling chamber 10 of the cooling unit 1 of this stage lower than that of the cooling chamber 10 of the cooling unit 1 of the previous stage. temperature.

[0049] When using the compound crystallization device to crystallize a crystallizable compound solution, the compound solution can be sent into the cooling chamber 10 in the first-stage cooling unit 1 . The ab...

Embodiment 2

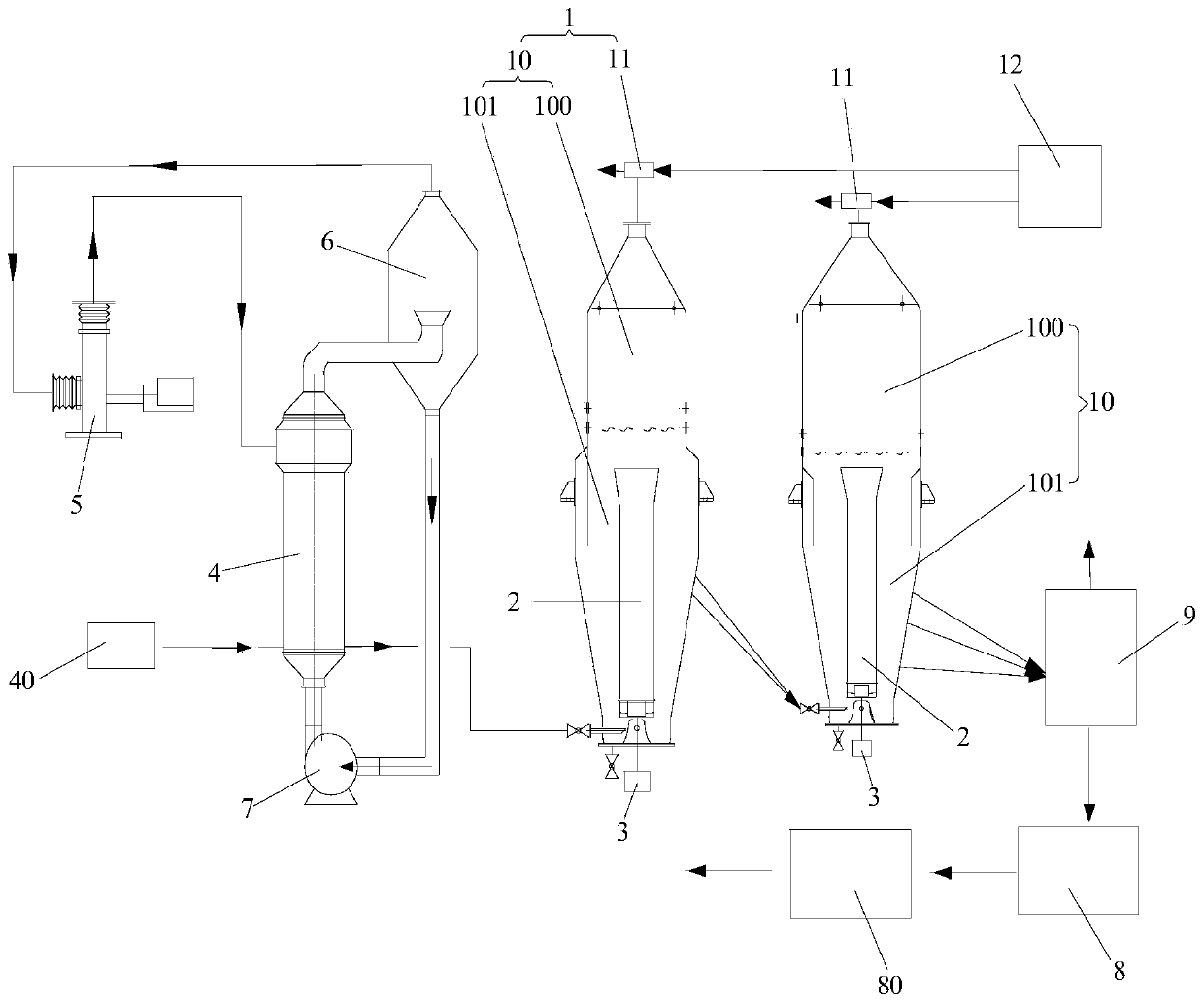

[0092] like figure 2 As shown, the compound preparation system provided in this example includes the solution concentration device and the compound crystallization device in Example 1. The solution concentration device includes a heating chamber 4 and a heating module 5 , and the heating module 5 is used to heat the moisture in the compound solution in the heating chamber 4 . The cooling chamber 10 in the cooling unit 1 of the first stage in the compound crystallization device communicates with the heating chamber 4 .

[0093] The solution concentration device can use the heating module 5 to heat and evaporate the moisture in the compound solution in the heating chamber 4, thereby increasing the concentration of the compound solution, so that the compound solution forms a saturated solution, or even a supersaturated solution, which is used for the next step. The device prepares the compound solution for crystallization.

[0094] In this embodiment, it is preferable to conce...

Embodiment 3

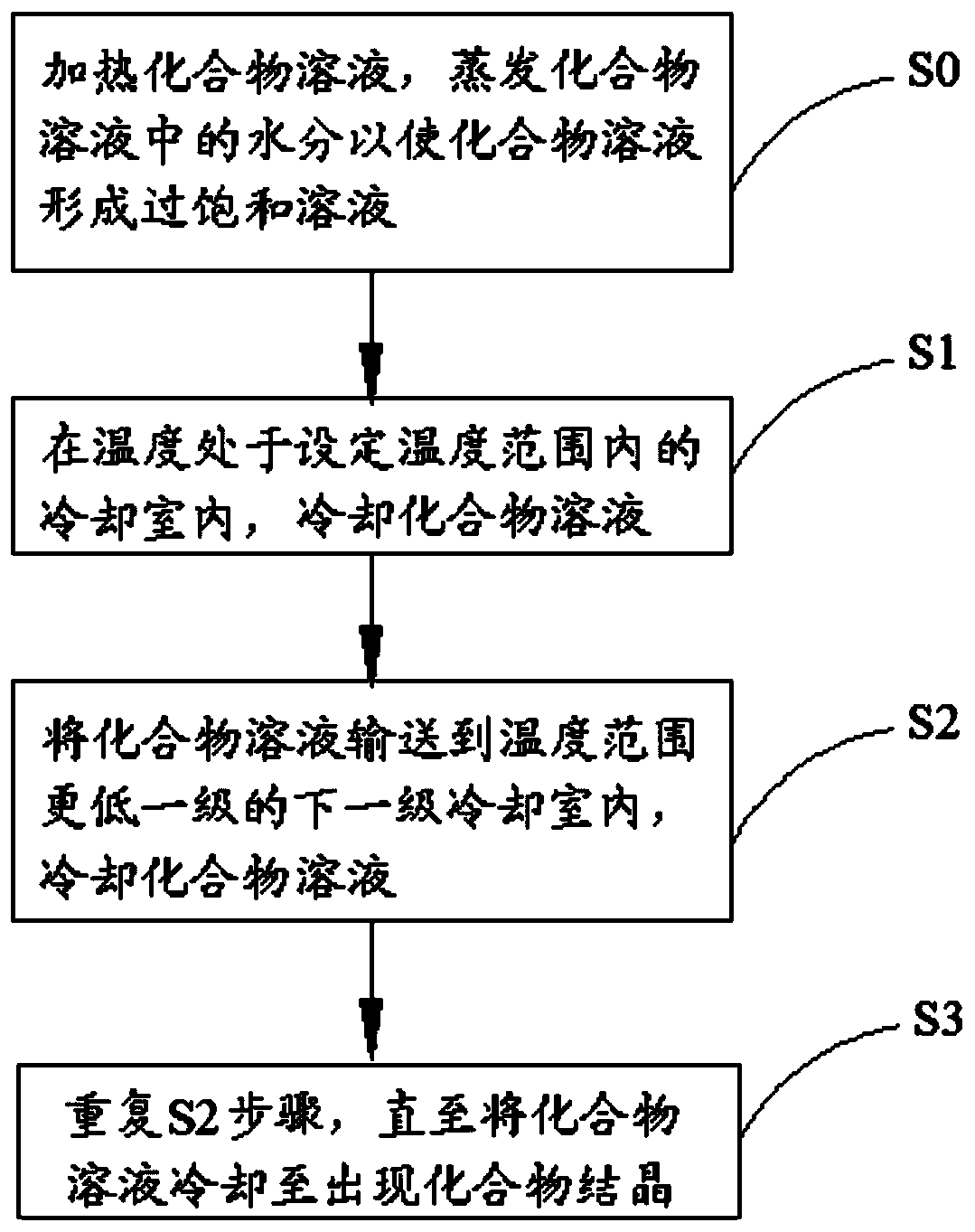

[0113] like image 3 As shown, the compound crystallization process provided in this embodiment includes:

[0114] Step S1: cooling the compound solution in a cooling chamber whose temperature is within a set temperature range;

[0115] Step S2: transporting the compound solution to a next-level cooling chamber with a lower temperature range to cool the compound solution;

[0116] Step S3: repeat step S2 until the compound solution is cooled until crystallization of the compound occurs.

[0117] The compound crystallization process provided in this example can use the compound crystallization device in Example 1 to sequentially implement the above steps S1, S2 and S3, and then crystallize the compound in the compound solution.

[0118] Further, the compound crystallization process provided in this example can also use the vacuum pump in the compound crystallization device in Example 1 to exhaust the gas in the cooling chamber in step S1 and step S2, so as to reduce the air p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com