A construction method for a continuous wall of interlocking piles combined with self-protecting drill pipe and steel casing

A construction method and technology of steel casing, applied in drill pipe, sheet pile wall, drill pipe, etc., can solve the problems of hole channeling, easy generation of cold seams, leakage, etc., to prevent hole channeling, avoid inconsistent temperature difference, transmission High thermal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

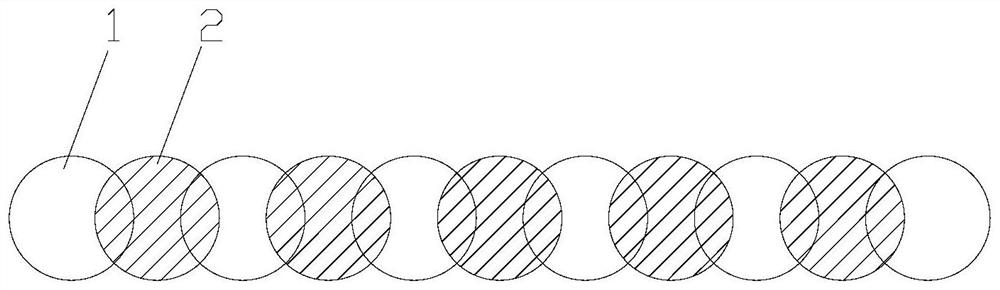

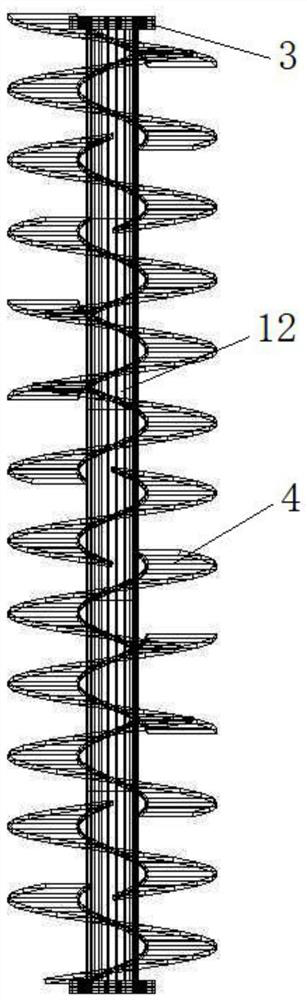

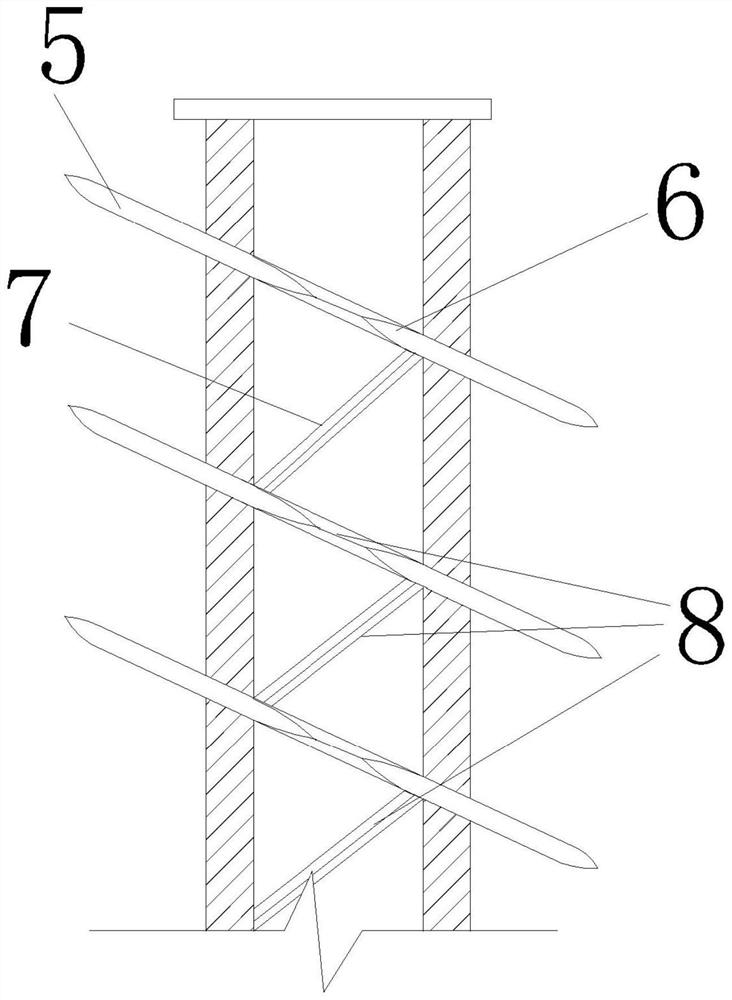

[0040] Such as figure 2 , image 3 and Figure 4 As shown, the present invention also discloses a self-protecting drill rod including a central tube 12, and flanges 3 are arranged at both ends of the central tube; Spiral piece 4. The helical blade includes an outer biting vane 5 located on the outside and an inner shearing vane 6 protruding into the body of the pipe. Multiple groups of the inner shearing pieces are connected together through the inner helical connecting piece 7; the two form a coherent and helically extending flow guide 8; the section of the inner helical connecting piece is tapered. The helical piece includes an inner cavity 11 extending from one side of the outer occlusal blade to one side of the inner shearing blade, the inner cavity is provided with a flow guide inner tube 9 with capillary holes, and both ends of the inner cavity are There is a copper shunt heat conduction sheet 10; a small amount of volatile ether solution is stored in the inner cavi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com