Wheel-shaft type energy saving beam-pumping unit

A technology of pumping units and beams, which is applied in the field of axle-type energy-saving beam pumping units, can solve the problems of potential safety hazards, high operating costs, and high management costs, and achieve improved utilization effects, reduced labor intensity, and reduced energy consumption Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

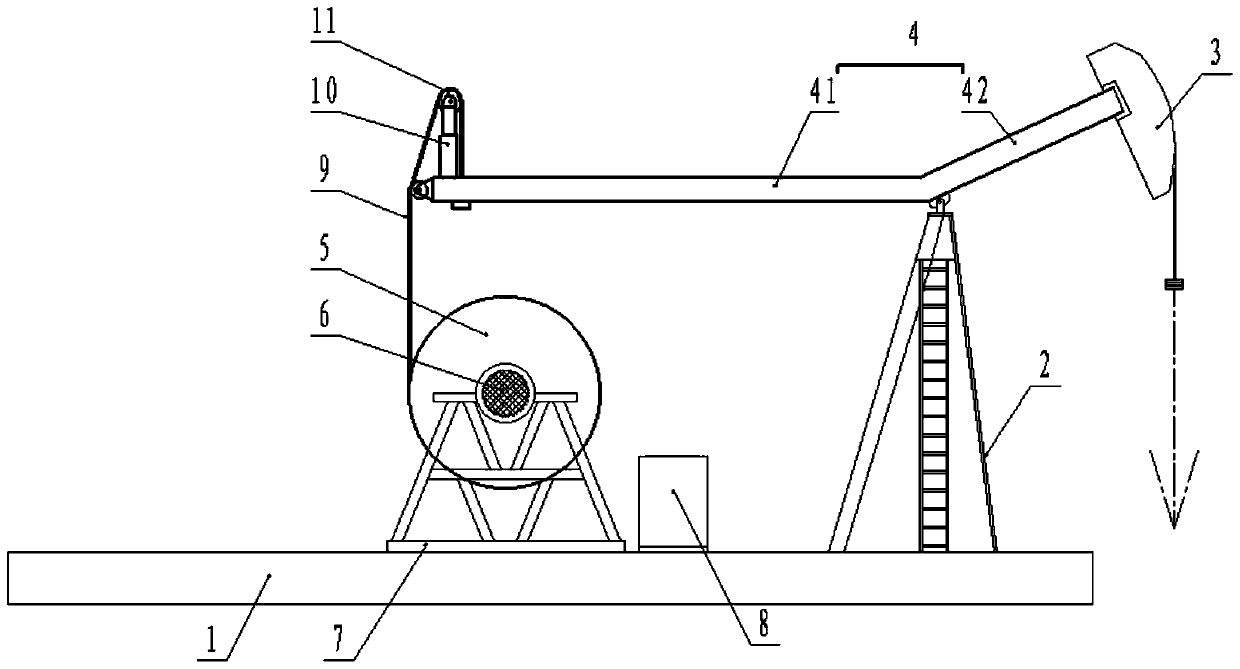

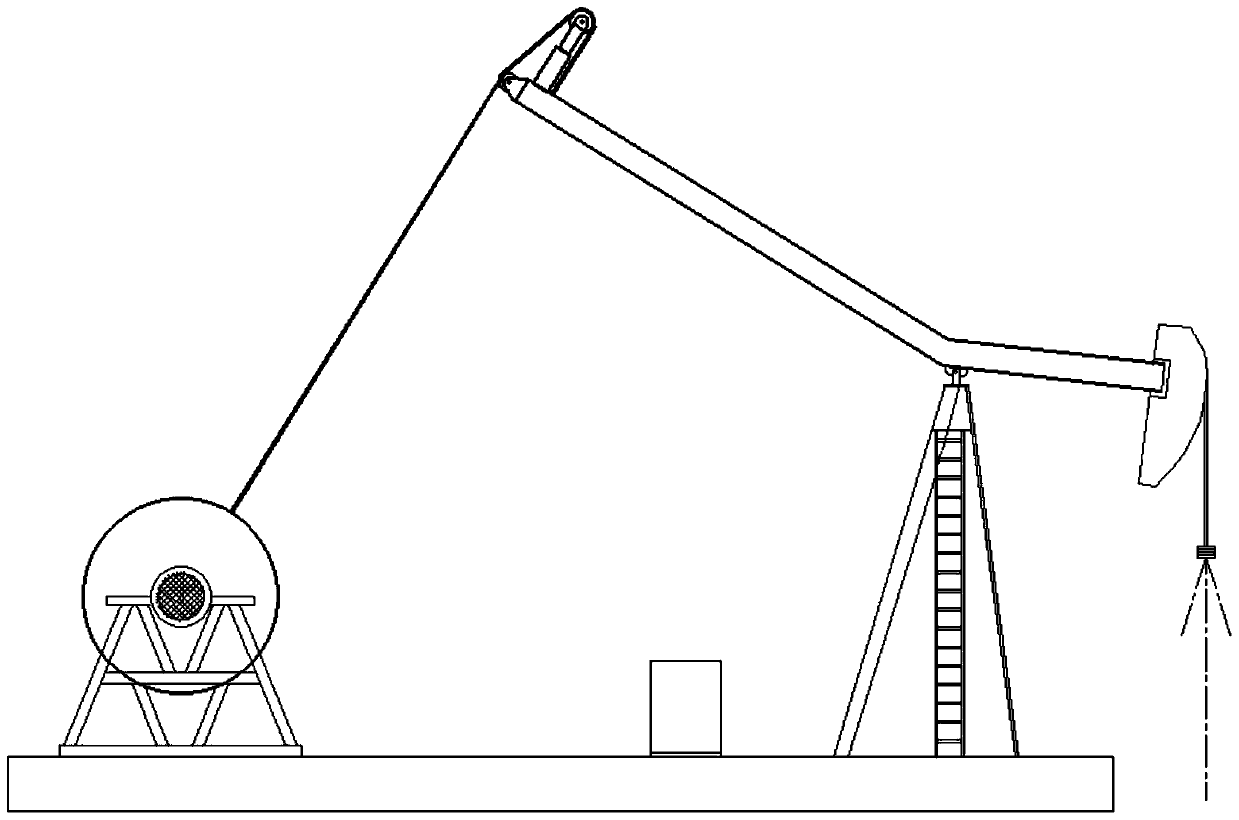

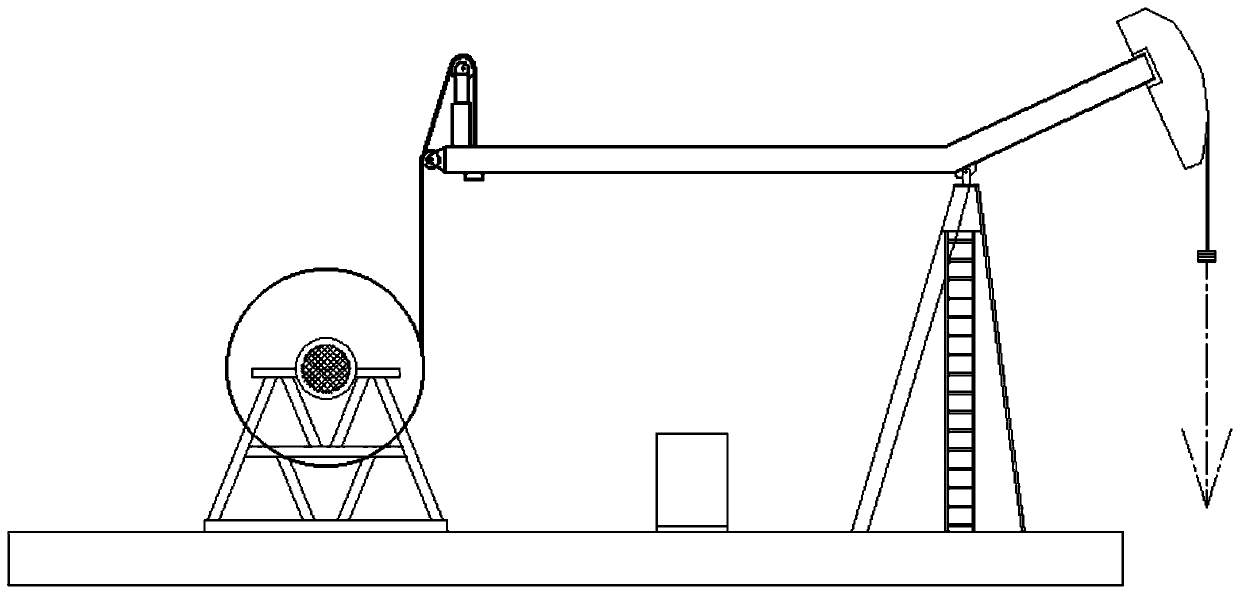

[0025] The present invention will be further described below in conjunction with accompanying drawing:

[0026] combined with Figure 1-6 , a wheel-shaft energy-saving beam pumping unit in this embodiment, comprising a base 1, a bracket 2, a donkey head 3, a beam 4 and a driving device, the bracket 2 is fixed on the base 1, and the beam 4 is hinged on the top of the bracket 2 , The donkey head 3 is installed on one end of the beam 4, and the other end of the beam 4 is connected with the driving device. The above are existing structures in the prior art, and will not be repeated here.

[0027] The innovation point of the present invention is:

[0028] The beam 4 includes two straight sections at an obtuse angle, which are respectively called the long section beam 41 and the short section beam 42 according to different lengths. On the premise of ensuring the stroke of the pumping unit, increasing the length of the long section beam 41 is reflected in the principle of leverage...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com