Construction method of crossing mining method tunnel by shield empty pushing

A construction method and technology for tunnel construction, applied in tunnels, tunnel linings, mining equipment, etc., can solve problems such as failure to rise, cement mortar backing up to the front of the cutter head, and overturning.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

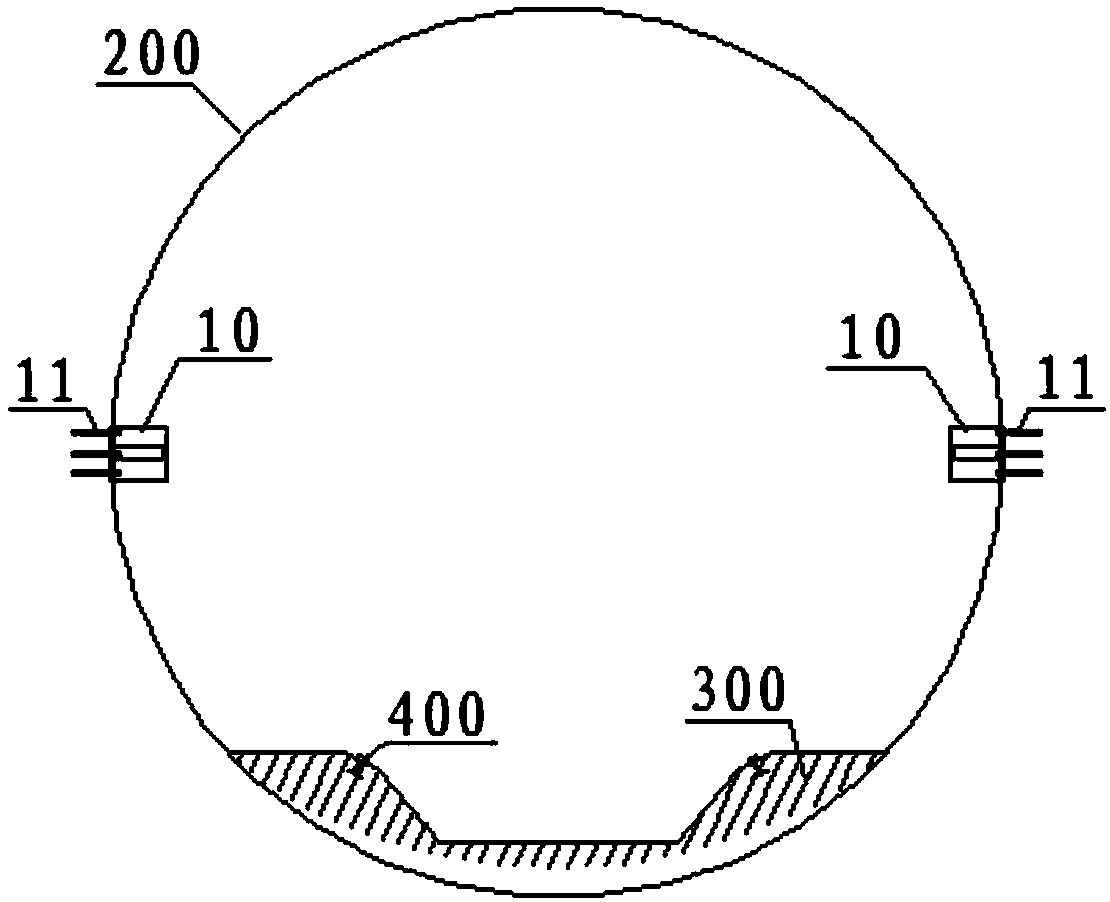

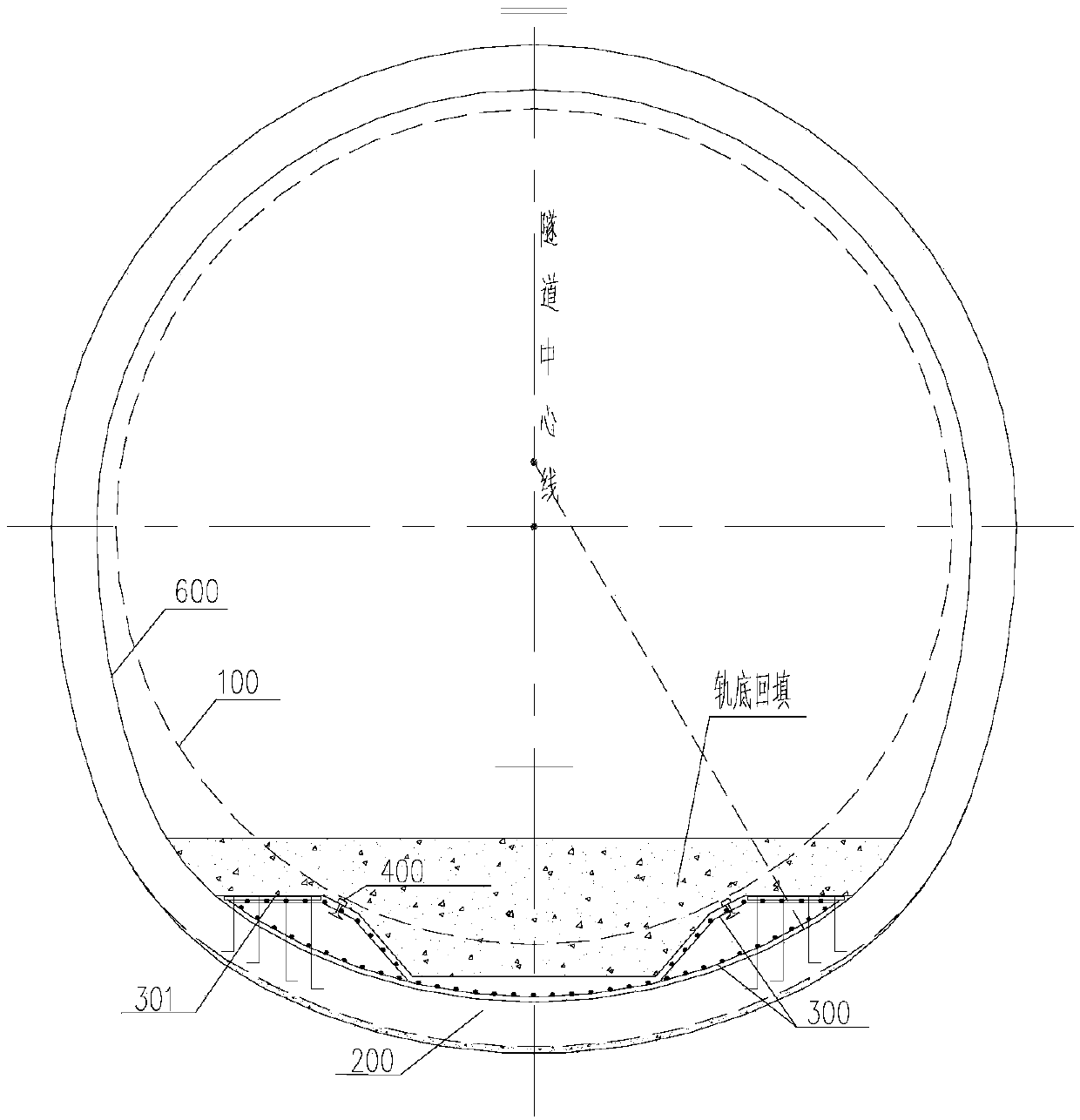

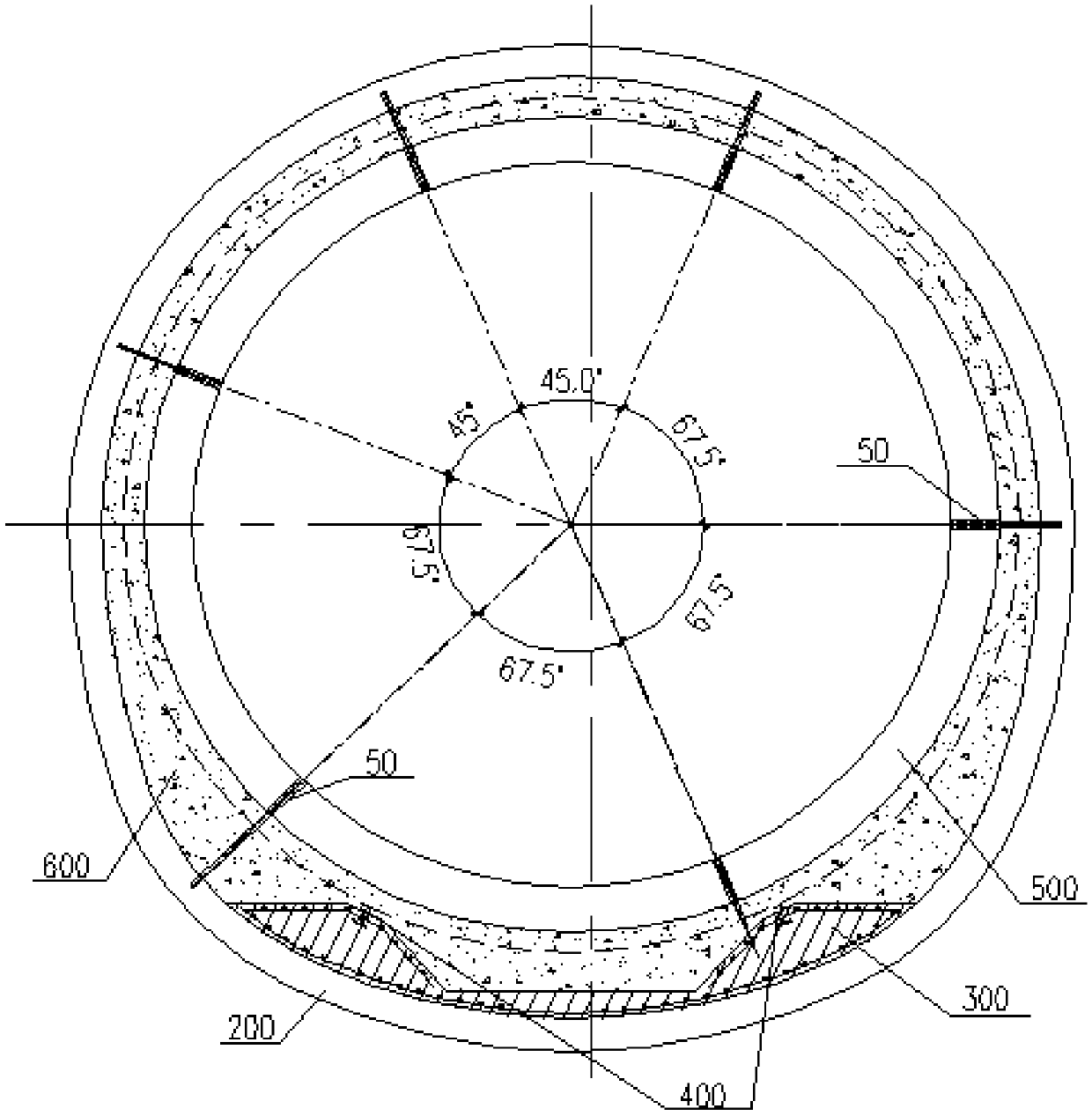

[0062] The present invention will be further described below in conjunction with accompanying drawing.

[0063] The construction method of shield tunneling through the mining method tunnel of the present invention is used for the construction of two subway station intervals, and the left and right lines are set in the two subway station intervals; section, the first shield section, the mining method tunnel section and the second shield section; an intermediate vertical shaft is set at the junction of the mining method tunnel section and the second shield section; the shield machine starts from the shield shaft at the end of the open cut section It is sent to the first shield section for normal excavation and received in the mine tunnel. Firstly, the shield is empty-pushed and assembled at the initial section of the mine tunnel, and then it is pulled through the subsequent section of the mine tunnel, and then in the middle shaft Receiving and hoisting; the shield machine normal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com