Goaf longitude and latitude filling method

A technology of goaf and latitude and longitude, applied in the direction of filling, mining equipment, earth cube drilling and mining, etc., can solve the problems of large investment in filling equipment, loss of coal resources, low construction efficiency, etc., and achieve low construction cost, low cost, and protection Aquifer Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

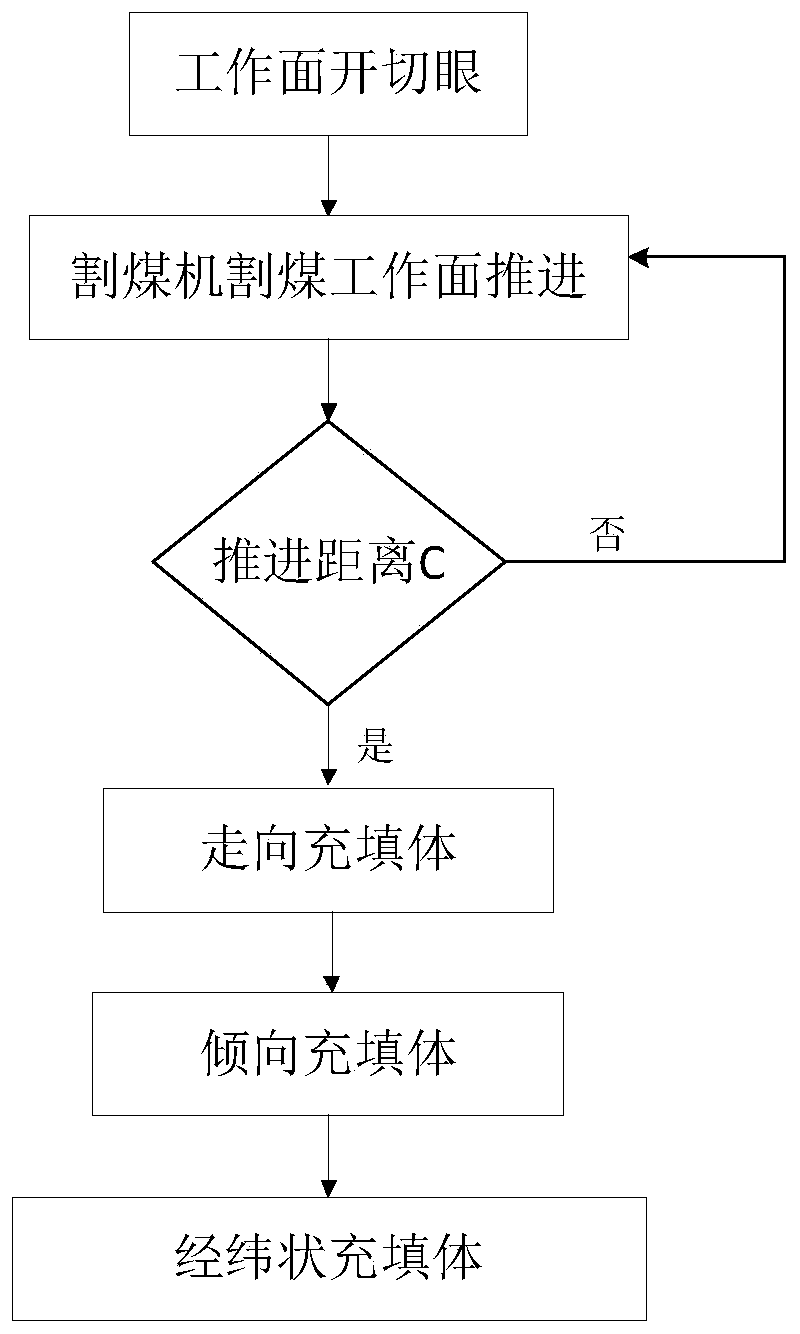

[0028] Due to the existing filling mining method, the filling construction operation is complicated and the filling cost is high; in order to simplify the filling operation steps, reduce the construction cost of the filling body, and ensure that the roof of the goaf does not collapse, so as to effectively control the surface subsidence and protect the aquifer. The recovery rate of coal resources; a method for filling the goaf in the shape of latitude and longitude is provided, and the steps include:

[0029] Step 1. Open the cutting hole on the working face, and the coal cutter stops cutting coal after every two knives of coal are cut obliquely.

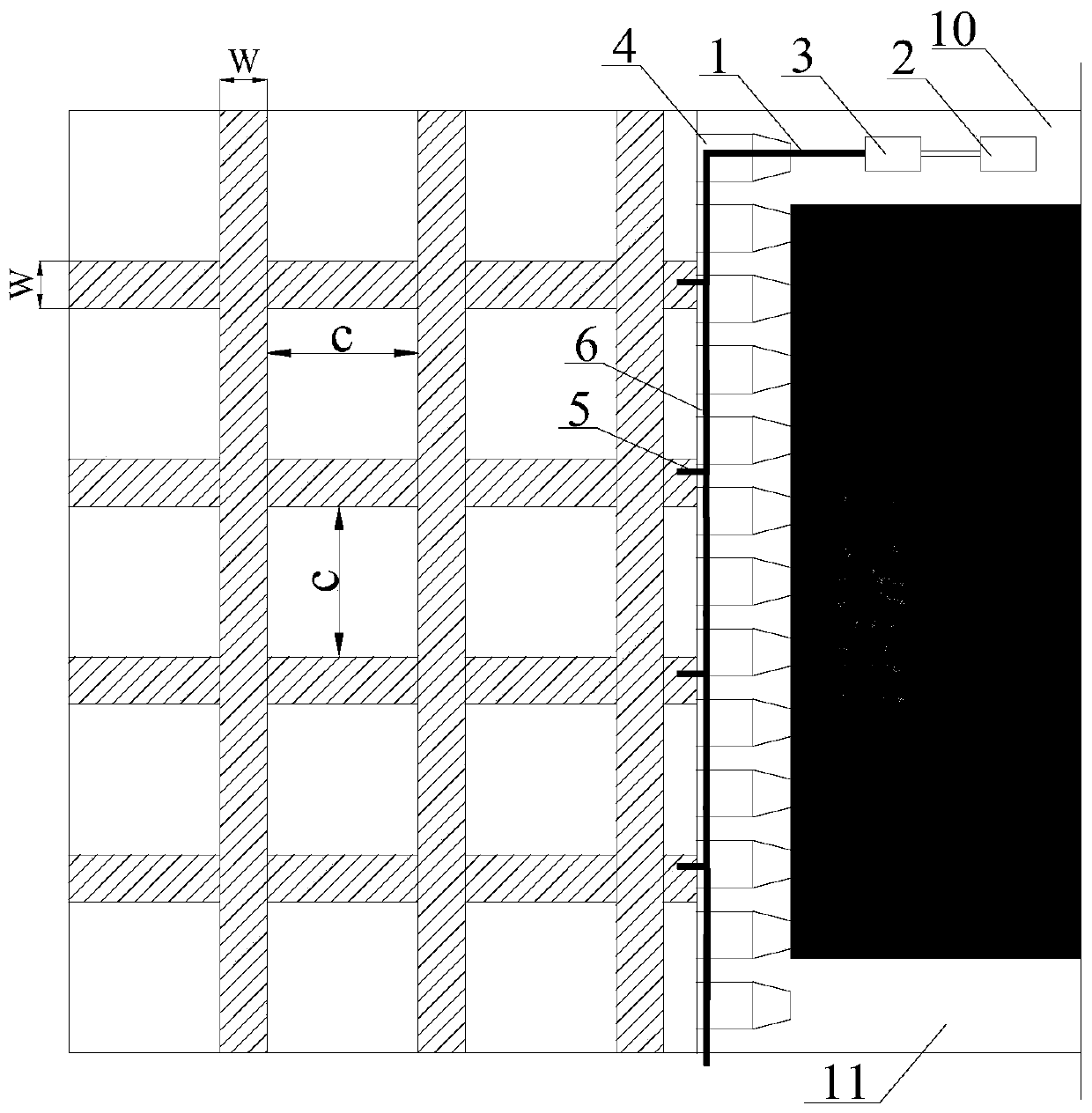

[0030] Step 2. Starting from the roadside of the mining roadway on both sides of the goaf, a filling body with a width of W is arranged along the direction of the working face at every interval c.

[0031] Step 3. The working face continues to advance, and the inclined filling body with a width of W is arranged along the working face...

Embodiment 2

[0038] A method for filling a goaf in a latitude and longitude shape, capable of filling in a goaf to form a latitude and longitude shape, ensuring that the roof of the goaf does not collapse, and effectively controlling surface subsidence. The steps include:

[0039] Step 1. Lay gangue paste conveying pipes in the transport leveling of the working face, and arrange filling pumps and mixers at the same time; then cut holes in the working face, and the coal cutter cuts coal every two knives and cuts obliquely before stopping coal cutting.

[0040] Step 2. Starting from the roadside of the mining roadway on both sides of the goaf, a filling body with a width of W is arranged along the direction of the working face at every interval c. Specifically, a strike filling space is arranged at regular intervals along the direction of inclination. The establishment of the space can be surrounded by a conventional filling and mining baffle structure. Filling can be arranged on both sides o...

Embodiment 3

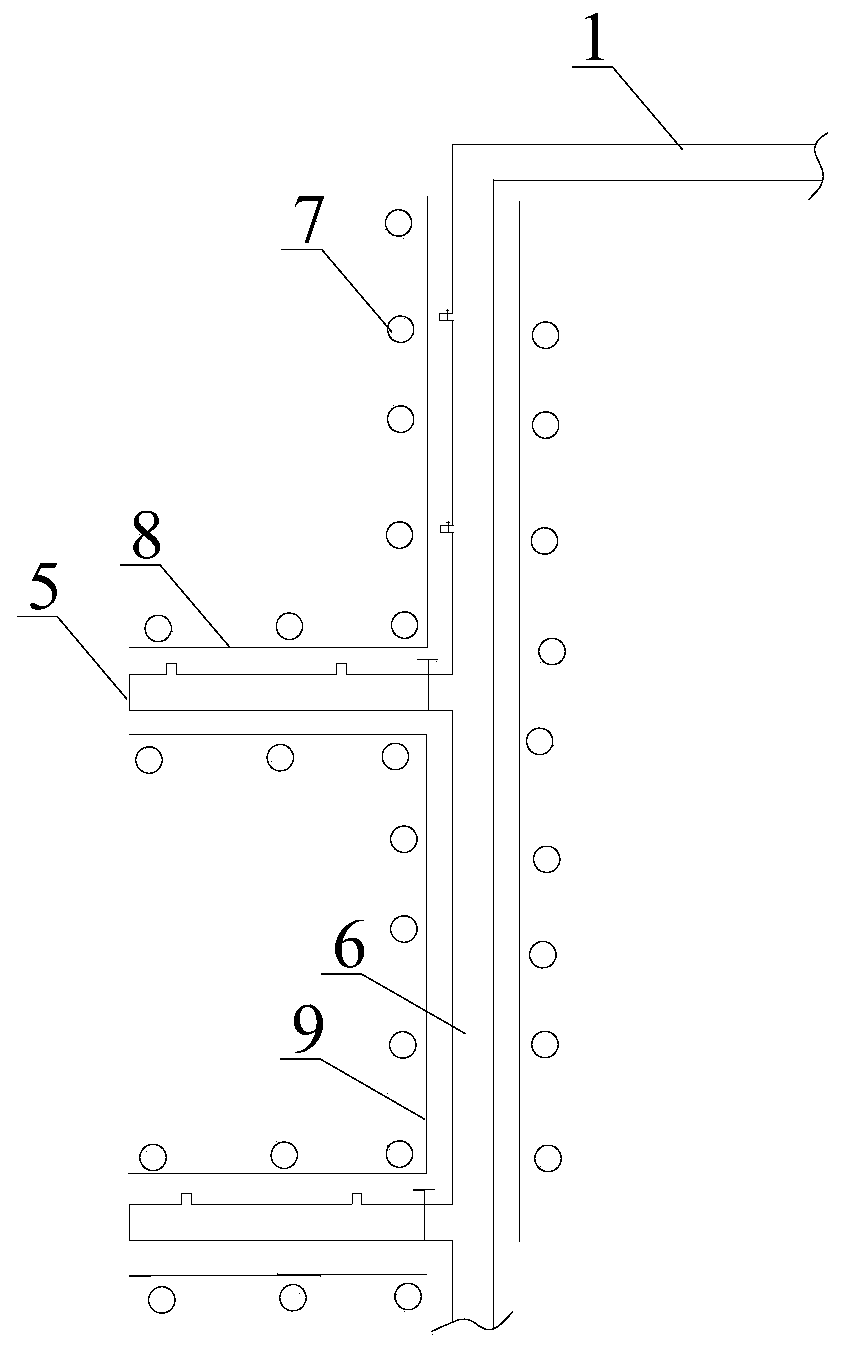

[0050] In this embodiment, the structure and construction method of the latitude and longitude filling system in the goaf are further described.

[0051] The latitude and longitude filling system in the goaf can construct a latitude and longitude filling body in the goaf, including gangue paste conveying pipe 1, mixer 2, filling pump 3, hydraulic support 4, direction filling pipe 5, inclined filling pipe 6, and wooden piles 7, move toward baffle plate 8, tend to baffle plate 9. The gangue paste conveying pipe is arranged in the transport tunnel 10, and transports materials in the transport tunnel 10. The mixer 2 and the filling pump 3 are connected through the paste conveying pipe, and the filling pump 3 is connected with the direction filling pipe 5 and the inclined filling pipe 6 through the paste conveying pipe 1. The mixer 2 stirs the materials to make gangue-like paste filling materials. Pump 3 pumps filling material to the working face. The direction filling pipe at th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com