Micro-perforating orthogonal distributed rectangular pipe clamping core sound and energy absorbing composite structure

A technology of composite structure and rectangular tube, which is applied in the direction of synthetic resin layered products, protective equipment, clothing, etc., can solve the problems of poor sound absorption effect, insufficient stiffness and strength, etc., and achieve the effect of light weight and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with accompanying drawing.

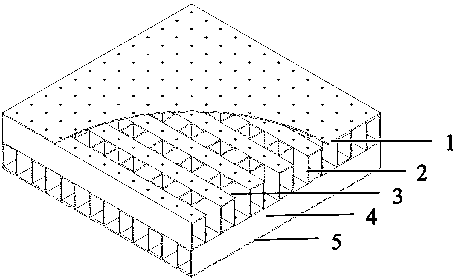

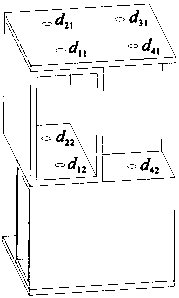

[0019] The present invention has micro-perforated orthogonally arranged rectangular tube sandwich sound-absorbing and energy-absorbing composite structure, such as figure 1 As shown, it includes an upper panel 1 sequentially connected from top to bottom, a first layer of horizontally arranged rectangular tubes 2, a second layer of horizontally arranged rectangular tubes 4 and a lower panel 5, and the first layer of horizontally arranged rectangular tubes 2 and the second layer of horizontally arranged rectangular tubes The second layer of horizontally arranged rectangular pipes 4 is a plurality of equidistant and orthogonally distributed rectangular pipes, and vertically arranged rectangular pipes 3 are distributed between adjacent rectangular pipes, and each part is welded or bonded to form an overall structure. There are sound-absorbing holes on the upper panel 1, the fir...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com