Optical deflection microscopic surface measuring device and method

A surface measurement and optical technology, applied in the field of measurement, can solve problems such as being susceptible to environmental interference, limited measurement range, and small measurement range, and achieve the effects of improving low spatial resolution, improving measurement accuracy, and simplifying calibration work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The present invention will be described in detail below in conjunction with the specific embodiments shown in the accompanying drawings, but these embodiments do not limit the present invention, those of ordinary skill in the art make structural, method, or functional changes based on these embodiments All are included in the scope of protection of the present invention.

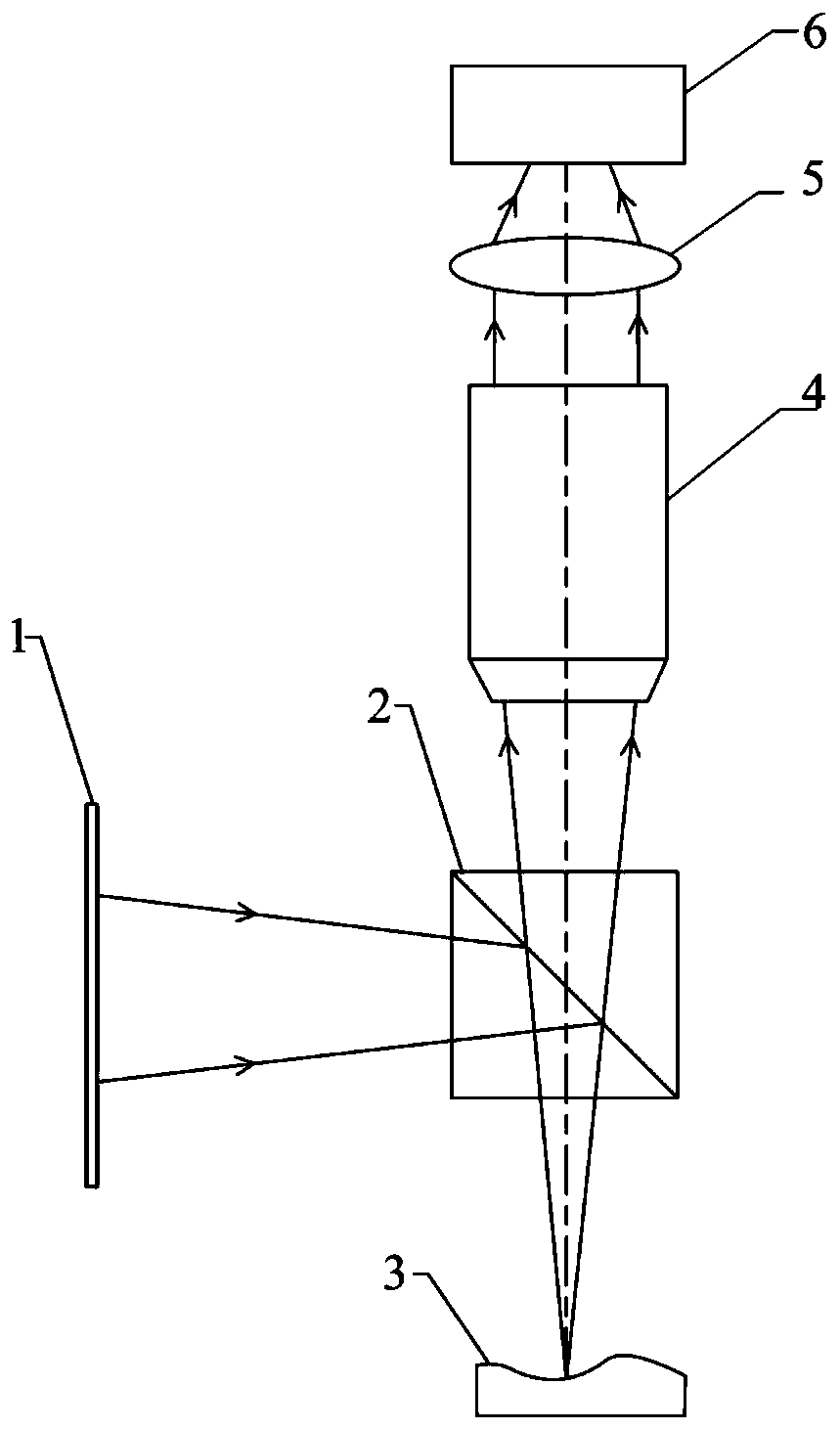

[0048] Such as figure 1Shown in an embodiment of the present invention, the optical deflection microscopic surface measurement device includes a projection screen 1, a beam splitting prism 2, an element to be measured 3, a microscopic objective lens 4, an imaging lens 5, a CCD detector 6 and a computer, Wherein, the component under test 3 is placed under the dichroic prism 2, the projection screen 1 is arranged on the left side of the dichroic prism 2 and the two are parallel, the microscopic objective lens 4, the imaging lens 5 and the CCD detectors 6 are sequentially arranged above the beam splitti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com