Test method for tribological characteristics of high-strength piston ring and cylinder liner in simulated service state

A service state and test method technology, applied in the field of test simulation, can solve the problems of large limitations of simulation experiments, difficult control of the bench, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention is described in more detail below in conjunction with accompanying drawing example:

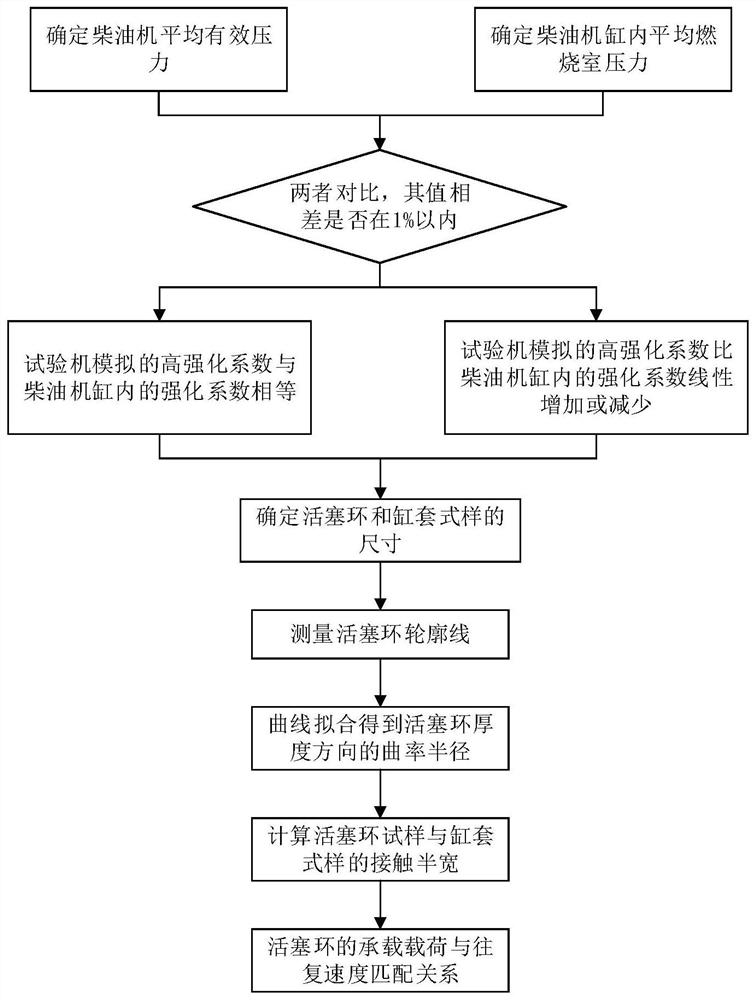

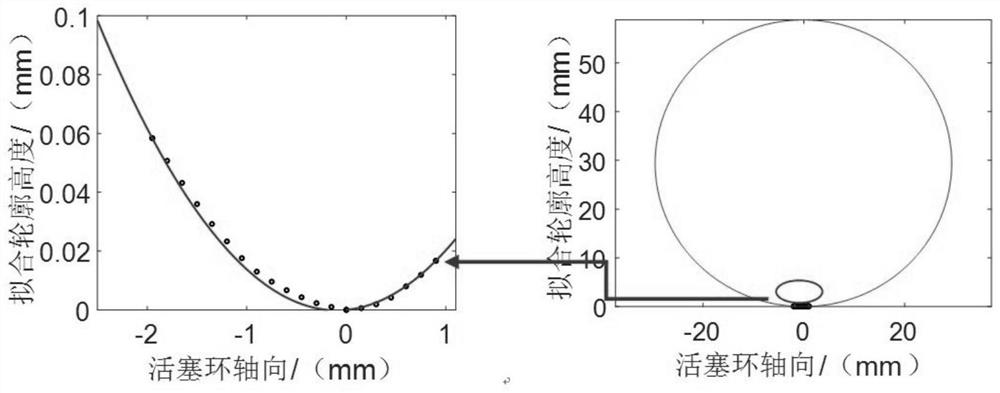

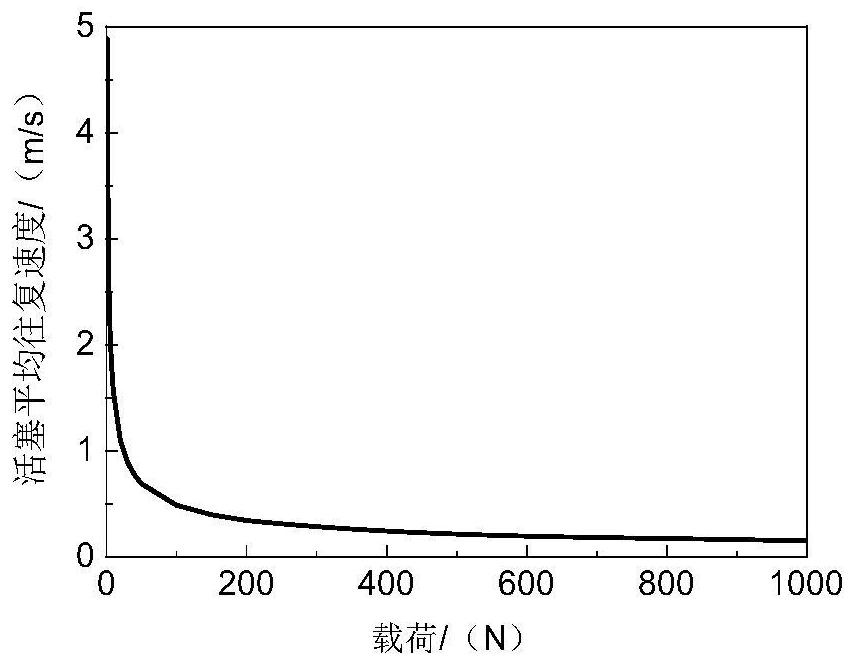

[0025] combine Figure 1-3 , the present invention comprises the following steps:

[0026] Step 1, determining the relationship between the average effective pressure and the average combustion chamber pressure under the actual working conditions of the diesel engine;

[0027] Collect the high intensification coefficient, average effective pressure, and combustion chamber pressure curves under the actual operating conditions of the diesel engine, and take the average value of the combustion chamber pressure, and compare the relationship between the two pressures.

[0028] The calculation formula of strengthening coefficient is S c =P e ×U, where Sc is the strengthening coefficient, Pe is the average effective pressure in the diesel engine cylinder, and U is the average speed of the piston ring

[0029] Step 2. If the difference between the average effective pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com