Insulation board processing technology and processing equipment thereof

A technology for processing equipment and thermal insulation boards, applied in the field of thermal insulation board processing technology and its processing equipment, can solve the problems of complex processing technology, simple structure of press machine, slow down processing progress, etc., achieve low cost, simple structure, and energy saving Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

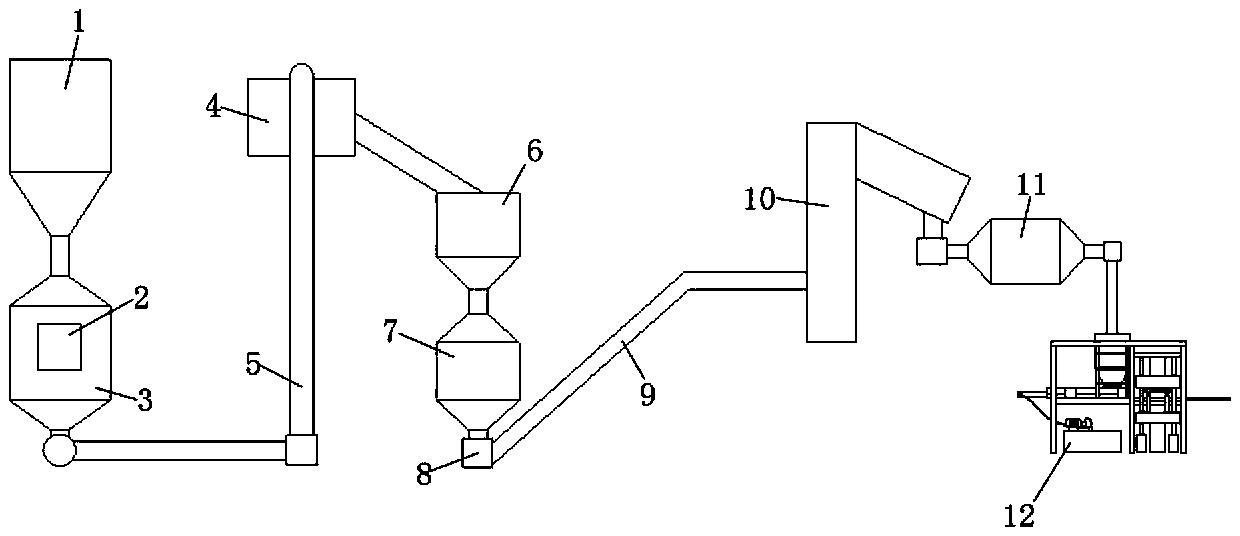

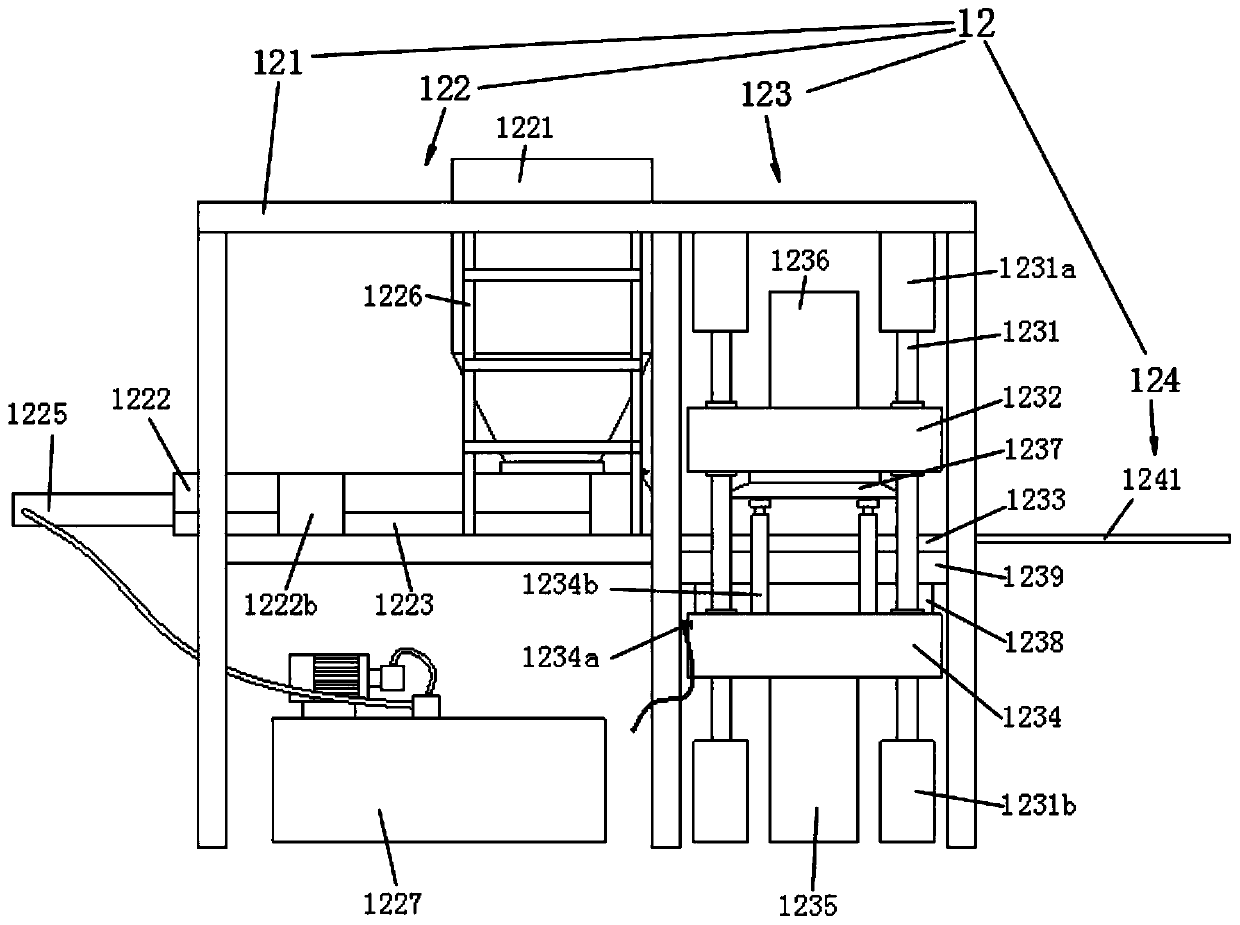

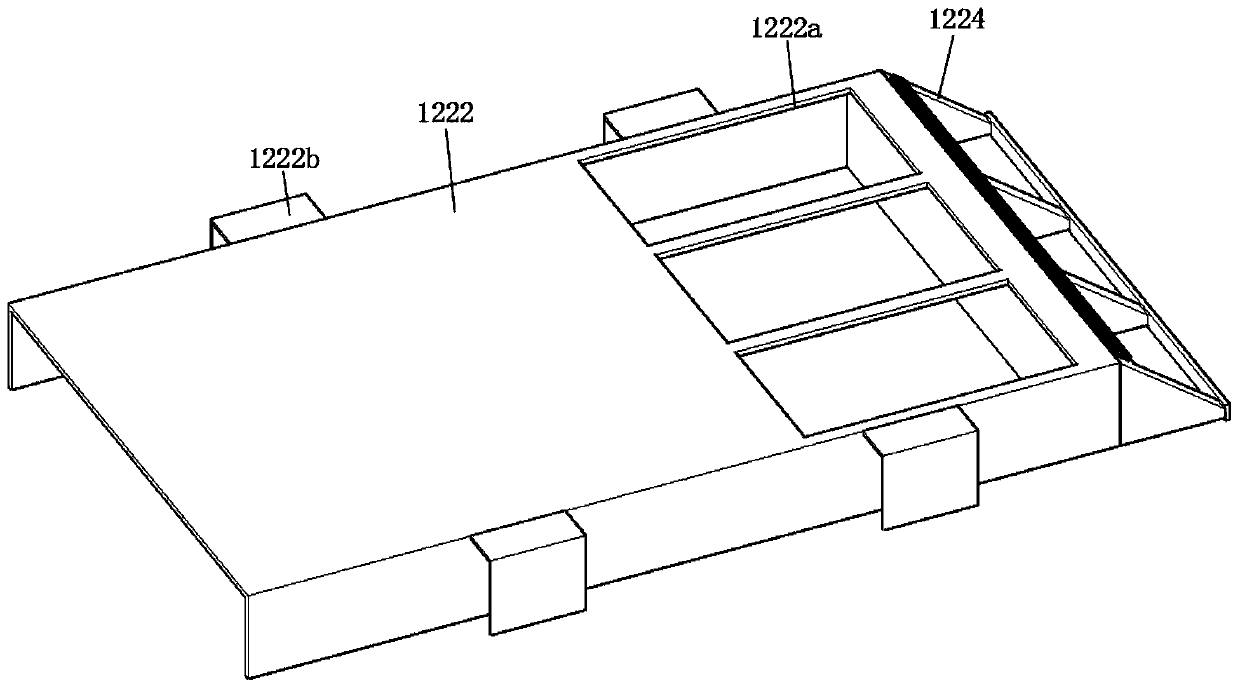

[0043] refer to figure 1 , this embodiment discloses a processing equipment for thermal insulation boards, including a plurality of side-by-side unloading tanks 1, a first weighing scale 2, a mixing tank 3, a first storage tank 4, a first hoist 5, a feeding Drum 6 , mixing bucket 7 , second weighing scale 8 , second hoist 9 , second storage tank 10 , rotating drum 11 and pressing molding machine 12 . The mixing tank 3 communicates with the feeding openings of a plurality of feeding tanks 1 . The mixed raw materials in the mixing tank 3 are transported to the first storage tank 4 through the first elevator 5 . The mixed material in the first storage tank 4 falls into the feeding cylinder 6 along the connecting pipe inclined downward. The mixing barrel 7 stirs and mixes the mixed materials delivered from the feeding barrel 6 . The stirred material in the mixing barrel 7 is transported to the second storage tank 10 through the second elevator 9 . The mixed material in the sec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com