Water-based color-changing heat-insulating glass paint and preparation method thereof

An insulating glass, water-based technology, applied in the field of coatings, to achieve the effects of low oil absorption, enhanced elasticity, and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

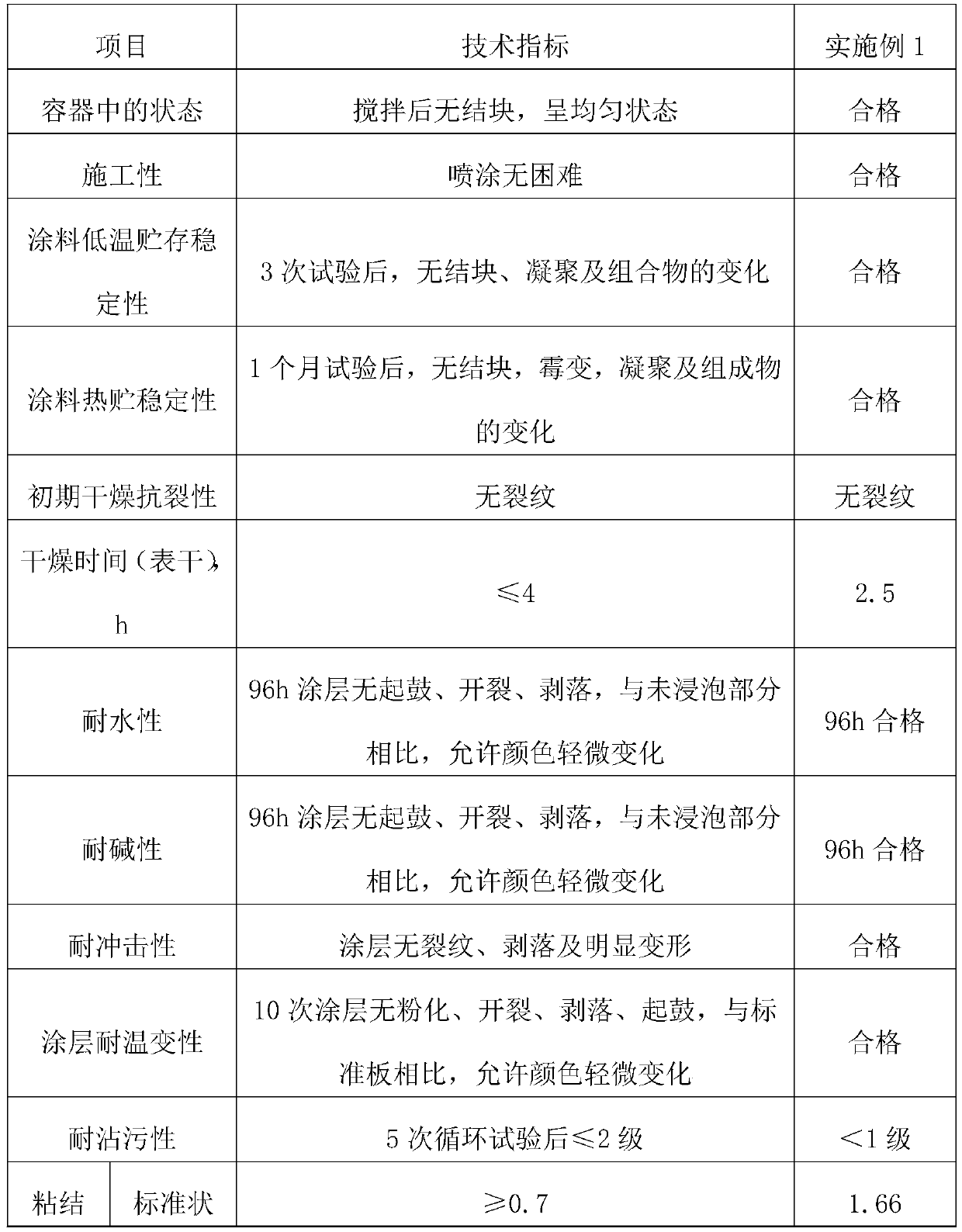

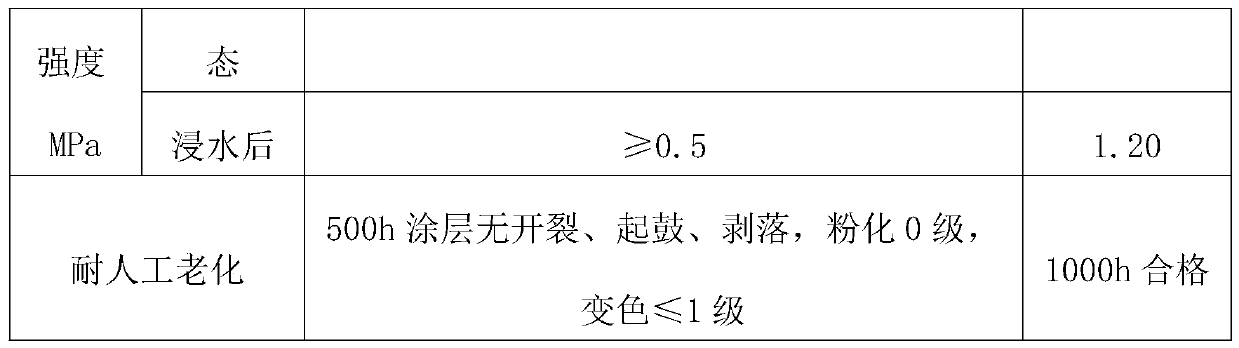

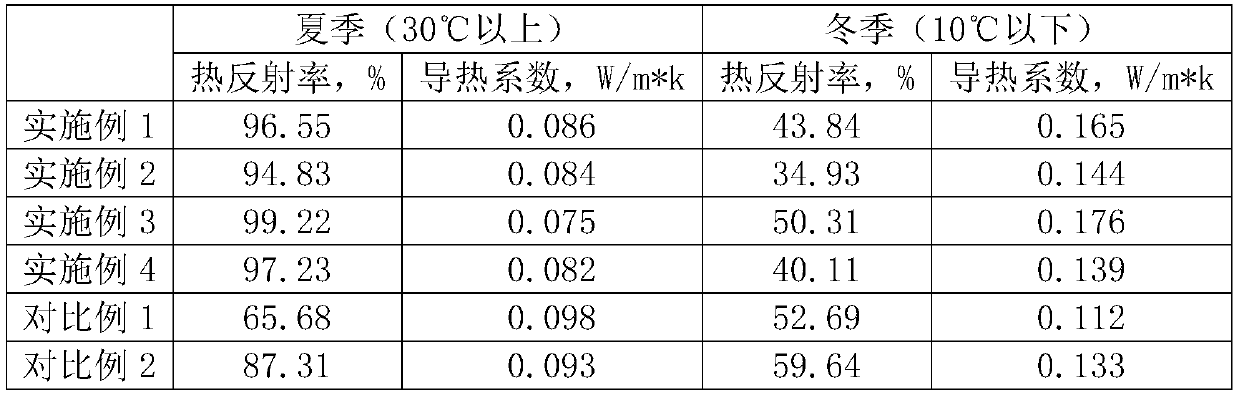

Examples

Embodiment 1-4

[0048] Formula: in parts by mass, as shown in Table 1.

[0049] Preparation method: comprising the following steps:

[0050] Step 1: weighing each component according to the above raw material ratio;

[0051] Step 2: Add distilled water into the reaction vessel, and at a stirring speed of 500-800rpm, add acrylic hydroxyl resin, solvent, distilled water, dispersant, heat-insulating nanoparticles, and color-changing fibers to the reaction vessel in sequence every 5 minutes;

[0052] Step 3: Add defoamer and thickener to the reaction vessel in turn, stir at a speed of 500-800rpm until the material is uniform, and obtain component A;

[0053] Step 4: Add the isocyanate curing agent into the reaction container, then add the high-boiling point solvent, and stir at a speed of 500-800rpm until the stirring is uniform, and then the B component is obtained;

[0054] The components A and B are packaged separately to obtain the water-based color-changing heat-insulating glass varnish. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com