Composite floor

A composite flooring and raw material technology, applied in ceramic molding machines, construction, manufacturing tools, etc., can solve the problems of easily exceeding the standard of formaldehyde content, easily exceeding the standard of harmful organic volatile content, human hazards, etc., and achieve good lubrication and stable chemical properties , to promote the effect of coloring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

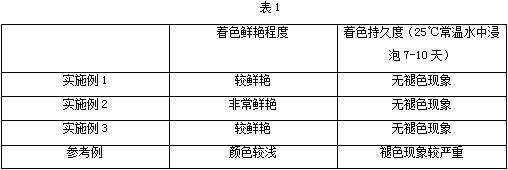

Examples

Embodiment 1

[0020] A composite floor, comprising the following raw materials in parts by weight: 40 parts of magnesium oxide, 14 parts of sawdust, 2 parts of wood fiber, 8 parts of coastal saline soil, 8 parts of diatom mud, 1 part of boric acid, 3 parts of pulp powder, and magnesium sulfate solution 60 parts, 1 part of inorganic glue, 1.2 parts of reinforcing agent, 1 part of colorant, 1 part of polyethylene wax.

[0021] Wherein, the inorganic glue is a solvent-free two-component polyurethane glue; the coastal saline soil is dehydrated and ground at a low temperature, the temperature of the low temperature dehydration is 10°C, and the water content of the coastal saline soil after dehydration is less than or equal to 5%, and the purpose of the coastal saline soil after grinding is The number is greater than or equal to 450 mesh; the concentration of magnesium sulfate solution is 40%.

[0022] The preparation method includes the following steps: (1) mixing and stirring the above-mentione...

Embodiment 2

[0027] A composite floor, comprising the following raw materials in parts by weight: 50 parts of magnesium oxide, 20 parts of sawdust, 6 parts of wood fiber, 10 parts of coastal saline soil, 12 parts of diatom mud, 2 parts of boric acid, 7 parts of pulp powder, and magnesium sulfate solution 70 parts, 3 parts of inorganic glue, 2.4 parts of reinforcing agent, 2 parts of coloring agent, 2 parts of polyethylene wax.

[0028] Wherein, the inorganic glue is a solvent-free two-component polyurethane glue; the coastal saline soil is dehydrated and ground at a low temperature, and the temperature of the low temperature dehydration is 16°C. After dehydration, the water content of the coastal saline soil is less than or equal to 5%. The number is greater than or equal to 450 mesh; the concentration of magnesium sulfate solution is 48%.

[0029] The preparation method includes the following steps: (1) mixing and stirring the above-mentioned raw materials in parts by weight to form a mix...

Embodiment 3

[0034] A composite floor, comprising the following raw materials in parts by weight: 45 parts of magnesium oxide, 17 parts of sawdust, 4 parts of wood fiber, 9 parts of coastal saline soil, 10 parts of diatom mud, 1.5 parts of boric acid, 5 parts of pulp powder, and magnesium sulfate solution 65 parts, 2 parts of inorganic glue, 1.8 parts of reinforcing agent, 1.5 parts of colorant, 1.5 parts of polyethylene wax.

[0035] Among them, the inorganic glue is a solvent-free two-component polyurethane glue; the coastal saline soil is dehydrated and ground at a low temperature, and the temperature of the low temperature dehydration is 13°C. After dehydration, the water content of the coastal saline soil is less than or equal to 5%. The number is greater than or equal to 450 mesh; the concentration of magnesium sulfate solution is 44%.

[0036] The preparation method includes the following steps: (1) mixing and stirring the above-mentioned raw materials in parts by weight to form a m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexural strength | aaaaa | aaaaa |

| water content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap