Tunnel pre-reinforcing and excavation construction method for crossing soil-rock boundary stratum

A construction method and pre-reinforcement technology, applied in tunnels, tunnel linings, earthwork drilling and mining, etc., can solve problems such as upper soil collapse, subsidence, and surrounding rock deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

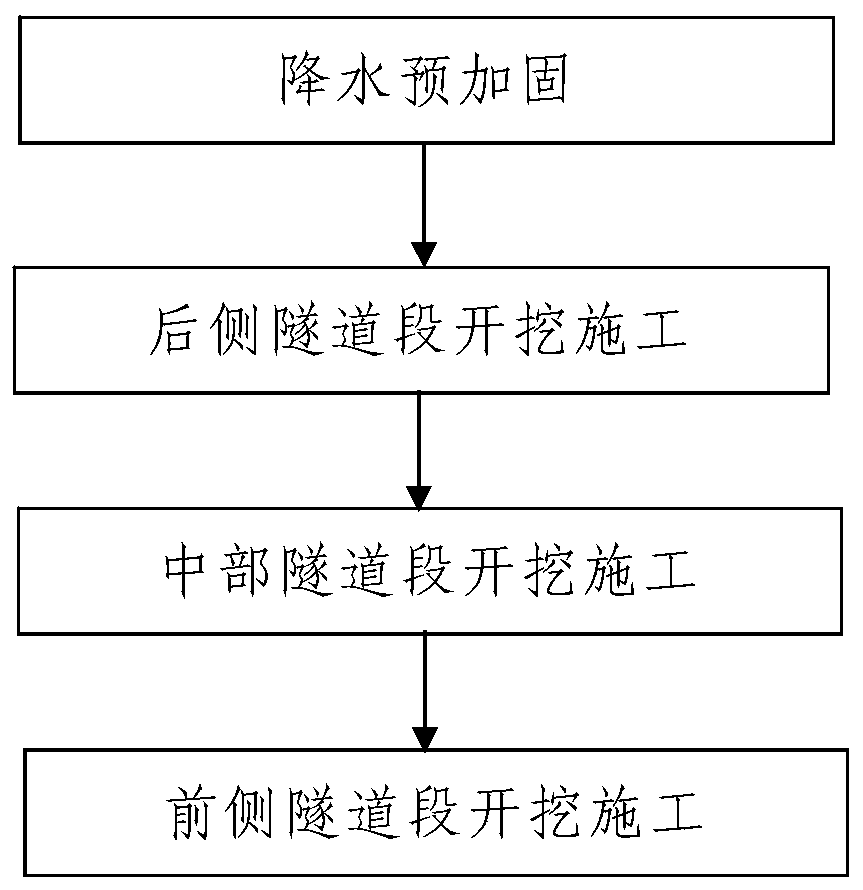

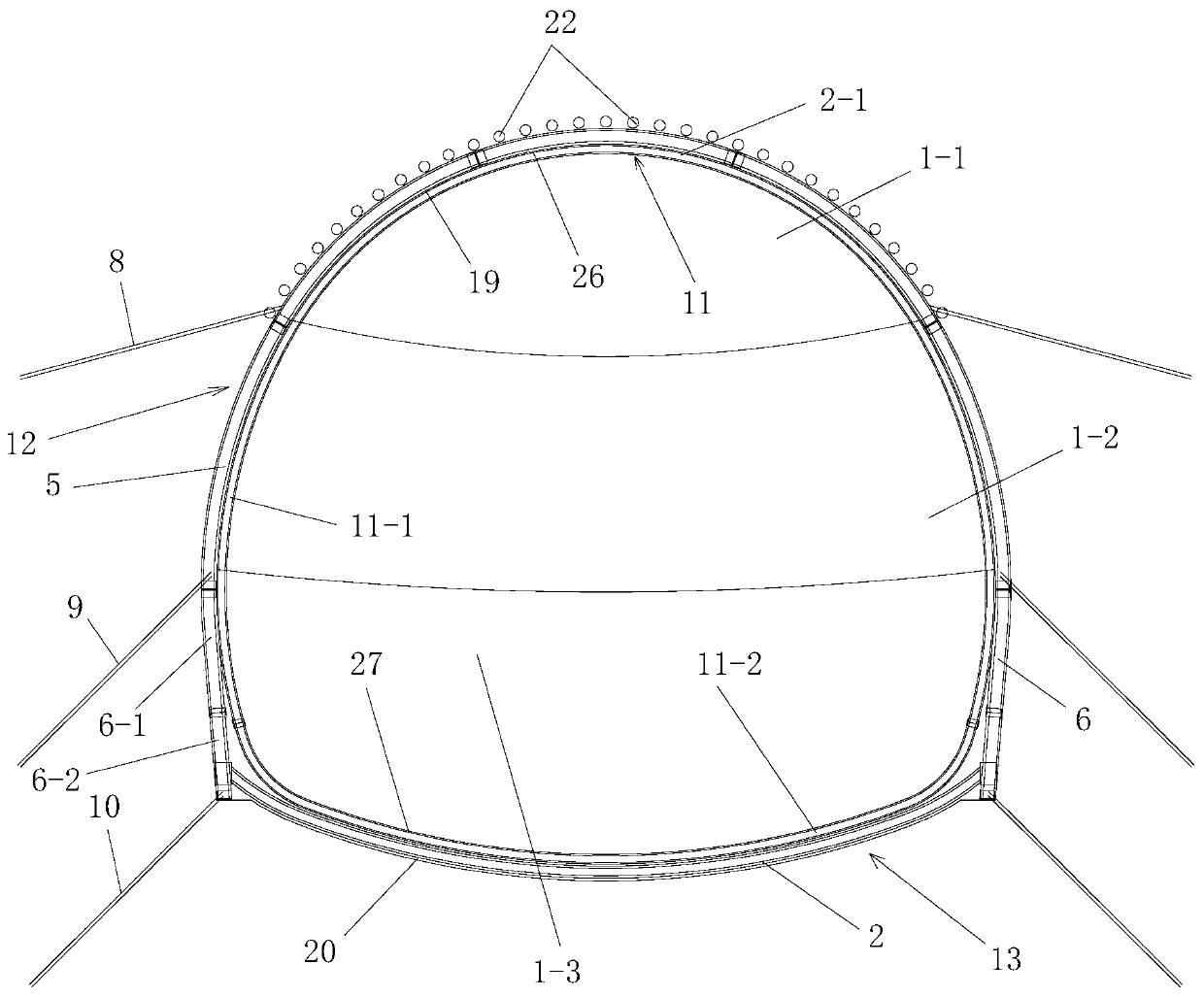

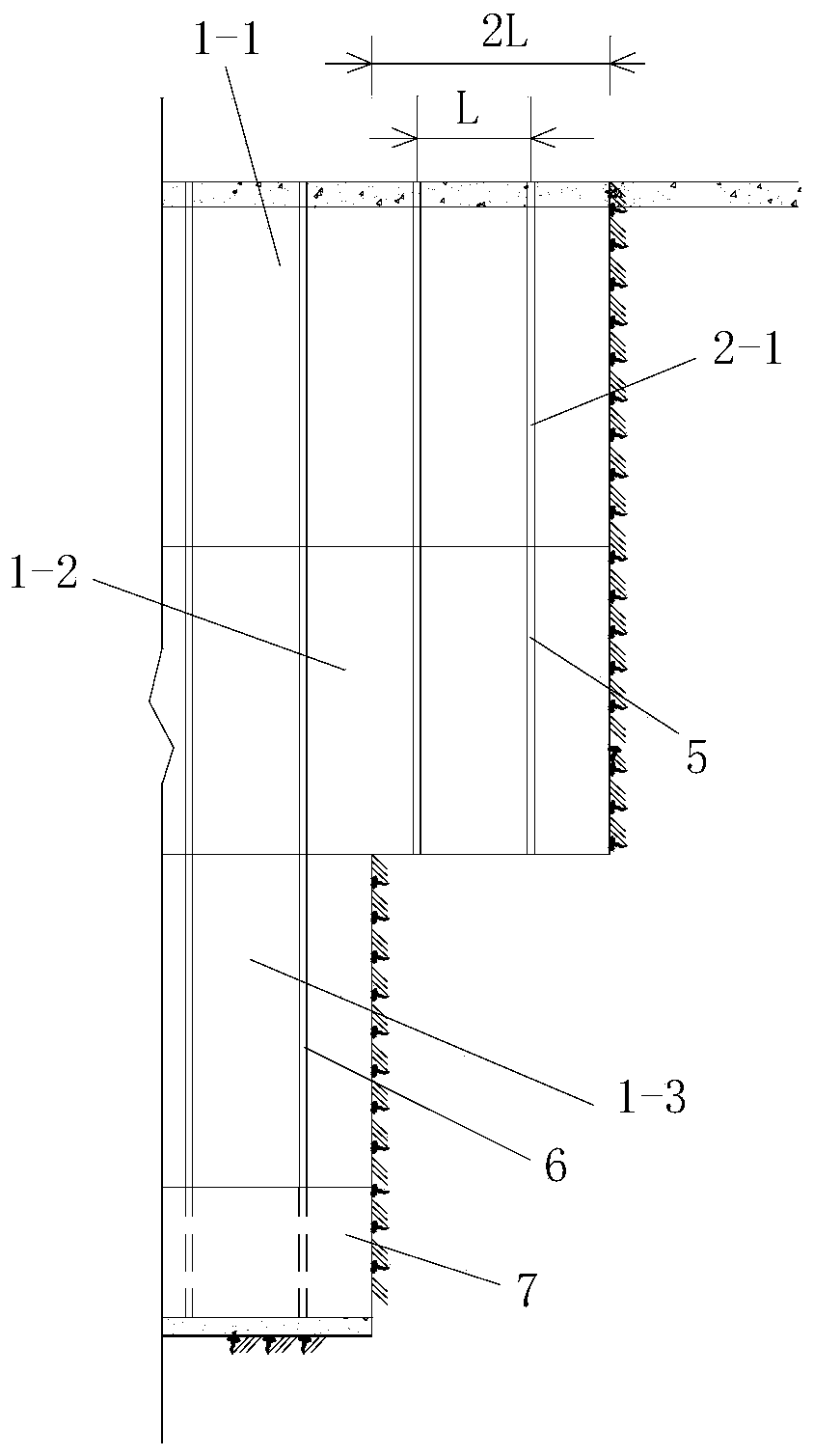

[0136] Such as figure 1 Shown is a tunnel pre-reinforcement and excavation construction method that passes through the earth-rock boundary stratum, and the tunnel to be constructed is a cross-section greater than 100m 2 And for the shallow buried tunnel located in the soil-rock boundary stratum, the surrounding rock grade of the tunnel hole 1 in the constructed tunnel is Grade IV or Grade V; Figure 7, the soil-rock boundary stratum comprises the loess layer 3 and the rock layer 4 below the loess layer 3, and the interface between the loess layer 3 and the rock layer 4 is an earth-rock interface; the tunnel hole 1 of the constructed tunnel is divided from top to bottom It is an upper cave body 1-1, a middle cave body 1-2 and a lower cave body 1-3. The upper cave body 1-1 is a cave body formed after excavating the upper steps of the constructed tunnel from back to front, The middle cave body 1-2 is a cave body formed after excavating the middle steps of the constructed tunnel ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com