Method for detecting migration amounts of volatile organic compounds in paper packaging material to dry simulants

A technology for volatile organic compounds and paper packaging materials, which is used in material separation, analysis materials, measuring devices, etc., can solve the problem that the migration amount cannot be directly detected, and improve the environmental friendliness of the method, the detection sensitivity, and the portability. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

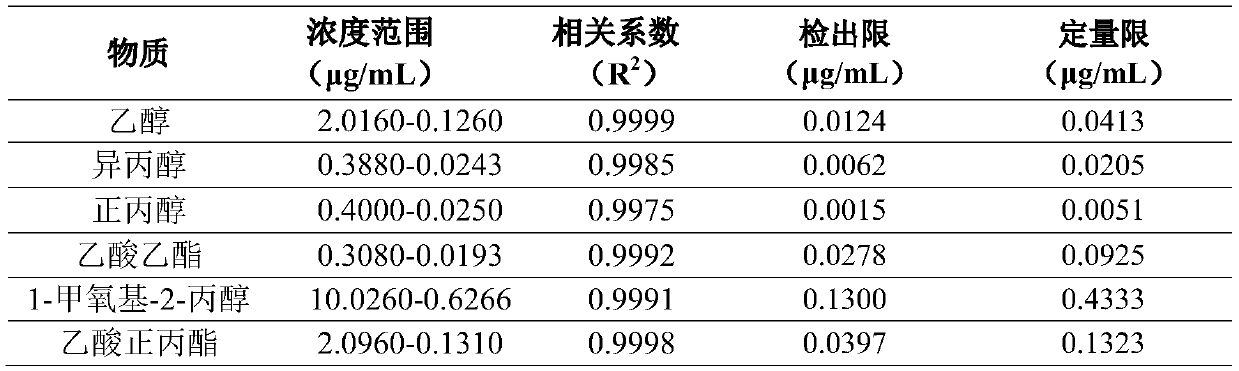

[0041] 1. Establish a standard working curve

[0042] Pipette 100mg of ethanol, 15mg of isopropanol, 15mg of n-propanol, 150mg of ethyl acetate, 500mg of 1-methoxy-2-propanol, and 100mg of n-propyl acetate into a 100mL volumetric flask, dilute to volume with water, and prepare Primary standard stock solution, sealed and stored away from light at 0℃~4℃.

[0043] Pipette 5mL of primary standard stock solution into a 100mL volumetric flask, dilute to volume with water, prepare secondary standard stock solution, and store in airtight and dark-proof conditions at 0°C to 4°C.

[0044]Accurately pipette 4mL, 2mL, 1.5mL, 1mL, 0.5mL, and 0.25mL of secondary standard stock solutions into a 100mL volumetric flask, and dilute to volume with water to obtain the standard working solutions of the six-level series.

[0045] Weigh 1g of Tenax in each of the six purging bottles, add 5mL of serial standard working solutions, shake on a vortex shaker (2000r / min) for 5min, centrifuge (5000r / min) ...

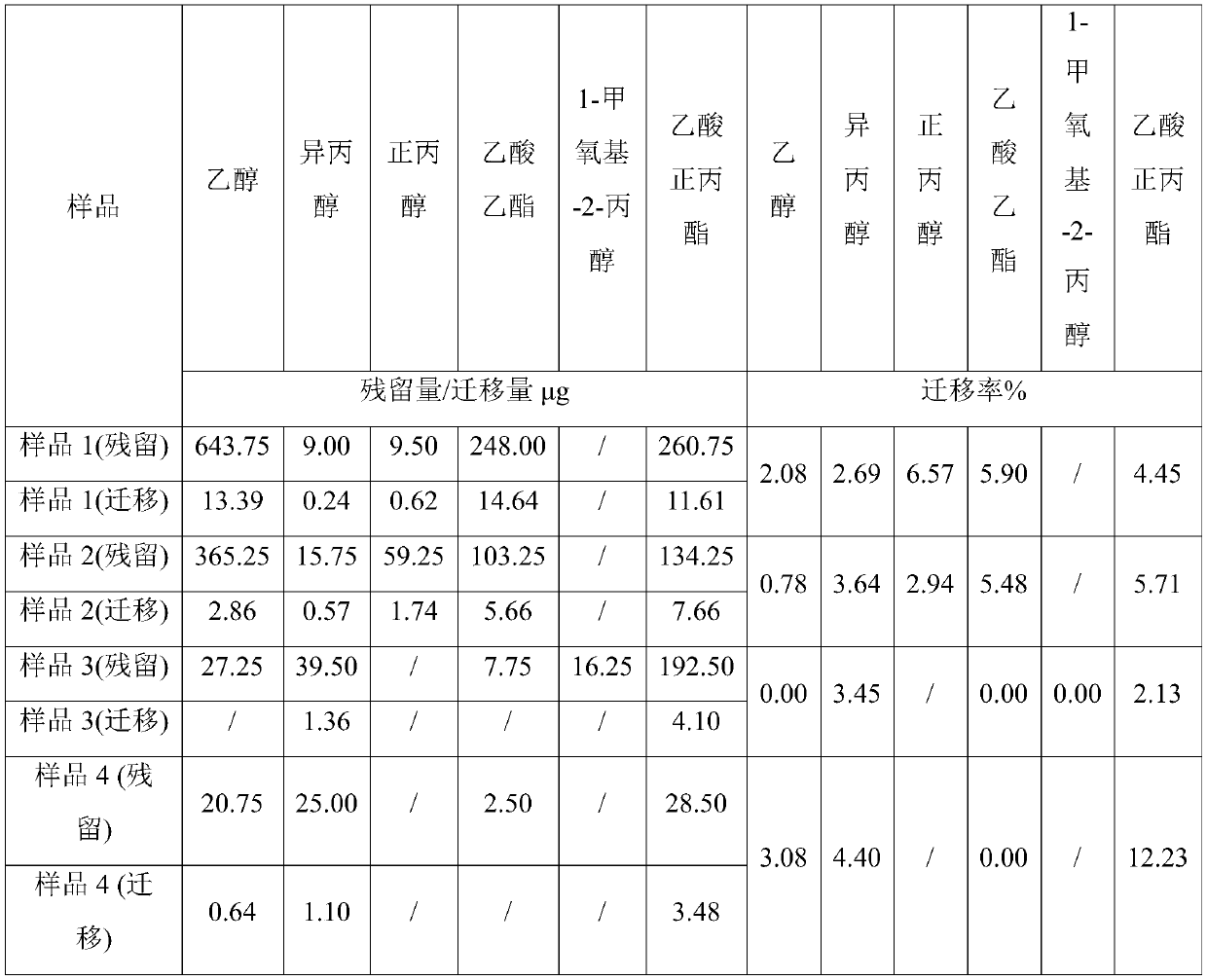

Embodiment 2

[0065] 1. Establish a standard working curve

[0066] Pipette 100mg of ethanol, 15mg of isopropanol, 15mg of n-propanol, 150mg of ethyl acetate, 500mg of 1-methoxy-2-propanol, and 100mg of n-propyl acetate into a 100mL volumetric flask, dilute to volume with water, and prepare primary Standard stock solution, sealed and stored away from light at 0℃~4℃.

[0067] Pipette 5mL of primary standard stock solution into a 100mL volumetric flask, dilute to volume with water, prepare secondary standard stock solution, and store in airtight and dark-proof conditions at 0°C to 4°C.

[0068] Accurately pipette 4mL, 2mL, 1.5mL, 1mL, 0.5mL, and 0.25mL of secondary standard stock solutions into 100mL volumetric flasks, and dilute to volume with water to obtain the sixth-level series standard working solutions.

[0069] Weigh 1g of Tenax in each of the six purging bottles, add 5mL series of standard working solutions, shake on a vortex shaker (2000r / min) for 5min, centrifuge (5000r / min) for 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com