Coal shale adsorption/desorption evaluation experiment simulation training system and teaching and practice method

An experimental and shale technology, applied in the field of coal shale adsorption/desorption evaluation experiment simulation training system, can solve the problems of high cost, single means, and few students' hands-on ability, and achieve the effect of reducing errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0083] The present invention introduces virtual simulation technology into the teaching course of coal shale adsorption / desorption evaluation experiment, and provides a virtual reality scene and an online learning platform for users to determine the purpose of the experiment and master the experimental process. The specific implementation steps are as follows:

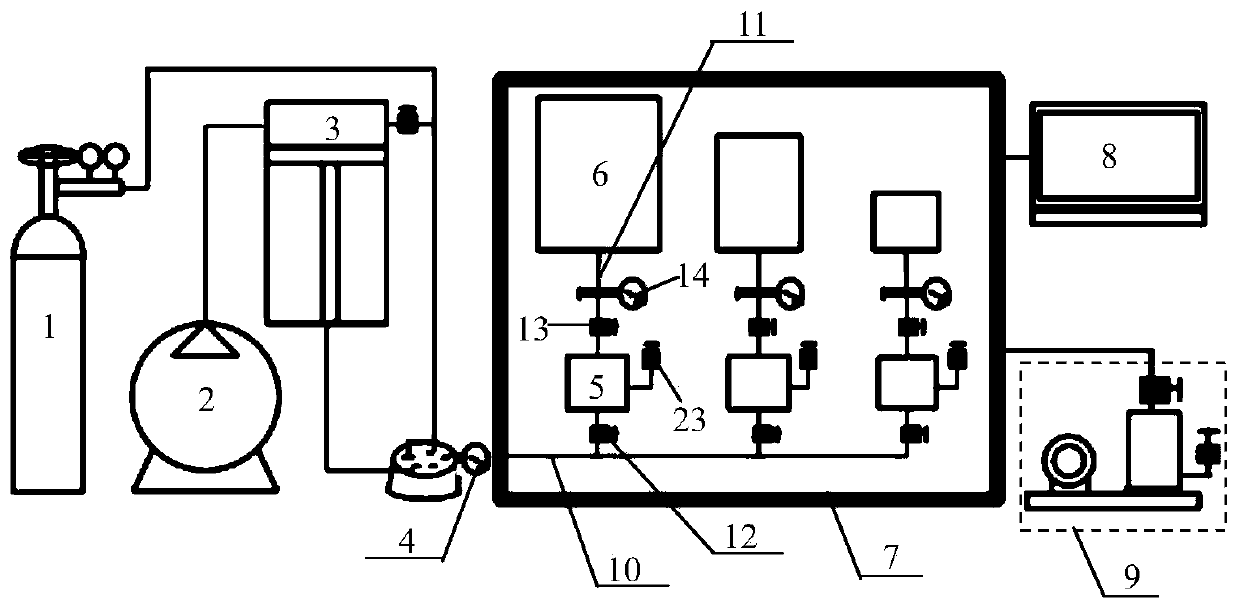

[0084] Step S1: Establish a virtual experimental material library, and use Maya and 3DMax software to complete the 3D modeling of experimental materials and equipment. The modeling process is an existing relatively mature technology, which will not be described here, including but not limited to the following 3D animation components: Coal shale sample library, gas source library, pressurization device, standard room, sample room, temperature control system, pressure sensor, data acquisition and processing system, vacuum pump, etc.;

[0085]Step S2: Establish an experimental design module, use Visual C++ to identify and ...

Embodiment 2

[0111] The experimental process of dynamic desorption-flow characteristics of shale powder is as follows:

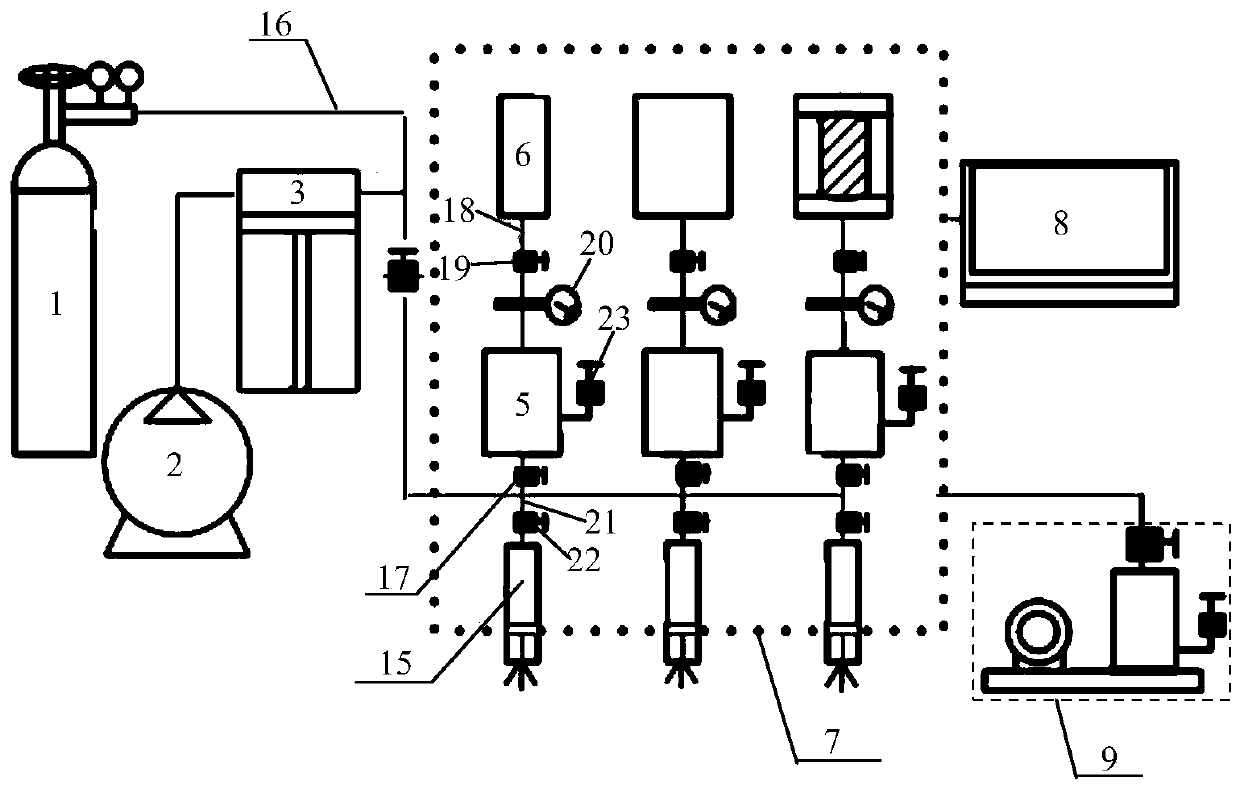

[0112] (a) Select the 3D animation component, and follow the figure 2 Build a dynamic desorption-flow evaluation experimental device, the main components include: gas source 1, booster system (including air compressor 2 and booster pump 3), manual metering pump 15, standard room 5, sample room 6, temperature control system 7 , data acquisition and processing system 8, vacuum pump 9, various pipelines and valves, etc., the gas source 1 is connected to the inlet of the standard chamber 5 through the pipeline three 16, the air compressor 2 and the booster pump 3 are connected to the pipeline three 16, Pipeline three 16 is provided with valve three 17, the outlet of standard chamber 5 is connected to the inlet of sample chamber 6 through pipeline four 18, valve four 19 and pressure sensor two 20 are arranged on pipeline four 18, standard chamber 5 is also connected through ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com