Method of repairing soft package swollen battery cell

A repair method and inflation technology, which are applied in the repair/maintenance of secondary batteries, circuits, electrical components, etc., can solve problems such as affecting battery performance, batteries can no longer be used, and cannot eliminate gas, etc., to achieve performance recovery, energy saving, Avoid scrapping effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

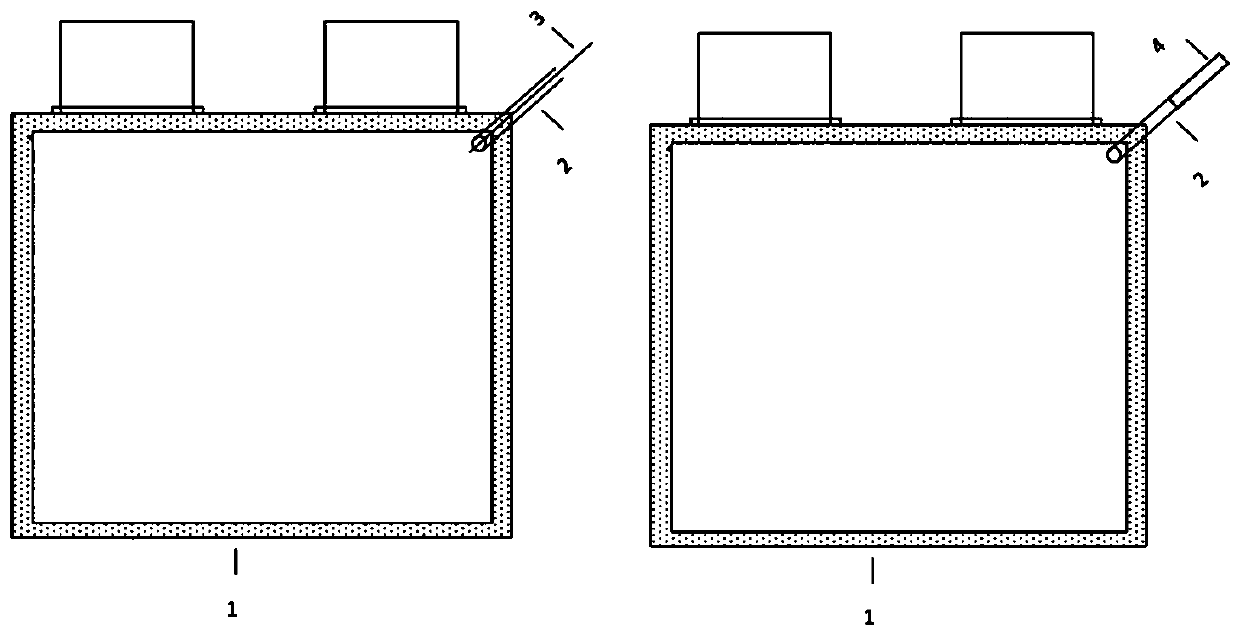

[0036] Embodiment 1 provides a repair method for a soft-pack air-expandable cell 1, comprising the following steps:

[0037] a. Place the soft-pack air-expandable cell 1 on a flat surface, and use a sharp object to pierce a small hole along the edge of the aluminum-plastic film at the junction of the top-seal and side-seal of the soft-pack air-expandable cell 1, and discharge the inside gas;

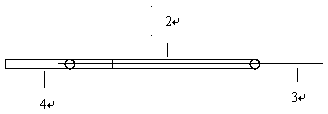

[0038] b. Insert the PP hose 2 into the small hole, seal along the edge of the small hole, fuse the PP layer inside the aluminum-plastic film with the PP hose 2, and draw out the copper wire 3;

[0039] c. Connect the PP hose 2 to the liquid supply device for rehydration, clamp the PP hose 2 with a clamping device, and put on the rubber cap 4;

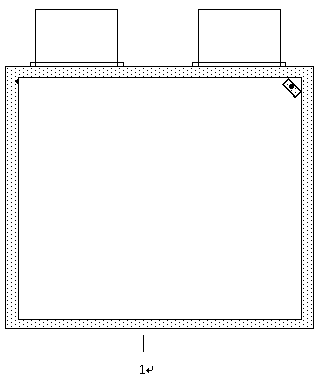

[0040] d. After the soft-pack air-expandable cell 1 is left at room temperature, connect the PP hose 2 to a vacuum pump, vacuumize the interior of the soft-pack air-expandable cell 1, and clamp it with the clamping device After the PP hose 2, p...

Embodiment 2

[0058] Embodiment 2 provides a repair method for the soft-pack air-expandable cell 1, comprising the following steps:

[0059] a. Place the soft-pack air-expandable cell 1 on a flat surface, and use a sharp object to pierce a small hole along the edge of the aluminum-plastic film at the junction of the top-seal and side-seal of the soft-pack air-expandable cell 1, and discharge the inside gas;

[0060] b. Insert the PP hose 2 into the small hole, seal along the edge of the small hole, fuse the PP layer inside the aluminum-plastic film with the PP hose 2, and draw out the copper wire 3;

[0061] c. Connect the PP hose 2 to the liquid supply device for rehydration, clamp the PP hose 2 with a clamping device, and put on the rubber cap 4;

[0062] d. After the soft-pack air-expandable cell 1 is left standing at room temperature, connect the PP hose 2 to a vacuum pump, vacuumize the interior of the soft-pack air-expandable cell 1, and clamp it with the clamping device After the P...

Embodiment 3

[0082] Embodiment 3 provides a repair method for the soft-pack air-inflatable cell 1, comprising the following steps:

[0083] a. Place the soft-pack air-expandable cell 1 on a flat surface, and use a sharp object to pierce a small hole along the edge of the aluminum-plastic film at the junction of the top-seal and side-seal of the soft-pack air-expandable cell 1, and discharge the inside gas;

[0084] b. Insert the PP hose 2 into the small hole, seal along the edge of the small hole, fuse the PP layer inside the aluminum-plastic film with the PP hose 2, and draw out the copper wire 3;

[0085] c. Connect the PP hose 2 to the liquid supply device for rehydration, clamp the PP hose 2 with a clamping device, and put on the rubber cap 4;

[0086] d. After the soft-pack air-expandable cell 1 is left standing at room temperature, connect the PP hose 2 to a vacuum pump, vacuumize the interior of the soft-pack air-expandable cell 1, and clamp it with the clamping device After the P...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com